Understanding Motor RPM: An Introduction

Motor RPM, or Revolutions Per Minute, is a critical measurement in the functionality and performance of electric motors and engines. It indicates how many times the motor completes a full rotation in one minute. This specification is crucial for a variety of applications, from household appliances to industrial machinery. Understanding the significance of motor RPM can enhance efficiency, optimize performance, and inform better decision-making when purchasing or operating motor-driven equipment.

Types of Motor RPM

Motor RPM can be categorized into a variety of relevant types based primarily on their construction and application. Understanding these types is essential for choosing the right motor for your needs:

- Direct Current (DC) Motors: These motors typically provide a consistent RPM that can be easily controlled with voltage adjustments.

- Alternating Current (AC) Motors: The RPM of AC motors is frequency-dependent and well-suited for heavy-duty applications.

- Stepper Motors: Designed for precise control, stepper motors offer predictable RPM settings, ideal for robotics and automation tasks.

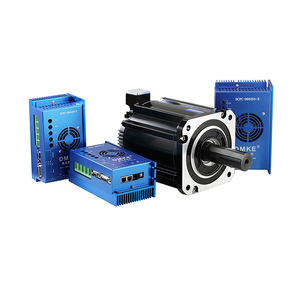

- Servo Motors: Known for their high-torque and adjustable RPM capabilities, servo motors excel in applications requiring precise motion control.

Applications of Motor RPM

Motor RPM plays a pivotal role across various sectors, including:

- Industrial Manufacturing: High-speed motors facilitate the operation of conveyor belts, pumps, and other machinery that need to maintain a specific speed for optimal production efficiency.

- Automotive Engineering: Engine RPM is essential for assessing vehicle performance, fuel efficiency, and emission controls.

- Home Appliances: Motors in devices like washing machines and HVAC units depend on accurate RPM settings for effective functionality.

- Aerospace Technology: Precision is key; motor RPM governs the speed of various mechanical parts in aircraft and drones.

Features and Advantages of Understanding Motor RPM

Grasping the significance of motor RPM offers numerous advantages that can elevate operational effectiveness:

- Efficiency Improvement: By selecting motors with the appropriate RPM for specific applications, energy consumption can be significantly reduced.

- Performance Optimization: Understanding the required RPM allows for the selection of motors that will sustain optimal performance under various conditions.

- Cost-Effectiveness: Better RPM knowledge can lead to smarter purchases, saving costs on unnecessary power and reducing maintenance issues.

- Enhanced Control: Motors with adjustable RPM settings provide flexibility, enabling users to modify motor speed according to changing operational needs.