(26842 products available)

Metal grates, also known as metal grid flooring or grid panels, are load-bearing panels. They are made of interlaced strips of metal, which provide a surface that can be walked on. Metal grid flooring is available in different types and configurations. Here are some of them:

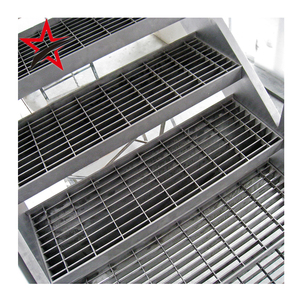

Bar Grate:

This metal grid has load-bearing bars running parallel. It is cross bars that run perpendicularly. This configuration creates a rigid surface. This surface is suitable for walkways, platforms, and industrial flooring. Bar grids offer high strength and durability. They also provide excellent ventilation and light. Bar grids are made from different materials. Examples include galvanized steel, aluminum, and stainless steel. These materials have different finishes. For example, galvanized and powder coating finishes enhance corrosion resistance.

Expanded Metal Grate:

This grid pattern is made from metal sheets. The sheets are slit and stretched to form a diamond-shaped pattern. This pattern creates a lightweight grate. It has high strength and rigidity. The open structure of the expanded metal grate allows airflow and light penetration. It reduces weight compared to solid metal sheets. This grate is commonly used in industrial applications. These applications include walkways, stair treads, and platforms.

Perforated Metal Grate:

This grid is made from metal sheets. The sheets are punched with patterns of holes. The holes can be arranged in circular, triangular, or square patterns. The arrangement depends on the design requirements. The perforated metal grate is lightweight. It allows airflow and drainage. It is also visually appealing. It provides aesthetic customization options. This grate is commonly used in commercial buildings, retail stores, and residential applications.

Welded Wire Grate:

This grid is formed by welding intersecting metal wires. It creates a rigid and stable walking surface. This surface has high load-bearing capacity. It is mostly used in agriculture, mining, and industrial applications. It is ideal for environments with high traffic and heavy loads. For example, machine shops and factories.

Swage Locked Grate:

This grid is made of closely spaced round bars. The bars are swaged (deformed) to lock them into cross bars. The result is a strong and stable floor panel. It is suitable for heavy-duty applications. These applications include heavy machinery, steel mills, and foundries.

Fiberglass Reinforced Plastic (FRP) Grate:

This grid is made from non-metallic materials. It consists of resin and fiberglass. The combination creates a lightweight and corrosion-resistant grate. It is suitable for highly corrosive environments. For example, chemical plants and wastewater treatment facilities.

Metal grates are used in various applications, including construction, home decor, automotive and manufacturing. Here are some common features and functions:

Durability

Metal grates are constructed from materials like steel, aluminum, or cast iron. This makes them resistant to rust, corrosion, and damage. For example, aluminum metal grates are more corrosion-resistant than steel. But steel has a high strength-to-weight ratio. This makes metal grates with steel able to bear greater loads without bending or breaking. The durability of these metal grates allows them to be used in different applications. For instance, industrial platforms, walkways, and heavy machinery surfaces.

Load-bearing capacity

These metal grates are designed to support weight. This is known as load-bearing capacity. Factors such as material type, thickness, and grate design affect load-bearing capacity. For instance, a thick steel grate will support more weight than a thin aluminum grate. Load-bearing capacity is important in applications like construction site access areas, where vehicles and people pass over the grate.

Ventilation and drainage

Metal grates have open patterns or spaces between the bars or strands. This allows air circulation and water to flow freely. The ventilation and drainage features promote airflow in areas like industrial settings and prevent flooding by allowing rainwater to drain off sidewalks and patios. The drainage feature also prevents the accumulation of debris and organic matter in gutters, which can cause blockage.

Slip resistance

Many metal grates have textures or patterns that increase friction. This prevents slipping and falling, especially in wet or oily areas. Slip-resistant grates improve safety in places like kitchens and industrial settings. Some metal grate manufacturers treat the surface of the grate with anti-slip coatings or add abrasive particles to the surface.

Customization

Metal grates can be customized in shape, size, and design to meet specific needs and requirements. This allows them to be used in different applications and industries. For example, metal grates for outdoor patios can be designed to fit in with the decor of the patio area. Customization meets functional and aesthetic needs.

Metal grates have different applications across various industries and sectors. Here are some common usage scenarios:

Construction and Architecture

Metal floor grates are used in walkways, bridges, and platforms in the construction industry. They offer a non-slip surface and are usually lightweight and high-strength. Metal grates for concrete are also used in buildings, industrial facilities, parking lots, and airports.

Utilities and Infrastructure

Metal grates are extensively used in stormwater management. They are installed in drain systems to allow water to pass through while filtering debris and solids. They are also used in sewage and wastewater management systems. The open area in the grates prevents clogging and facilitates the flow of water.

Power Generation

Metal grates are used in power generation facilities. They provide safe access to equipment and areas. They are also used in cooling towers, gas turbine enclosures, and biomass power plants. The grates allow airflow and reduce the accumulation of debris.

Manufacturing and Industry

Metal grates are used in factories, plants, and industrial facilities. They are durable and allow the passage of air and light. They are also easy to clean and maintain. Metal grates are used in areas like machine shops, production floors, and chemical plants.

Agriculture

Metal grates are used in agricultural settings. They are placed in animal housing and shelters. The grates are easy to clean and maintain. They also promote drainage and hygiene in animal shelters. Farm metal grates are also used in irrigation systems.

Marine and Offshore

Metal grates are used in ships, boats, and offshore platforms. They are corrosion-resistant and lightweight. Metal grates are used in walkways, decks, and engine rooms. They offer traction and are important for the safety of the crew and passengers.

Recreational Areas

Metal grates are used in public parks, stadiums, and sports facilities. They are used in pedestrian areas, ramps, and bleachers. The grates are durable, low maintenance, and can withstand heavy foot traffic.

Residential Applications

Metal grates are used in residential settings. They are used in driveways, patios, and decks. The grates complement outdoor spaces and enhance their aesthetic appeal. They are also functional and promote proper drainage.

There are many types of metal grates available for wholesale. Business owners should choose grate types that meet customer needs. Here are some factors to consider when selecting a metal grate:

Consider the Application

Customers purchase metal grates for different applications. Therefore, it is important to consider the intended application when selecting a metal grate. For example, drainage grates are installed on sidewalks, driveways, or gutters to cover and frame drainage areas. They allow water to flow into drainage systems and prevent debris from entering. This grate type is suitable for residential and commercial areas.

Decorative grates serve as covers for heating and cooling vents. They are installed on HVAC ducts to allow airflow in and out of vents. Decorative grates come in various designs to match home decor. They are ideal for residential applications.

Finally, Utility grates are used in industrial applications. They are designed to meet specific load-bearing requirements in factories, industrial plants, warehouses, and workshops.

Check the Load-Bearing Capacity

The load-bearing capacity of a metal grate shows how much weight it can support without damage or bending. Grates that will be installed in high-traffic areas or heavy machinery locations should have high load-bearing capacities. On the other hand, grates for residential applications can have a low load-bearing capacity.

Look at the Metal Type

Metal type affects the performance and durability of the grate. Choose a type that matches the expected environment. For example, stainless steel is suitable for salty, humid areas, and aluminum is lightweight and rust-resistant. Cast iron has a classic style and high strength, while galvanized steel is affordable and rust-resistant.

Check the Mesh Size

The mesh size of the metal grate affects the drainage efficiency. Larger mesh sizes allow for better drainage flow, while smaller mesh sizes trap smaller debris. Choose a mesh size that meets the customer's drainage needs.

Q1: What are the common types of metal grates used in construction?

A1: Metal fabrication companies make several different types of grates for contractors and homeowners. Some of the common types include; diamond shape, round, flat, serrated, and square/rectangular grates.

Q2: What are the common types of metals used to make grates?

A2: Metal fabricators use different types of metals to make grates. The most common ones are stainless steel, aluminum, and cast iron. Stainless steel and aluminum are popular choices because they are resistant to harsh weather conditions.

Q3: How can someone maintain their metal grate to keep it in good condition?

A3: Metal grate maintenance depends on the type and style. Generally, the maintenance process involves cleaning it to remove debris and rust. If the grate has a coating, the owner can hire a professional to reapply it to maintain its structural integrity and appearance.