(446 products available)

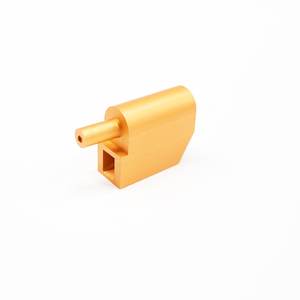

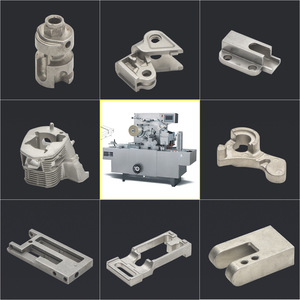

Types of MIM (Metal Injection Molding) casting include various methods used to make a wide range of metal parts economically. MIM is a process that integrates powder metallurgy and injection molding to manufacture small, complex net-shaped metal parts efficiently.

Components manufactured using the MIM process are easy to maintain, and only a few cleaning methods effectively keep the parts in good shape. The cleaning procedure is straightforward and only requires water, soap, and a brush.

Steps.

Cleaning metal-injected molded items follows these steps:

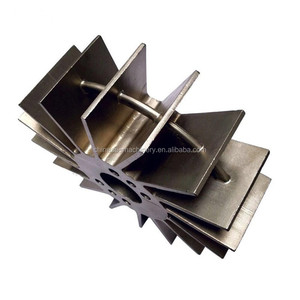

Aerospace Component Production

Aerospace engineers utilize MIM casting to develop intricate components in jet engines, turbine blades, and satellite structures. The technology ensures lightweight, high-strength, and heat-resistant parts that meet the rigorous demands of space applications.

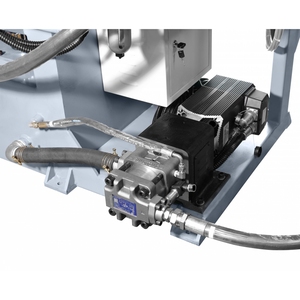

Automotive Industry MIM Components

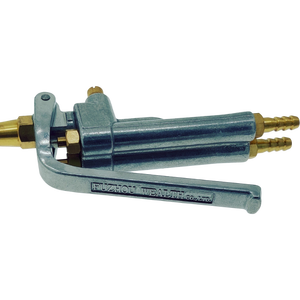

The automotive field uses MIM for parts like valve seats, transmission gears, and fuel injection components. The technology enables high-volume production of small, complex, and precision automotive components with excellent performance under high stress and temperature conditions.

Medical Device Manufacturing

Medical device manufacturers utilize MIM to produce complex parts for surgical instruments. The medical industry requires durable, easy-to-sanitize, and precision-formed surgical instruments and devices with small, complex shapes.

Jewelry and Decorative Object Design

Jewelry designers can use MIM to create intricate jewelry pieces such as earrings or bracelets. This method allows to cast delicate decorative details, eliminate visible joints, and reduce production costs.

Choosing suitable MIM casting products for investment can be a challenging task. But with the following tips, it can be easier.

Product application:

Know the product's application and the type of market it serves. Understanding these two factors' needs and demands can help one choose ideal products that customers will purchase without struggle.

Quality control standards:

When selecting MIM cast products, buyers should choose those manufacturers with specific quality control standards. Also, buyers should ensure that the products have passed relevant certifications. These are crucial for ensuring safety and reliability.

Customization options:

Many MIM manufacturing companies offer customization options, such as exclusive design and unique finishing techniques. Buyers can look for these types of companies if they desire an MIM product with a personal touch.

Pricing and minimum order quantities:

The pricing and the minimum order quantities should be considered when choosing MIM products to buy. Buyers should seek a product with realistic pricing that matches their budget. Also, they should choose products whose minimum order quantity aligns with their purchasing capacity.

Q1: What is the difference between MIM and traditional powder injection molding?

A1: Traditional powder injection molding involves molding materials in a bulk state, which can lead to poor material properties. MIMCasting, on the other hand, involves forming materials from fine powders, resulting in superior material properties.

Q2: What is the primary advantage of MIM casting?

A2: The primary advantage of MIM casting is its ability to produce small, complex parts at high volumes with widespread consistency. Furthermore, MIM casting offers a material yield that is practically 100%, making it an efficient choice for manufacturers.

Q3: What are some limitations of MIM casting?

A3: While MIM casting offers numerous advantages, it also has some limitations. The process can be expensive for low-volume production, and there may be design limitations due to the imposability of certain geometries. Additionally, the material choices, albeit extensive, are not as vast as those available for other casting methods.

Q4: Is MIM casting environmentally friendly?

A4: Yes, MIM casting is an environmentally friendly manufacturing process. The material yield of MIM casting is nearly 100%, producing very little waste. Moreover, the scrap material can be reprocessed and used again, further reducing environmental impact.