(2732 products available)

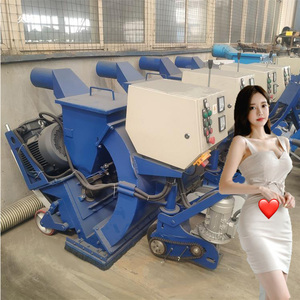

A portable shot blasting machine is a type of equipment used to clean the surfaces of small workpieces. The belt or table blasting machine is suitable for large or medium workpieces but is also bulky. Many manufacturers prefer the portable machines, which are called blast pots. They are lightweight, and the customer can choose the size and weight to suit their needs. These types of machines are all-in-one solutions. The blast pot includes a pressure vessel for the abrasive and air controls and holds the air compressor, the air delivery nozzle, and air regulator for the blast nozzle.

Portable shot blasting machines can also be classified according to the medium that they use, as mentioned before. Many metal fabrication manufacturers manually use tools to prepare the metal for coating or painting. The portable machines are ideal for these manufacturers as they can be used to remove rust before any protective coatings are applied to the metal. Their portability means that no rust areas go untreated, and the quality of the job is improved.

Portable shot blasting machines are also classified according to whether they are suction or pressure blast pots. Generally, pressure pots are more common than suction pots, which are also called pull-along blasters. Long hoses connect pressure pots to the air compressors, while suction pots are on the equipment that needs blasting. Pull-along blasters require less abrasive than pressure pots.

The common practice is to mount the abrasive container in a pressure form. This pressure form holds the container in a cylindrical form and is connected to a hose that transports the air. When the air is blasted through the hose, the abrasive material is forced through the nozzle at high pressure.

Specifications of a typical 60L portable shot blasting machine include:

Maintenance tips:

Portable shot blasting machines are crucial in surface preparation for various industries and applications. Here are some common applications of portable shot blasting machines:

Steel Surface Preparation

Portable shot blasting machines are widely used in the steel industry to remove contaminants on steel surfaces such as scales, rust, and oxides. They are great for preparing substrates for coatings or structural and vessel steel fabrication.

Coating Removal

Businesses use portable shot blasting machines to remove coatings, including paints, varnishes, and epoxies, from various substrates. This is common in the maritime, automotive, and aerospace industries.

Surface Cleaning

Manufacturers use portable shot blasting machines for surface cleaning operations. The process usually involves removing dust, sand, and slag from metal castings, molds, and dies. It can also eliminate welding spatter, making it easier for subsequent manufacturing and assembly processes to take place.

Surface Roughening

Portable shot blasting machines are used when a roughened surface is required for better adhesion of coatings, paints, or adhesives. This is mostly the case in the bonding of materials in construction and civil engineering.

Surface Finishing

Some portable shot blasting machines have specific blasting media for achieving distinct surface finishes, like matte, satin, or polished textures. The preferred finish is mostly based on the subsequent use of the item.

Rust Removal

Portable shot blasting machines effectively remove rust from various metal surfaces. Rust removal, also known as derusting, prolongs the lifespan of equipment, machinery, and structures.

Grit Removal

Portable shot blasting machines can remove blasting grit from uneven surfaces. The method of removal is not only fast but efficient compared to manual methods.

Asphalt and Concrete Cleaning

In the construction industry, portable shot blasting machines are used for the removal of asphalt from roadways and contaminates like grease concrete. The machine can also be used to prepare road surfaces before repairs.

Stamping and Embossing Removal

Portable shot blasting machines are used to remove stamping and embossing marks from various surfaces, including metal sheets and plates. Using the machine makes it easy to achieve uniform and smooth surfaces.

There are several factors business buyers should consider when choosing portable shot blasting machines for sale. The first factor is the type of shot to be used in the machine. As previously explained, different shots have unique benefits and uses. What may work for one surface or item may not be effective for another. Therefore, surface needs and item geometries must align with the blasting media's qualities to achieve the desired results.

The capacity of the machine should also play a role in decision-making. Buyers must consider the machine's capacity and how it will impact their blasting needs. The table/veyor capacity indicates how much work can be done in a single session. This further affects the overall production rate. A steady flow of work requires a blasting machine with high capacity to maintain efficiency and minimize downtime.

Furthermore, the efficiency of the machine should be considered. Production demands require blasting machines that resolve issues quickly and effectively. Energy consumption and recovery systems play a large role in the machine's overall efficiency. It is important to note that efficient machines can lower operating costs and enhance productivity.

The ease of use of the machine is also crucial. User-friendly features like intuitive controls, adjustable settings, and ergonomic design contribute to smooth operation and minimize training time.

Finally, employers must consider the health and safety of their employees. Blasting jobs pose inherent risks, especially when working with hazardous materials like asbestos. Employers must work to protect their employees, and buying a machine with safety features can go a long way in ensuring this. Safety features like dust containment systems, noise reduction measures, and proper shielding help protect workers from health hazards and risks associated with blasting operations.

Q1 What kind of surfaces can portable shot blasting machines work on?

Normally, they can work on various surfaces, including concrete, asphalt, steel, fiberglass, and mill-scale surfaces, among others.

Q2 How does portable shot blasting machine work?

It works by blasting the surface with steel shots through centrifugal force. The steel shots will then clean the target surface before falling into the shot recovery system.

Q3 How portable is a portable shot blasting machine?

They are often mounted on a wheeled cart or lifted and suspended from an overhead crane or hoist.

Q4 How safe is portable shot blasting machine?

The machine is safe as long as the operators use the recommended personal protective equipment (PPE), including hearing protection, respirators, face shields, and safety goggles.