(9389 products available)

There are several types of polyethylene plastic, and each type has different applications and purposes based on the needs of the consumers. The following are the types of polyethylene:

Each of the above types of polyethylene has applications and products designed to meet specific requirements and standards. The 20mm polyethylene sheet comes in different colors, such as gray, black, and white, and is designed to resist UV radiation.

When considering polyethylene 20mm products, it's important to understand their advantages, applications, and how they differ from other materials. Here are some key features and functions:

Thickness and Density:

One of the most important qualities of this material is its thickness. At 20mm, it provides a robust and durable surface that can withstand significant wear and pressure. Its thickness makes it ideal for applications requiring a strong barrier or surface, such as in construction projects. PE is known for its lightness and flexibility, making it a popular choice for various uses. However, a denser and thicker form is better suited for applications that demand durability and strength.

Durability:

Durability is another essential quality of polyethylene. The material can survive a variety of environmental conditions without breaking or degrading. This durability makes it a popular choice for uses in agriculture and construction, where weather and other environmental elements are at play.

Impact Resistance:

PE has excellent impact resistance. The 20mm thickness adds to its ability to withstand sharp blows or force without breaking or splitting. This quality makes it suitable for applications in construction, where sheets or boards may need to be struck by hard objects.

Corrosion Resistance:

This material is resistant to corrosion. It does not rust or corrode, making it an excellent choice for applications near water or in wet environments. The 20mm thickness provides a solid barrier against moisture, ensuring the material remains intact over time.

UV Resistance:

Polyethylene's UV resistance is one of its important qualities. When exposed to sunlight or ultraviolet radiation, the 20mm form does not deteriorate or become brittle. This characteristic makes it a popular choice for outdoor applications, such as lining ponds or creating barriers.

Flexibility:

When discussing qualities of polyethylene, flexibility is an important factor. Despite its thickness, the polymer can bend and fold without breaking. This flexibility is useful in applications such as creating curves in landscaping or lining ponds.

The use of polyethylene 20mm is common in several industries. The reason for its high applicability is because of its high-density nature and its durability. In this section, we will look at some of its usage.

Agricultural

HDPE sheets are used in the construction of chemical storage tanks. They are also used in the construction of water tanks and silos. This is because they cannot be affected by chemicals and are also corrosion-resistant. The sheets are also used in the construction of canals, irrigation ditches, and drainage systems. This is because they create a waterproof lining that helps reduce water wastage.

Packaging

PE is used in creating plastic bags. These include garbage bags, retail bags, and food storage bags. These plastic bags are popular because they are lightweight, flexible, and durable. They are also reusable and recyclable. Polyethylene films are also created from this material. These are thin, flexible sheets of plastic used for packaging food items, products, and agricultural applications.

Construction

Polyethylene is used in the construction of vapor barriers. These are sheets of polyethylene 20mm thick that are placed under floors and above ground to prevent moisture from getting into the building. Polyethylene is also used in the construction of geomembranes. These are used in landfills to prevent leachate from contaminating the ground.

Manufacturing

HDPE is used in the construction of bottles, containers, and jars. This is because it can be molded into different shapes. Polyethylene is also used in the construction of caps and lids. It is also used in making industrial containers with a capacity of up to 30 liters.

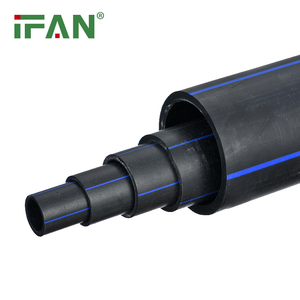

Oil and Gas

Polyethylene 20mm is used in the construction of pipelines. These are more than 3mm thick pipes used to transport water and natural gas. They are preferred since they are rust-resistant and can easily be bent when exposed to heat. Thin polyethylene pipes are also used in the drainage system. These are less than 3mm thick and are preferred due to their smooth interior.

Consumer Goods

Polyethylene is used in the construction of various household items. For instance, it is used in recycling bins, toys, and kitchen containers. It is also used in manufacturing stationery products like plastic envelopes and file holders.

The following are some key factors that retailers should consider when sourcing for polyethylene 20mm products:

Applications

Retailers should get 20mm polyethylene products suitable for various applications. For instance, those suitable for packaging and construction. The former is ideal for packaging bags, sacks, and containers. The latter is suitable for geomembranes, pipes, and plastic sheets. Furthermore, different applications require different properties. Thus, they should check the specifications to ensure the product is suitable for the intended application. For instance, the HDPE has a high impact resistance, which makes it ideal for packaging. On the other hand, LDPE is more flexible and suitable for making containers.

Consider the durability and strength

When sourcing for polyethylene, buyers should check the durability and strength characteristics. They should look for options with high durability and strength ratings. This ensures the polyethylene products can withstand various conditions, such as pressure, environmental hazards, and temperature changes. Furthermore, strong and durable polyethylene has a longer lifespan. Thus, it offers value to the customer.

Check the compatibility and processing

The retailers should check the compatibility of the polyethylene. They should look for options that are compatible with various additive and filler manufacturers. This will allow them to source for customized products suitable for various applications. Furthermore, they should check the processing requirements, such as the extrusion and molding techniques. This ensures they get products that are easy and cost-effective to manufacture.

Consult experts

Buyers should consult industry experts when sourcing for polyethylene products. They can consult the suppliers' engineers or independent consultants. This will enable them to understand the technical aspects of the polyethylene products. Furthermore, it enables them to make informed decisions when sourcing.

Certifications and standards

Buyers should check the industry standards and certifications for polyethylene products. They should get products from suppliers who comply with the industry's best practices and standards. The certifications are proof of quality and can help the buyers to get high-quality products.

Q1. What is the lifespan of polyethylene?

A1. Polyethylene does not degrade quickly. Its lifespan can range from 20 to 30 years or more, depending on the type, application, and environmental conditions. Factors like exposure to UV light, temperature, and presence of chemicals can influence its longevity.

Q2. What are the disadvantages of polyethylene?

A2. While polyethylene has many advantages, it also has some disadvantages. For example, it has a lower resistance to UV radiation and high temperatures than other materials like polypropylene. This makes it less suitable for certain outdoor applications where prolonged UV exposure or high heat is a factor. Additionally, polyethylene has a higher tendency to scratch and dent than other plastic materials.

Q3. What is the difference between HDPE and PE?

A3. High-Density Polyethylene (HDPE) is a type of polyethylene with a density of 0.941 to 0.965 g/cm3. It is manufactured using less branching than other types of polyethylene, making it stiffer and stronger. Other types of polyethylene include Low-Density Polyethylene (LDPE) and Linear Low-Density Polyethylene (LLDPE).