(4759 products available)

Steel grating is a popular choice for walkways, stair treads, and platforms because of its lightweight, strong, non-slip surface, and ability to withstand heavy loads and harsh environments. They are used in many industries, including chemical processing, oil and gas, power generation, construction, and infrastructure. They come in several types, including:

Painted steel grating: This is a type of steel grating that has undergone surface preparation and coating to enhance its protection against corrosion. The process involves cleaning the steel to remove any dirt, grease, or rust using a chemical solvent or by sandblasting. This is followed by applying a liquid paint by electrostatic spray or manual spray. The paint is cured in an oven at a certain temperature, depending on the type of paint used. The finished product has a textured or smooth surface, depending on the buyer's specifications. It comes in various sizes and shapes. The advantages of this type of grating include the following: it is lightweight, has high strength, is durable, and has a non-slip surface.

Painted catwalk grating: This is an expanded metal product designed specifically for use as a walking surface. It is light and slip-resistant, allowing pedestrians to walk safely. It is also called walkway grating or catwalk grating. It is made from carbon steel, aluminum, or fiberglass. It is made through a process known as shearing and stretching. The process involves cutting the metal sheet with a shear and then stretching it using a single or double stretching machine. The metal can then be painted or powder-coated to prevent rusting and improve its appearance. Its applications include: walkways in factories, outdoor walkways, and catwalks in industrial settings.

Welded steel grating: This is a type of industrial steel grating that consists of load and cross rods. The load rods are the primary support rods running parallel to the walkway. At the same time, the cross rods provide transverse support and are welded to the load rods at regular intervals. The production process involves cutting the steel rods to the desired length and arranging them into a grid pattern. The load and cross rods are then welded together using an electric resistance welding machine. After welding, the steel grating is usually hot-dip galvanized to prevent rusting. Applications of this type of steel grating include stair treads, platforms, and walkways in industrial settings.

Steel grating offers a variety of features that make it a popular choice among engineers and architects. These features include:

Painted steel grating is widely used across different industries and applications due to its strength, durability, and slip resistance. Here are some common usage scenarios:

Walkways and Pedestrian Bridges

Steel grating is commonly used in walkways and pedestrian bridges in public parks, commercial areas, and urban environments. They allow natural light and air flow while providing a safe walking surface.

Industrial Flooring

Steel grating is widely used on industrial floors in factories, power plants, and chemical facilities. They can withstand heavy foot traffic and machinery while allowing the passage of light and air. This makes them ideal for use in industrial environments.

Platform and Catwalks

Painted steel grating is used in platforms and catwalks in industrial plants, warehouses, and storage units. They provide a safe walking surface and allow workers to monitor processes and equipment.

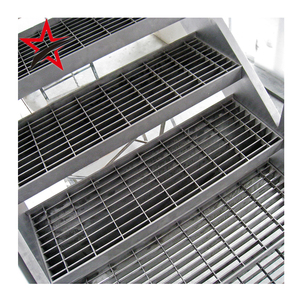

Stair Treads

Steel grating treads are used in high-traffic areas such as staircases in buildings, stadiums, and public spaces. Their textured surface provides excellent traction, reducing the risk of slips and falls.

Parking Lots and Garages

Steel grating is used in parking lots and garages to create ramps, driveways, and parking spaces. Their strength and durability can withstand the weight of vehicles and heavy traffic. Additionally, their open design allows water runoff, reducing the risk of flooding and water damage.

Drain Covers and Grates

Painted steel grating is used as drain covers and grates in outdoor areas, parking lots, and driveways. They provide a safe surface for vehicles and pedestrians while allowing water to pass through and prevent flooding.

Machine Guards

Steel grating is used as machine guards in factories and industrial plants. They protect workers from moving parts and machinery while allowing visibility and ventilation.

Exterior Walkways

Exterior walkways in commercial and residential buildings use steel grating to create a durable and low-maintenance surface. Their open design reduces the accumulation of snow, ice, and debris, making them safer in winter.

Roof Decks

Steel grating is used as roof decking in buildings to provide structural support and ventilation. Their lightweight and strong design makes them ideal for use in roof construction.

Load-bearing capacity

First, check how much weight the painted steel grates can carry. Each type of grate has a different load capacity. Choose one that can support the intended walkways or platforms without bending or breaking. Heavier loads need stronger grates.

Gap width

The space between bars affects safety. Wider gaps are riskier, so check local codes for guidance on acceptable gap widths. Find a good balance between gap width for drainage and slip prevention.

Slip resistance

Consider where the grates will go - inside or outside. Non-slip surfaces are important for outdoor areas exposed to rain or snow. This prevents dangerous slips and falls on painted steel grating with smooth surfaces.

Corrosion resistance

Think about the environment around the grates. Will they be near saltwater, chemicals, or just air? Grating coated with galvanized paint or powder is best for areas with moisture or chemicals. The coatings protect against rust longer than uncoated grates.

Aesthetics

Appearance matters if the grates are visible, like in patios or decks. Choose colors and styles that match the overall look. Grates with different patterns offer function and visual appeal.

Ease of installation

Check how the grates attach - welded, bolted, or clipped. Some connect methods are easier than others. Clipped grates may work better for DIY projects than welded or bolted options that require special skills. Consider the installation method's complexity and cost.

Upkeep requirements

All grates need maintenance to last. Welded and bolted types may need more frequent reviews than clipped grates since they are permanent connections. Consider the long-term cleaning and repair needs to choose a low-upkeep option.

Q: What are the benefits of painted steel grating?

A: The advantages of steel grating include good light and air transmission, high load-bearing capacity, anti-slip surface, and lightweight. It is also durable and strong, making it suitable for heavy-duty applications.

Q: What are the different types of painted steel grating?

A: There are several types of steel grating, including plain grating, serrated grating, industrial grating, and non-slip grating. It can also be categorized based on materials, such as steel, fiberglass, aluminum, and galvanized grating.

Q: How long does painted steel grating last?

A: Steel grating lasts longer than most other types of grating. It can last between 20 to 30 years. However, this depends on several factors, such as exposure to elements, maintenance, and the type of steel used.

Q: How to maintain painted steel grating?

A: Maintaining steel grating is simple. Just clean it regularly to prevent dirt and debris buildup. Use a pressure washer and mild detergent to wash away contaminants. Inspect it periodically for signs of damage or rust. And apply a protective coating when necessary.

Q: Where is steel grating used?

A: Steel grating is used in many different industries and applications. This includes walkways, industrial flooring, drainage covers, stairs, platforms, ramps, parking lots, and architectural applications. It is also used in power plants, wastewater treatment facilities, oil and gas industry, and chemical plants.