(1992 products available)

Plastic bags 20x30 come in diverse types because each type fulfills specific requirements and purposes. These include simple storage, organizing, or protecting delicate products. Below is a breakdown of the major categories.

Flat plastic bags

A flat plastic bag in the stated dimensions is primarily used for storing goods and keeping items arranged. Such bags are generally made from low-density polyethylene (LDPE) or polypropylene and feature a bottom seal and no gusset. Their uncomplicated shape makes them ideal for straightforward packaging applications. The bags are crystal clear, making what is packed in them visible, and are often deployed for purposes like packaging clothes, documents, and small items. A 20x30 plastic bag of the flat variety can be modified to include printing for branding and other decorative purposes, as well as for providing additional thickness for improved durability.

Ziplock plastic bags

The ziplock plastic bags are unique and reusable. They feature a ziplock or resealable top made out of polyethylene (PE) or nylon. Their 20x30 sizes make them ideal for organizing small items since they can keep such items separate. They are widely applicable in food storage, crafting, and for the protection of small hardware items. A notable advantage of these bags is that they allow for easy removal of air and can be opened and closed multiple times, hence their popularity for storage that entails multiple accesses.

Gusset plastic bags

Gusset plastic bags differ from flat bags in that they have expandable sides (gussets). This permits a larger opening and greater capacity. In the 20x30 size variant, they are typically made from polyethylene or polypropylene. Gusseted bags are suited for holding bulkier items since they stand on their own when filled. Common uses are in packaging foods, such as baked goods, and other products that require more space than standard flat bags can provide. The gussets also enable the bags to be compressed for convenient storage when not in use.

Heavy-duty plastic bags

These 20x30 heavy-duty plastic bags are stronger and thicker than standard flat bags. They are constructed from premium-grade LDPE. The enhanced durability makes them ideal for environments that demand increased protective packaging. Common uses include sorting and transporting large hardware items, including tools, or packing clothing for storage. Additionally, these bags act as protective covers against dust and moisture in scenarios where items will be left unused for an extended period.

The design of a plastic bag 20x30 entails more than just preparation for packaging; it also involves aesthetic and functional considerations that enhance the bag's ability to serve certain purposes and afford an appealing look. Below are the major designs.

Solid color plastic bags

The designs in solid color plastic bags are basic but still influential in setting a desired perception. These bags come in a vast array of colors. Each hue is selected according to the utility or emotional impact intended. For instance, bags in blue may signify calm and be typically employed in the packaging of items for storage or use in giveaways at marketing events. In retail stores, red and black are associated with the phenomenon of heat and elegance and, hence, are used by some merchants as reusable shopping bags. opacifying the contents within may not always be necessary, depending on the particular purpose of these bags, such as hiding the contents or, in some cases, simply for decoration.

Printed plastic bags

Plastic bags of this size are typically printed with varying designs, including logos, patterns, and messages. Such printed designs are widely used in marketing applications, where the bags act as mediums for brand promotion. Common printing techniques include flexography and lithography, which let vibrant and full-color graphics appear on the plastic. This design type makes the bag serve two purposes as a packaging product and an advertising medium for the company. Various artistic and commercial endeavors, including craft supplies and artwork for exhibits, use these bags.

Custom plastic bags

Custom plastic bags offer an extensive range of design and functionality options. Customization options include printing exclusive artwork or logos, adjusting handles, adding special closures, and changing thickness and types of plastic. Businesses often pick a custom bag design to facilitate their purpose of being distinct or to fulfill specific packaging needs. Events such as galas, celebrations, and conferences also frequently utilize these bags as gifts to create a unique experience for the recipients.

Patterned plastic bags

Those available in 20x30 size with patterned designs that include florals, geometric figures, and seasonal themes provide aesthetic value and enhance the purpose of the bag. Production of such bags is mainly meant for events like weddings, birthday parties, and holidays, as in such cases the demand is for more decorative and cheerful bags. Patterns can also assist in obfuscating the product within the bag that requires discretion but is not as effective as that achieved through opaque bags.

The materials used for a 20x30 plastic bag are fundamental in ascertaining the bag's purpose and functionality. Therefore, each material possesses unique attributes that make it most suited for specific uses. Below are the details.

Low-density polyethylene (LDPE)

LDPE is often the plastic of choice for the production of 20x30 bags. It is malleable and resilient. The properties of LDPE make it possible to fabricate plastic bags that are thick enough to resist breaking yet pliable in such a way as to tightly fit over delicate items. Furthermore, LDPE is resistant to chemicals, which means its applications in grocery bags, garbage bags, and wet storage are effective. Another benefit of LDPE is that it is thermoplastic and recyclable. Hence, this material supports sustainable practices.

Polypropylene (PP)

Polypropylene is formed into bags that are more transparent and rigid. Due to these characteristics, PP is especially suitable for use where clarity of vision is needed, as in the packaging of retail merchandise. Moreover, this material is heat-resistant, thus making it appropriate for applications that might subject it to higher temperatures, including microwavable food containers. Bags made from polypropylene are perceived as neater, with a polished feel that is more suited to promotional or upscale retail environments. In addition, its robust nature also gives it the ability to be effective in the packaging of products that require greater protection.

High-density polyethylene (HDPE)

HDPE plastic bags are thick in gauge and possess great tensile strength. These features make it ideal for heavy-duty uses. In particular, grocery bags and construction waste bags often employ this material due to its rugged and economical qualities. In addition, the seams in these bags are offers enhanced support, which is particularly useful when carrying items that are heavy or have sharp edges. Another benefit of HDPE is its ability to be recycled. This material lessens its environmental impacts and allows it to be used in many applications.

Linear low-density polyethylene (LLDPE)

Linear low-density polyethylene (LLDPE) is used to make a flexible, resilient plastic bag. Its unique polymer structure endows it with remarkable strength and elongation ability. The adaptability of these bags makes them suitable to retain their shapes even when the contents shift or are filled. They offer exceptional puncture resistance, making a bag that is suitable for packing fragile or irregularly shaped items. LLDPE is a popular material in the making of shipping bags, textile covers, and general-purpose utility bags due to its numerous advantages.

There are several considerations that business owners should keep in mind when purchasing plastic bags from Cooig.com. Below are the key considerations.

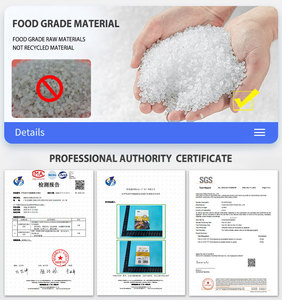

Material composition

Business owners should ensure that the plastic bags they purchase have been made using premium-quality material. The material used for making the bags should be durable and flexible to ensure that it can carry items without ripping off or stretching out.

Customization options

Depending on the buyer's preferences and needs, plastic bags can be customized in different ways. They can be printed with various designs, texts, or logos to represent a certain brand. Additionally, buyers can request bags with unique finishes, such as glossy or matte, as well as different materials or combinations to ensure that the bags are eco-friendly.

Quantity and size

Another key factor that business owners need to know is the assortment of bag sizes and sorts they offer. Business owners need to ensure that the plastic 20x30 bags they settle for have been manufactured in various materials, for instance, flat, gusseted, and zipper plastic bags. Moreover, depending on different customers' needs, plastic bags can be ordered in various quantities, from small daily needs to large purchases.

Usability and application

Business owners should analyze how their target consumers are likely to use these bags. The plastic bag's versatility for packaging food products, garments, and nonphysical products like in shipping should be assessed. Buying plastic bags suitable for different occasions, like daily use or special events, will benefit retailers.

Handle options

In case the buyers get bags that are going to be carried implements, they should consider the types of handles that are available. Some of the available options include no handles at all, or they could have punched out handles or soft carrying straps. All these options elevate the plastic bag's portability and practicality.

Evaluating costs and budgets

Ultimately, the material and manufacturing costs of the plastic bags will impact the overall costs. To enable a retailer to get the best bargain, they should conduct due diligence and quote various manufacturers. Just like other plastic products, they should also consider the management costs likely to be associated with them. For instance, by considering the payment of various placards and possibly the costs of insuring them, they should work with affordable plastic bags to ensure their business is invariably profitable.

Plastic bags in the given dimensions are not bags for shipping in the normal sense but are often used as inner pack bags in shipping. Packing materials such as bubble wrap or packing peanuts usually accompany these bags to protect them during transit, especially in fragile items.

Yes, these plastic bags are customizable. They can be printed with various texts, messages, designs, or even logos for a certain brand. They can also be made in different materials with various finishes, like matte or glossy, which are highly sought after by retailers and brands to ensure the bags represent a certain brand.

Some of the 20x30 plastic bags are manufactured with handles. Such bags are commonly used in retail settings, where customers need a bag that can easily be grabbed and carried. In those that do not include a handle, a punched-out handle can be used to help carry a physically heavier bag.

Most of today's plastic bags have been made through processes that can be environmentally-friendly. Some of them can be made from recyclable materials such as polyethylene. Moreover, many manufacturers recycle their customers' old plastic bags.

The thickness or gauge of these plastic bags widely varies depending on their intended usage. Common thicknesses for general packing or storage use are 1 mil or 2 mil. For industrial or heavy-duty applications, thicker plastics, such as 4 mil or even more, are often used.