Types of Mwm Part

Every engine needs a reliable and powerful source of energy to run. Mwm part is designed to deliver optimal performance in any heavy-duty mwm engine. It is important to know the types of mwm parts available so buyers can get the right one for their needs. Here are the different types:

-

Mwm engine parts:

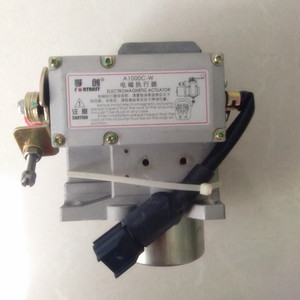

Mwm engine parts are further divided into types based on their function and construction. They include MWM cylinder heads, MWM crankshafts, MWM camshafts, MWM Cylinder blocks, MWM connecting rods, MWM pistons, MWM valve assemblies, MWM timing gear, MWM turbochargers, and MWM fuel injectors. All these parts work together to mwm engine and ensure it runs smoothly and efficiently.

-

Mwm diesel parts:

These are more specialized parts designed for use in mwm diesel engines. Just like mwm engine parts, mwm diesel parts are also categorized based on function. They include MWM fuel injectors, MWM turbochargers, MWM cranks, and MWM cylinder heads. MWM fuel injectors atomize diesel fuel into tiny particles and inject it into the combustion chamber under high pressure for optimal combustion. MWM turbochargers boost engine performance by forcing more air into the combustion chamber. MWM cranks convert the linear motion of the pistons into rotational motion. MWM cylinder heads contain the combustion chamber and house the spark plugs and valves.

-

Mwm crankshaft parts:

Mwm crankshaft parts are further divided into main bearing journals, crank pins, and throws. Mwm main bearing journals are the parts of the crankshaft that rotate inside the main bearings, supporting the crankshaft's rotation. They are usually cylindrical and smooth to reduce friction and wear. Mwm crank pins connect the crankshaft to the connecting rods, converting the crankshaft's rotation into the reciprocating motion of the pistons. They are usually located on the crankshaft's throws. MWM throws are offset sections of the crankshaft that create the reciprocating motion required to turn linear energy into rotational energy.

Specifications and Maintenance of MWM Part

MWM engines are high-performance engines known for their reliability and durability. They are used in a variety of applications, including trucks, buses, construction equipment, and agricultural machinery. Here are some common specifications of MWM engines:

- Engine type: MWM engines are typically diesel engines known for their fuel efficiency and torque.

- Displacement: The displacement of MWM engines varies depending on the model, typically ranging from 2.5 to 7.5 liters.

- Power output: The power output of MWM engines also varies depending on the model, typically ranging from 70 to 300 horsepower.

- Torque: MWM engines are known for their high torque, which is typically ranging from 200 to 800 Nm.

- Number of cylinders: MWM engines usually have 4 to 6 cylinders.

- Fuel type: MWM engines are diesel engines that use diesel fuel for combustion.

- Emissions standards: MWM engines are designed to meet modern emissions standards, including Euro 5 and Euro 6 standards.

Maintaining MWM parts is important to ensure their reliability and durability. Here are some common maintenance tips:

- Engine oil: Regularly check and change the engine oil to ensure proper lubrication and reduce wear and tear on engine parts.

- Air filter: Check and replace the air filter regularly to ensure proper airflow and prevent dust and debris from entering the engine.

- Fuel filter: Replace the fuel filter regularly to ensure proper fuel flow and prevent impurities from entering the engine.

- Cooling system: Regularly check the cooling system, including the coolant level, hoses, and thermostat, to ensure proper engine cooling.

- Timing belt: Check the timing belt regularly and replace it according to the manufacturer's recommended schedule to prevent belt failure and engine damage.

- Regular service: Take the MWM engine parts for regular service and maintenance to check and fix any problems and ensure optimal engine performance.

How to Choose MWM Part

Choosing the right MWM part for a vehicle can be daunting, and it should not be so. Here are some tips to make it easier.

- Know the vehicle: One should know the make, model, and year of the car. This will help choose the right mwm part that will suit the vehicle.

- Original vs. aftermarket: Original MWM parts are those produced by the MWM company. They are often more expensive but are of high quality and durability. MWM aftermarket parts are produced by independent manufacturers. They are cheaper, but the quality assurance cannot be guaranteed.

- Quality and warranty: ensure the MWM part chosen has a reasonable warranty period. This is a sign that the mwm part has quality and durability.

- Consider the budget: set a budget for the MWM part needed. Keep in mind that sometimes, the cheaper option might end up being more expensive because of the durability and quality.

How to DIY and Replace MWM Part

Mwm part replacement is a straightforward process, and with the right tools and knowledge, it is possible to replace them without professional assistance. Here are the general steps for replacing MWM engine parts:

- Gather Necessary Tools: Get the necessary tools mwm truck parts, such as wrenches, sockets, screwdrivers, pliers, torque wrench, and any specialized tools required for the specific part being replaced. Also, have the replacement part ready.

- Disconnect Power Source: For safety reasons, mwm engine parts may be connected to the vehicle's electrical system. Disconnect the electrical connections or batteries to avoid short circuits or electrical shocks.

- Remove the Old Part: Use the appropriate tools to remove the worn-out or damaged part gently. Follow the manufacturer's guidelines and service manual for disassembly instructions. Take note of the original part's positioning and the disassembly process, as this will help during assembly.

- Clean and Prepare: Clean the mounting surfaces and the surrounding area before installing the new MWM part. Remove any old gaskets, debris, and dirt. Preparing the mwm part replacement area ensures a proper seal and reduces the risk of contamination or damage to the new part.

- Install the New Part: Follow the manufacturer's instructions to install the new MWM part. Ensure the right alignment, positioning, and torque specifications for bolts and screws. Mwm parts catalog has detailed installation instructions.

- Reconnect Electrical and Other Connections: Once the new part is installed, reconnect any electrical connections, hoses, belts, or other components disconnected during disassembly. Ensure all connections are secure and properly fitted to prevent leaks or electrical failures.

- Test the System: Before closing the hood or the engine compartment, mwm truck owners should run a brief test to ensure everything is operating smoothly. Look for leaks, unusual noises, or error codes on the dashboard. Make sure all electrical connections and mechanical components are functioning properly.

- Dispose of Old Parts: Follow local regulations and guidelines for disposing of old parts and any materials used during the replacement process. Recycle where possible to minimize environmental impact.

Some mwm parts, such as small filters, belts, and gaskets, are easy to install. However, if in doubt, consult a professional mechanic to avoid damage to the part or the engine.

Q&A

Q1: Are MWM parts used in MWM engines only?

A1: No, MWM parts are not used in MWM engines only. MWM parts are used in MWM engines, which are known for their reliability and performance. MWM parts are also used in other engines, like Cummins and Perkins, which are also known for their reliability and performance.

Q2: Are MWM parts used in MWM engines only?

A2: No, MWM parts are not used in MWM engines only. MWM parts are used in MWM engines, which are known for their reliability and performance. MWM parts are also used in other engines, like Cummins and Perkins, which are also known for their reliability and performance.

Q3: Can MWM parts be used in engines other than those manufactured by MWM?

A3: Yes, MWM parts can be used in engines other than those manufactured by MWM. MWM parts are used in MWM engines, which are known for their reliability and performance. MWM parts are also used in other engines, like Cummins and Perkins, which are also known for their reliability and performance.

Q4: Are MWM parts compatible with other brands of diesel engines?

A4: Yes, MWM parts are compatible with other brands of diesel engines. MWM parts are used in MWM engines, which are known for their reliability and performance. MWM parts are also used in other engines, like Cummins and Perkins, which are also known for their reliability and performance.