(672 products available)

MS Grating is a hot-rolled carbon steel product with a slip-resistant surface. It is used in a variety of construction and home projects. The types of MS grating are based on the method in which the steel bars are arranged and welded. Below are the types:

Plain Grating:

This is the most basic type of MS grating. It consists of load and cross bars. The load bars are the steel bars that run parallel to the length. The cross bars are the steel bars that run perpendicular to the load bars. Both steel bars are welded together. This creates a strong and durable platform. This MS grating is often used in walkways, platforms, and drainage areas.

Pressed Grating:

Pressed MS grating has a flat surface. Its load and cross bars are pressed together using high pressure. This forms a joint without welding. The joint is called a pressure joint. It makes the grating look seamless. It is used in areas that need a smooth surface. Examples are pedestrian walkways and industrial settings.

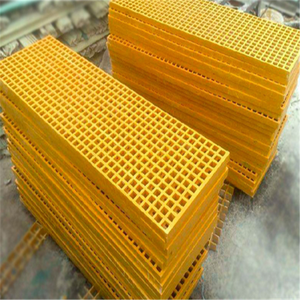

Fiberglass Reinforced Grating (FRP):

This type of grating is made from fiberglass. It is used in areas that are exposed to harsh chemicals. Examples are chemical plants and waste treatment facilities. Since it is made from fiberglass, it cannot rust. It is also very lightweight.

Heavy-Duty Grating:

This grating uses thick load bars. These load bars can withstand heavy loads and high traffic. This makes it a great option for industrial applications. Examples of industrial applications are heavy machinery areas and loading docks.

Safety Grating:

This type of grating is designed specifically for safety. It has a raised pattern on the surface. This makes it slip-resistant. It is ideal for areas where safety is important. Examples are stair treads and ramp surfaces.

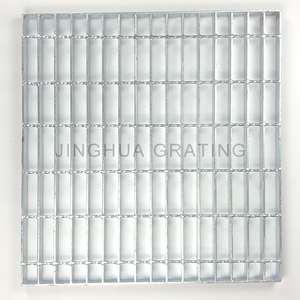

galvanized grating

This type of grating has a galvanized finish. The steel bars are coated with zinc. This coating prevents rust and corrosion. It increases the lifespan of the grating. It is perfect for outdoor and waterfront applications.

Decorative Grating:

Decorative grating is designed for aesthetics. It features intricate patterns and designs. This makes it visually appealing. It is used in architectural applications.

MS grating has different applications in various industries. It is used in platforms, walkways, and catwalks in industrial plants, factories, power plants, sewage treatment plants, oil refineries, chemical processing plants, marine environments, and more.

Additionally, it has features that make it essential in these applications. Some of the features include:

There are various applications and usage scenarios of MS grating. These include:

Walkways and Platforms

MS grating is used on walkways and platforms. This is because it provides high traction underfoot. Also, it allows the transmission of light and air. Additionally, this type of grating is used for pedestrian walkways. It is also used for platforms in industrial spaces and environments.

Heavy-Duty Floor

MS grating forms a strong, durable floor surface. It can withstand high traffic and heavy loads. This makes it ideal for use in warehouses, factories, and storage facilities.

Drainage Solutions

MS gratings are used as drain covers in drainage systems. They prevent debris from clogging drains and allow water to flow freely. They also prevent people from falling into drains.

Industrial Applications

MS grating is used in different industries, such as chemical, food, and petrochemical industries. It allows fluids and gases to pass through while providing a stable surface.

Rooftops and Ceiling

MS grating can be installed on rooftops and ceilings. It can resist harsh weather and environmental conditions. This includes UV radiation, rain, and wind. Using grating on rooftops and ceilings helps to reduce the overall weight of the structure.

Platforms and Stairs

MS grating is a good choice for stairs and platforms. It offers a non-slip surface. This makes it safer than other floor materials.

Machinery Support

MS grating provides a good solution for supporting heavy machinery. It allows for the proper drainage of fluids. Additionally, it helps to ventilate and circulate air around the machinery.

Marinas and Docks

MS grating is used at marinas and docks because it is resistant to corrosion. It allows water to flow freely and prevents algae growth.

Safety Barriers

MS grating can be transformed into safety barriers by welding the right support posts. These safety barriers are used in industrial and construction sites. They prevent workers from falling off edges and high platforms.

Load and Span Requirements

Consider the load requirements and spans. Heavier loads or longer spans may require a higher percentage of open area for structural integrity and drainage.

Safety and Traction

Evaluate safety needs. Slip-resistant surfaces are crucial in high-traffic or wet areas to ensure safety.

Durability and Corrosion Resistance

Assess environmental conditions. Choose materials with high corrosion resistance, such as galvanized or stainless steel, for grates exposed to moisture or chemicals.

Maintenance and Cleaning

Consider maintenance requirements. Select designs that facilitate easy cleaning and maintenance, especially in hygienic or industrial settings.

Aesthetic and Design Flexibility

Think about aesthetics and design flexibility. Opt for finishes and styles that complement the surroundings, and consider customizable options for unique requirements.

Installation and Cost

Evaluate installation processes and costs. Simple designs may reduce installation time and costs, while complex options might offer enhanced features but require more resources.

Environmental Considerations

Examine sustainability and environmental factors. Recycled materials and sustainable manufacturing practices are essential for environmentally conscious projects.

Regulatory Compliance

Ensure compliance with industry standards and regulations. Consult with experts to guarantee that the selected grating meets all legal requirements for safety and performance.

Q1: What is the difference between welded and swaged ms grating?

A1: Welded ms grating has a solid, one-piece look. The cross bars are welded to the bearing bars, making it super strong. A swaged ms grating has a different style. The cross bars are swaged (squeezed) into the bearing bars, so they slot inside. This makes the top surface smooth and gives the grating a lighter appearance.

Q2: How to clean and maintain ms steel grating?

A2: Cleaning ms grating is simple. Just sweep or blow off dirt and debris. If there are tough stains, hose them off with water or use a power washer. For maintenance, check the grating is still securely attached. Tighten any loose bolts or screws when needed.

Q3: Is installation of ms steel grating difficult?

A3: Not at all. Installing ms grating is easy, like putting together a metal floor. Just place the grating panels side by side and use bolts or clamps to connect them. Make sure to evenly space the bearing bars for a sturdy fit.

Q4: Can ms grating be painted different colors?

A4: Yes, ms steel grating can be painted in different colors. To prevent rust and add color, paint the grating with exterior metal paint in the desired shade. This helps the grating blend into surroundings or stand out.

Q5: How long will ms steel grating last?

A5: With proper care, ms grating can last for decades. It is durable and tough. Just make sure to periodically clean it and check that all the bolts are tight. This helps prevent any issues and maximizes its lifespan.