(3921 products available)

There are different types of grinders that are used extensively in industrial and residential areas. The OEM mini surface grinder is manufactured for more minor, detailed, and precision grinding applications. Generally, the surface grinders are used to grind the flat surfaces of metals, which may include trimming or levelling the surfaces.

Electromagnetic surface grinder:

An electromagnetic surface grinder grinder uses electricity and electromagnets to hold the workpiece in place while it is being ground. Because of its easy clamping and unclamping procedures, this grinder type is pretty widespread. Furthermore, it eliminates the need for fixation or refitting procedures, making surface grinding easier and more efficient. This device is safe, easier to manage, and offers a reliable holding force for various workpiece shapes and sizes, so it's suitable for use in various scenarios.

Air-controlled surface grinder:

Pneumatic surface grinders, also known as air-powered surface grinders, employ compressed air as their primary power source. Compressed air is a common source of energy in industrial settings and is renowned for its strength and durability. Air-controlled surface grinders shine brightly in demanding environments where electricity might not be a practical or safe option. Their design is robust and dependable, ready to face the challenges of heavy use day in and day out. It is strong enough to overcome any job's difficulty and precise enough to accomplish professional results.

Bench top surface grinder:

A bench surface grinder is a machine tool that is used to grind or hone the surfaces of small parts. The surface grinders work by using an electric motor to drive a spinning grinding wheel that removes small amounts of material from the surfaces being worked on. Some machines may also use coolant or other lubricants to aid in the grinding process and improve surface quality. A mini bench top surface grinder has the same specifications and features as a regular bench grinder but is smaller in size. This allows for easy storage and portability of the machines.

Handheld surface grinders:

Portable surface grinders are handheld devices that are easy to control and operate. They have comfortable grips that allow easy handling and use. Moreover, the grinder is used to smoothen rough and uneven surfaces, remove paint or any coating on the surface, and polish and smoothen welds. Generally, cement handheld surface grinders are used to even out and smoothen other cement products and materials, such as the ground, walls, and tiles.

Specifications for mini surface grinding machines include factors like the power of the motor, the size of the work table, and the voltage.

The main parts that need maintaining on a mini surface grinder are the bearings, slides, cleaning process, belts, and grinding wheel.

Machine shops:

A standard one in the machining area is the mounting of the grinder itself, usually resulting in a workstation for parts that need to be smoothed or finished. That said, bench grinders will be used for various materials, including plastic, metal, and ceramic, to shave down surfaces, create sharp edges, remove rust, and smooth out imperfections. When putting the mini grinder to use, safety is paramount; thus, wearing safety glasses, earmuffs, and, sometimes, a respirator is an easy, efficient way to prevent injuries.

Jewelry manufacturing:

The tool will also apply in jewelry making by adding a polishing wheel, compound, and buff. It's usually used on gold, silver, and platinum jewelry pieces to eliminate surface scratches after stones have been removed, remove blemishes, and blur detailing lines.

Metal fabrication:

Involved in metal fabrication, it will be helpful in operations like shaping and sharpening cutting tools, brake blades, and shears and removing burrs from the edges of metal pieces. Mini surface grinders with faster wheels will be preferred choices for optimal results.

Woodworking:

Whether restoring vintage or new pieces, bench surface grinders are easy tools to whip into action when removing paint, polishing furniture, and removing any sort of imperfection.

Construction:

Construction industry carpenters and contractors will rely on surface grinders to remove paints, varnishes, and poly coatings when refinishing wooden flooring and furniture.

Safety:

Safety is paramount when using surface grinders. They should ideally have an emergency stop button, safety guards, and other integral features. Safety guards shield operators from moving parts while protecting the equipment from potential damage. The emergency stop button allows the operator to stop the machine immediately in case of emergencies. Surface grinders for sale should have these safety features and more to keep the operator safe.

Power source and voltage:

A surface grinder's power, voltage, and horsepower impact its runtime, performance, and suitability for specific tasks. An electric surface grinder generally has a power range of 1.5-5kW. Machines with more power perform better and have higher productivity. It also has more horsepower to handle large and tough jobs. Workpieces with large dimensions usually require more power and horsepower to surface grind effectively. The voltage determines the tool's power delivery, with higher voltages supplying more power for demanding tasks. Most surface grinders use 220-240v, and international voltage standards are 110-120v or 220-240v.

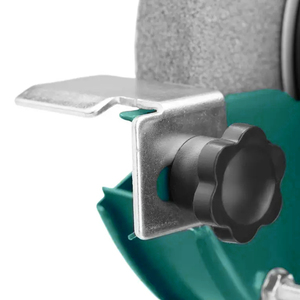

Mobility:

The weight of a surface grinder may pose a challenge for transportation, especially if surface grinding is to be done in various locations. Surface grinder manufacturers understand the importance of mobility. Some surface grinders are designed with locking caster wheels that can be easily maneuvered and locked in to secure a position when not in use. If they are frequently moved around, having caster wheels or a similar feature makes the job easier.

Attachments and accessories:

Attachments and accessories available for a surface grinder add versatility. Some mini grinders can have a band saw or electric disc saw attached to them for metal cutting applications. Other accessories like magnetic vices, chuck plates, coolant pumps, operating lamps, and dust collection systems allow operators to achieve precise results every time. When choosing a surface grinder, consider the available attachments and accessories for added versatility.

Q1: What is the purpose of a surface grinder?

A1: Surface grinders are used to produce a flat surface on metal workpieces. They are capable of creating precise, smooth surfaces and are commonly used to prepare metal slabs for welding, flattening metal surfaces for improved contact, and creating surfaces perpendicular or parallel to a specified axis.

Q2: What are the limitations of a surface grinder?

A2: Surface grinders cannot create internal cavities or spherical surfaces. They are only suitable for flat surfaces with a defined axis. Furthermore, surface grinders are not applicable to non-metallic materials, such as plastics or wood.

Q3: Can surface grinding be done without coolant?

A3: Some materials can be ground dry, but using coolant is preferable for surface grinding. The coolant helps to remove chips, prevent overheating, and prolong the life of the grinding wheel.

Q4: What machine is used to smooth concrete surfaces?

A4: A concrete surface grinder is used to smooth concrete surfaces. A mini grinder surface machine is used for concrete repair or refinishing in confined spaces or limited access areas.