(21588 products available)

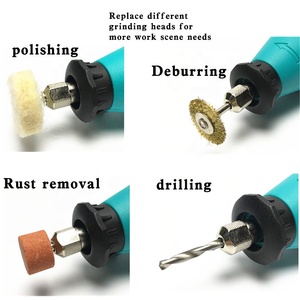

A mini tool grinder is a power tool for grinding metal surfaces. It can also be used for various tasks such as cutting, cleaning, sharpening, and polishing multiple materials, including metal, marble, glass, wood, and jewelry. There are many types of mini tool grinders.

Electric mini tool grinders

The most common type of grinder is the electric one, powered by electricity. It has a motor that drives the spindle, which holds the grinding wheel. Electric grinders come in various sizes, wattages, and spindle measurements. Usually, the spindle speed of electric grinders is 220 volts and 3000-12000 RPM or higher. Electric grinders are simple, practical, and easy to use. They are suitable for light work. However, the power source limits them.

Pneumatic mini tool grinders

Pneumatic grinders are powered by compressed air. They require an air compressor for operating. Pneumatic mini grinders stand out due to their lightweight construction, simplicity, and compactness. They deliver high-speed rotation and offer more spindle speed than electric mini grinders. A common speed for pneumatic grinders is about 70,000 to 90,000 RPM. Some models even have a speed of up to 300,000 RPM. These features make them suitable for heavy work. However, air pressure controls them, so they are not suitable for all applications.

Battery-operated mini tool grinders

The development of lithium-ion battery technology makes it possible to manufacture battery-operated mini grinders, which are also referred to as cordless grinders. These grinders have more comfortable operation and portability options than electric and pneumatic grinders because they do not require an electric cable or air hose to function. Battery-operated mini tool grinders are suitable for minor repairs, polishing, or burr removal; their flexibility makes them ideal for hard-to-reach places and outdoor jobs.

Straight mini tool grinders

Straight grinders have a straight body design and offer precise control and maneuverability. They are commonly used for grinding, polishing, and buffing tasks. Straight grinders are suitable for intricate work, tight spaces, and detailed shaping.

Die mini tool grinders

Die grinders are small, lightweight tools designed for heavy-duty work and high spindle speeds. They can be used to grind metal welds and burrs, sharpen chisels, refine threads, clean metals, and cut threads. They are much more powerful than mini grinders. Die grinders are suitable for professional applications that require intense grinding and high durability.

The specifications of a mini grinders highlight the unique features that differentiate them from other models. The key specifications include the power, speed, and disc diameter.

Maintaining the mini grinders is easy. The most important maintenance task is changing the grinding wheel or disc. While changing the disc, users have to ensure that the newly installed disc does not exceed the maximum diameter mentioned on the tool. Also, they should choose the right grinding wheel for the specific task.

Like all power tools, mini tool grinders also require cleaning. Users should clean the power tool’s housing and air vents regularly to remove any dust or debris buildup. Compressed air can also be used to clean the vents carefully. The tool should be lubricated periodically, including the bearings and moving parts. It minimizes wear and tear and ensures smooth operation. Users should check the cord and plug of corded mini grinders regularly. Any sign of damage or wear should be addressed immediately. For safety purposes, they should never use the grinder with a damaged power cord.

Mini tool grinders are handy tools for many industries where polishing and sharpening are required. Their usefulness extends to other applications that mini grinders perform, which include:

Several factors need to be considered when choosing the right mini grinder for specific needs. These include the strength of the tool, its accessory options, the level of noise it produces, the safety features it has, the speed at which it operates, and its durability and build quality.

One should look for a tool with a powerful motor to accomplish grinding tasks more efficiently. Motor strength is measured in watts, and a grinder with a strong motor can handle heavy-duty tasks and grind hard materials. Choose a grinder with various accessory options. Also, look for a tool that is not very noisy since excessive noise can harm hearing. This can be known by looking at the grinder's horsepower or decibel rating. Consider the safety features of a mini grinder also, like overload protection and blade guards. These can prevent accidents while using the tools.

Another thing to do is to find out if the grinder is durable and well-built. It should withstand regular use over time. Some grinders are made of plastic, which makes them less durable, so it's best to choose one made of metal, which is more sturdy.

Q1: How does a mini tool grinder work?

A1: The mini tool grinder has a motor-driven rotating wheel. The material to be ground is held against the grinding wheel, applying pressure until the desired shape or sharpness is achieved.

Q2: What are the differences between a mini tool grinder and a power tool grinder?

A2: Mini grinders are usually powered by electricity, while tool grinders are mainly powered by electricity or air. Additionally, mini grinders have smaller grinding wheels than tool grinders.

Q3: Is a mini tool grinder safe?

A3: Mini grinders are among the safest tools when used correctly. Users must ensure that their grinding tools are in good condition before use. Furthermore, proper PPE should be worn to minimize exposure to dust and debris.

Q4: Can you sharpen a mini grinder tool blade?

A4: Yes, tool blades can be sharpened using a mini tool grinder. However, one should ensure that the blade is compatible with the grinding wheel to achieve optimal results.