(1001 products available)

The needle loom weft insertion device is a common instrument used for weaving difficult materials such as carpets, which use a high pile, because its structure is simple and easy to employ, and it is compatible with various auxiliary tools.

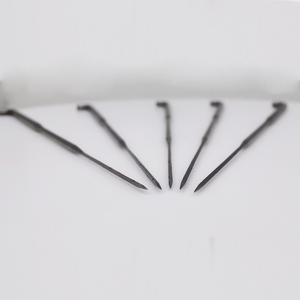

The needle loom can weave almost all types of vests by using different needle cards. The needle card has many shapes of needles, which can be used to weave products like elastic nettings, plain fabric, composite fabrics, and so on.

The selective needle loom is a type of loom that uses a selective needle weft insertion system to insert the weft yarns selectively into the shed formed by the warp ends. This needle loom works by using a particular selection mechanism to select the needles that insert the weft yarns. Among the advantages of selective needle looms, there is the possibility of inserting weft yarns at different intervals, thereby making it possible to create fabrics with different patterns and structures. Additionally, selective needle looms can use various types of weft materials, including yarns of different thicknesses and textures, further expanding the loom's fabric production capability.

Computer-controlled needle looms are generally equipped with an electronic shed formation device, a weft insertion device, and a control system. The electronic control system can be used to set the fabric pattern and design, and the loom will automatically weave according to the preset parameters. Computerized needle looms may also feature devices for automatically changing the warp and weft materials, as well as devices for monitoring and controlling weaving speed and density, among other things. These looms' versatility and automation make them suitable for the mass production of complex pattern fabrics.

The specifications of a needle loom machine for sale may vary based on the model and manufacturer. The following are the general specifications of the needle weaver.

The needle loom requires routine maintenance to keep it in good operating order and ensure it weaves warp threads efficiently. The following maintenance tips for the needle loom weaving machine will assist users in prolonging its life and reducing downtime.

The needle loom for sale is used to make various types of needle-punched fabrics, which have a wide range of applications in different industries.

Carpets

Needle looms are widely used in the carpet industry to manufacture industrial carpets and commercial carpets. Needle-punched techniques create durable, heavy piles, which are ideal for the needs of the carpet market. Therefore, needle looms can efficiently produce high-quality needle-punched carpets that fulfill commercial and industrial applications.

Geotextiles

In the engineering field, needle looms are used to make needle-punched geotextiles. This kind of textile is a versatile material. The great combination of tensile strength and durability makes it ideal for various subgrades and soil stabilization projects. Geotextiles offer functional solutions for a range of civil engineering applications.

Sound-absorbing materials

The needling machine can create non-woven sound-absorbing materials, such as acoustic panels and soundproof curtains. These materials reduce sound transmission and improve room acoustics.

Protective clothing and tarpaulins

Needle looms are used to manufacture needle-punched non-woven fabrics that serve as the raw material for protective clothing and tarpaulins. Protective clothing made of needle-punched non-woven fabrics provides effective protection in hazardous environments. Moreover, tarpaulins are made of needle-punched non-woven fabrics, which guarantees durability and weather resistance.

Automotive interiors

A few examples include acoustic insulation pads, headliners, and interior linings. Needle looms can efficiently manufacture these components, thus improving productivity in the automotive industry.

Filtration materials

Needle looms are used to produce needle-punched filtration fabrics, which are the key elements of various filtration products. Friltration fabrics show a good performance in air and liquid filtration, that is, they trap particles and contaminants, thereby ensuring the efficiency of the filtration process.

Packings

Needle looms can produce needle-punched packing materials, such as fiber tubs and sealing strips. These packing materials provide cushioning, sealing, and protection for products during storage and transportation.

Medical and hygiene products

Needle looms can produce needle-punched fiber medical products and sanitary products. For example, needling machines can make products like surgical masks, swabs, and absorbent pads, among others. The durability and reliability of these products are guaranteed by the accuracy and efficiency of the needle-punching technology.

Quality:

Needle looms for sale should be chosen based on the quality of the products that the loom produces. This is very important for businesses that are looking to expand their customer base and their overall market reach. If a needle loom cannot be used to produce quality goods, the business will most likely not have a large customer base, and its expansion efforts will come to a halt.

Production Capacity:

The production capacity of the needle loom is yet another factor that should be considered when choosing needle looms for sale. Different needle looms have different production speeds and capacities. If an investor is looking to produce a large amount of product in a small space of time, they will need to use high-speed looms with a large production capacity. Furthermore, the production capacity of the loom they are using should be in line with their end demand so that there is not too much of a deficit or surplus in production.

Ease of Use:

Needle looms for sale should also depend on how easy to use the loom is. If a business’s employees are not able to easily understand how to operate the loom, it may result in production delays and increase manufacturing costs. Choosing looms that are easy to operate and well understood by workers will streamline the production process.

Maintenance and Support:

Needle looms for sale should also be determined by the maintenance and support that suppliers offer. Equipment in the manufacturing industry tends to break down every now and then due to constant usage. When this happens, it is imperative that the supplier of the needle loom provides the buyer with the necessary maintenance guidance and support to get the machine up and running in no time. This will ensure that production is not brought to a standstill for lengthy periods of time.

Q1. What is the difference between a needle loom and a jacquard loom?

A1. A needle loom weft insertion machine uses needles to insert the filling yarns across the width of the warp yarns to create the fabric. On the other hand, a Jacquard loom controls individual threads to weave complex patterns directly into the fabric as it is made.

Q2. Do needle looms weave in both directions?

A2. Some needle looms weave the filling yarns in one direction only. However, certain types of needle looms, such as the double-needle loom, can weave the fabric in both directions simultaneously, which improves weaving efficiency and reduces production time.

Q3. Can a needle loom weave other than wove materials?

A3. One characteristic of a needle loom is its versatility. It can weave not only woven materials but also non-woven materials, such as needle-punched composites, mixtures of chemical fiber and cotton, and other fibers.

Q4. How fast does a needle loom weave?

A4. The weaving speed of a needle loom can vary depending on the type of needle loom, the material being used, the weaving density and pattern, and other factors. In general, needle looms are designed to weave at high speeds as efficiently efficiently to increase productivity.