(159374 products available)

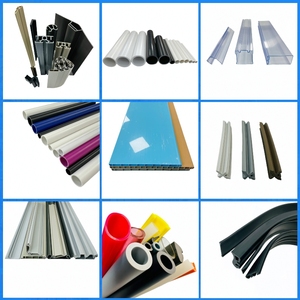

PE, PP, ABS, and PVC are materials frequently used in plastic manufacturing. Each of them has unique characteristics and applications. Here are the different types of plastics and their classifications:

Low-Density Polyethylene (LDPE)

Linear Low-Density Polyethylene (LLDPE)

High-Density Polyethylene (HDPE)

High-Pressure Polyethylene

Homopolymer Polypropylene (PPH)

Random Copolymer Polypropylene (PPR)

Block Copolymer Polypropylene (PBC)

General Purpose ABS

High-Impact ABS

Heat-Resistant ABS

Flame-Retardant ABS

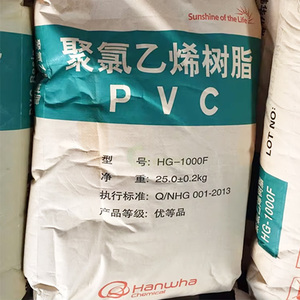

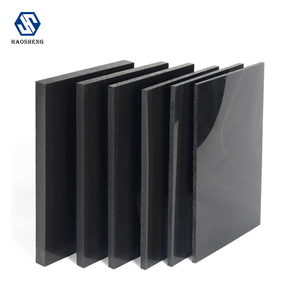

Rigid PVC (uPVC)

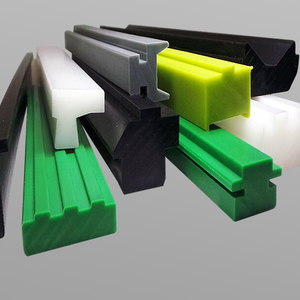

Flexible PVC

Electrical Enclosures:

ABS plastic is popularly used in making electrical enclosures. These are boxes that house electrical components. They protect the wires and other electrical parts from moisture, dust, and impact. ABS is used because it has a low electrical conductivity. This means it can prevent electricity from flowing through it. ABS plastics are also strong and durable. They ensure the electrical enclosures can last long and won't break easily.

Safety Helmets:

PVC is sometimes used to make safety helmets. These are headgears that workers wear in places like construction sites. PVC helps ensure safety by making helmets that won't break when hit by an object. They are also lightweight, which means workers won't feel heavy when wearing them. PVC helmets are also waterproof. This means they can be used in different weather conditions without getting damaged.

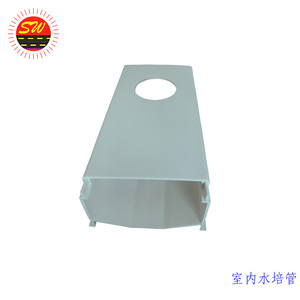

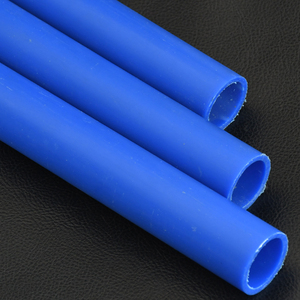

PVC Ducts:

PVC is also used to make ducts for HVAC (Heating, Ventilation, and Air Conditioning) systems. These ducts allow air to circulate in buildings and keep rooms warm or cool. The circulation is done without much noise or interruption. This is because PVC is smooth on the inside and allows air to pass freely. PVC ducts are also durable and resistant to moisture. They won't get mold or mildew, which keeps the ducts clean and healthy.

Hospital Containers:

PE or polypropylene plastics are often used to make medical containers. These are boxes or bags used to store medical waste or transport organs for surgery. Polypropylene is popular because it is lightweight. This makes containers easy to move around. They are also stackable, which helps save space in hospitals. PE and polypropylene containers are also strong. They won't tear or break when transporting or storing items.

Labware:

PE and polypropylene plastics are used to make beakers, test tubes, and petri dishes. These lab items are popular because they are transparent. This means scientists can see the liquids or samples inside. They are also shatterproof. This means they won't break into pieces if dropped, which helps keep users safe from injuries.

Assessing the Application Requirements

Consider the project needs. Look at things like how strong, flexible, and heat-resistant the final product needs to be. Different plastics handle stress, temperature changes, and impacts in their own ways. Some hard or bendable plastics work better for certain jobs than others. If the last thing has to put up with high heat or strong forces, pick materials that can take that. Match the application to the plastic qualities.

Evaluating Cost and Budget Constraints

Watch the costs. Some plastics are cheaper than others. Consider the budget for the whole project. Using less expensive plastics like PP or PE can lower costs upfront. But also think about how long the final product will last and its quality. Spending more on a plastic with better qualities may save money later if it works better for what needs to be made.

Considering Environmental Impact

Most companies today pay attention to how their work affects the planet. When picking a plastic, think about how it can be recycled when its time is up. Some, like ABS, have recycling programs. Others, like PVC, are made from things that can be reused. Consider the whole life cycle of the plastic from production to disposal. Choosing plastics with lower environmental footprints matches modern values.

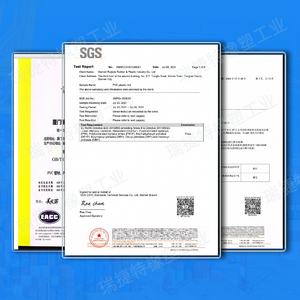

Reviewing Regulatory and Industry Standards

Certain fields have rules about materials used. The medical field, food packaging, and construction all have standards for specific plastics. Those rules are there to keep people safe. Before settling on a plastic, check to see if it meets any industry guidelines for the application. Using a plastic approved for the job helps avoid legal problems down the road.

Examining Aesthetic and Design Flexibility

Things like color, texture, and shape matter as much as function. Some plastics come in many colors and finishes, while others have set looks. Think about how the plastic will be formed, too. Some allow for more complex designs, like curved surfaces or textured grips. If appearance and design flexibility matter, pick a plastic that can be customized to fit those visual goals.

Q1: How recyclable are PE, PP, ABS, and PVC plastics?

A1: PE and PP are highly recyclable, with products like plastic bags and containers branded to indicate the recycling code. ABS and PVC are also recyclable, but the process is more complex. ABS is often recycled through mechanical means to create new ABS products. PVC can be recycled repeatedly without degrading its properties, and post-consumer PVC waste is often collected and converted into new pipe through the vinyl cycle.

Q2: Which plastic is better for creating durable products?

A2: Plastics like ABS and PVC offer enhanced durability. ABS provides impact resistance and toughness, making it suitable for products like helmets, toys, and durable casings. PVC is a good choice for long-lasting applications, particularly in construction. Its strength, weather resistance, and ability to withstand repeated bending make it an excellent choice for pipes, windows, and doors. PE and PP are suitable for everyday use containers, flexible packaging, and products that don't require high impact resistance.

Q3: What are the key factors to consider when selecting a plastic for a specific application?

A3: Consider the mechanical properties of the plastics, such as impact resistance, tensile strength, and durability. Evaluate the environmental conditions, such as exposure to UV light, temperature extremes, and moisture. Consider the product's lifecycle, including manufacturing, disposal, and recycling. This helps to choose a plastic that aligns with sustainability goals. Consider the regulatory requirements relevant to the application, particularly for medical and food-grade products.