Understanding Precast Concrete Electric Pole

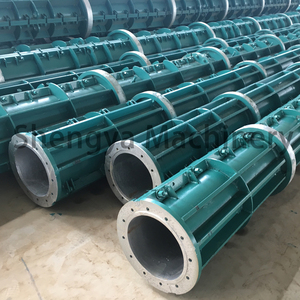

Precast concrete electric poles are engineered products designed for durability and efficiency in electrical transmission and distribution. They provide a robust alternative to traditional wooden or steel poles, making them an ideal solution for a variety of applications in power supply infrastructure. These poles are molded in a controlled factory environment, ensuring superior quality and consistency.

Types of Precast Concrete Electric Poles

Precast concrete electric poles come in several types, each tailored to meet specific infrastructural needs:

- Standard Utility Poles: Typically used for overhead power lines, these poles are designed to support utility cables and distribution lines.

- High Voltage Poles: Engineered for high voltage transmission, these poles can withstand extreme weather and loads.

- Decorative Poles: Aesthetic poles designed for urban areas; they enhance the visual landscape while serving electrical purposes.

- Braced Poles: These are designed with additional support and are often used in areas where wind resistance is a concern.

Applications of Precast Concrete Electric Poles

With their versatility and strength, precast concrete electric poles have a wide range of applications:

- Power Distribution: Ideal for distributed electrical networks in urban, suburban, and rural settings.

- Street Lighting: Often used in city infrastructure to support streetlights, ensuring adequate lighting for safety and visibility.

- Telecommunication Lines: Many telecommunication cables can be strung alongside electric wires on these sturdy poles.

- Renewable Energy Projects: Used to support structures for solar panels and wind turbines in sustainable energy projects.

Features and Advantages of Precast Concrete Electric Poles

The features and advantages of precast concrete electric poles make them a standout choice in electrical infrastructure:

- Durability: Made to withstand harsh weather conditions, including heavy winds, rain, and snow.

- Low Maintenance: Unlike wooden poles that may rot and require frequent replacement, precast options last longer and require minimal upkeep.

- Cost-Effective: While the initial investment may be higher, the longevity and reduced maintenance costs make them a cost-effective solution over time.

- Customizable: Precast poles can be manufactured in various shapes, sizes, and finishes to fit the specific needs of a project.

- Environmentally Friendly: Utilizing precast concrete reduces the need for deforestation and supports sustainable building practices.