(507 products available)

The OBD II type is a standardized diagnostics system used in vehicles for emissions control and diagnostics. It has been implemented in all cars and light trucks since 1996. The OBD II system monitors the performance of the engine, transmission, and major components to ensure they operate efficiently and meet emissions regulations. It provides real-time data, diagnostic trouble codes, and access to the vehicle's health and performance. The OBD II connector is usually located under the dashboard, allowing mechanics and technicians to easily connect scan tools for diagnostics. With OBD II, users can get detailed information about the vehicle's status, making troubleshooting and diagnostics easier and more accurate.

The OBD II system has different types, each with unique features and functions. The following are some common types of OBD II:

In addition to these common types of OBD II, there are other less common types, such as CAN (Controller Area Network), which is a more advanced and widely used communication protocol in modern vehicles. The OBD II type supports different communication protocols and standards, enabling various vehicle diagnostics and programming tools.

There are various specifications of the OBD II types that people should know about to understand the differences and know what suits their needs. Here are some of the OBD II types and their specifications.

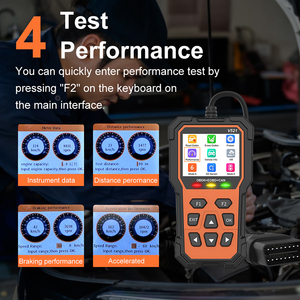

Scanner Tool

It is a handheld device used to connect to the vehicle's OBD II port. The scanning tool reads and interprets diagnostic trouble codes. Besides that, it accesses the vehicle's real-time data and sometimes downloads software updates. The scanner tool comes in various sizes, including small, medium, and large. Also, it has different display capabilities, such as LCD and color displays.

Code Reader

It is a small device that connects to the OBD II port and reads diagnostic codes. The code reader can display codes and sometimes erase them. In addition, it can access limited live data. The code reader comes in different sizes and display types.

Vehicle Communication Interface

This is a device that connects to the vehicle's OBD II port and communicates with an external computer or diagnostic server. It enables advanced diagnostic functions and software updates. The interface has a wide range of communication protocols and is compatible with various vehicles. It also enables data transfer between the vehicle and an external computer.

Adapter Cable

This is a cable that connects the OBD II port to a diagnostic tool or computer. It converts the vehicle's communication protocols to be compatible with external devices. The adapter cable has various lengths and is designed for specific vehicle models and diagnostic tools.

These are some specifications of the OBD II type. However, the maintenance process might be a bit different depending on the type. Below is the general OBD II type maintenance process.

It is that simple to maintain the OBD II type.

Choosing the right OBD II type for a business needs involves understanding the business's specific requirements and considering several key factors:

Choosing the right OBD II type is essential for an effective business. Take the time to evaluate the options, compare features, and select the one that best fits the requirements. An appropriate OBD II device can enhance productivity, accuracy, and efficiency in diagnostics and vehicle management.

It is simple to install an OBD II scanner. The only DIY required is during the actual installation of the scanner. Follow the steps below to install an OBD II scanner.

1. Find the car's OBD II port. The port is on the driver's side, under the steering wheel. The port is around the steering column.

2. Plug the scanner's connector into the OBD II port. Ensure the tabs on the connector line up with the grooves on the port.

3. Turn on the vehicle's ignition to the "On" position without starting the engine. This powers up the scanner.

4. Follow the instructions on the scanner's screen or app. Set up the date, time, and other preferences as required.

5. For Bluetooth-enabled scanners, pair it with the mobile device. Follow the instructions for connecting and configuring the scanner.

6. Launch the scanning software and select the vehicle's make, model, and year to start scanning.

7. Select the "Diagnostic" or "Read Codes" menu to check for error codes. The scanner will communicate with the vehicle's computer and display any stored trouble codes.

8. Select the "Live Data" menu to view real-time data from the vehicle's sensors and systems. This data helps in understanding the vehicle's performance.

9. Select the "Freeze Frame" menu to view the data snapshot taken when a trouble code was triggered. This helps in diagnosing issues based on historical data.

10. Select the "Clear Codes" menu to erase stored trouble codes and reset the check engine light if necessary. Only do this after addressing the underlying issue.

11. Disconnect the scanner and OBD II port. Turn off the vehicle's ignition to power down the scanner.

12. For Bluetooth scanners, delete the pairing from the mobile device to disconnect.

Q: What does OBD II stand for?

A: OBD II stands for ""On-Board Diagnostics"" version 2. It is a standardized system used in vehicles to monitor and control the performance of the engine and emissions system.

Q: How does an OBD II scanner work?

A: An OBD II scanner plugs into the OBD II port of a vehicle and communicates with its onboard computer. It can read and interpret diagnostic trouble codes (DTCs), access live data streams, and perform various tests to diagnose and troubleshoot issues.

Q: What are the different types of OBD II scanners?

A: There are several types of OBD II scanners, including:

Q: Can OBD II scanners be used on all vehicles?

A: OBD II scanners are designed to be used on all vehicles manufactured after 1996. However, the functionality and compatibility may vary depending on the vehicle's make and model.

Q: What is the OBD II port location?

A: The OBD II port is typically located under the driver's side dashboard, near the steering wheel. It may be slightly different depending on the vehicle's make and model.