(6158 products available)

A metal grate is a material made from metal bars or wires that are arranged in a pattern with spaces in between. It is used in different ways, such as letting air, water, and light pass through while being strong enough to hold weight. Metal grates come in many types, tailored for various applications and industries. Here are some of them:

Steel Grates

Steel grates are made from different types of steel. For example, carbon steel grates are made with a mix of carbon and steel, which gives them good strength and allows them to be shaped into different styles. Low alloy steel has a mix of metals like chromium and molybdenum, making the grate more durable and resistant to wear. Stainless steel is a popular choice because it does not rust and has a smooth, attractive finish. There are different types of stainless steel used based on where the grate will be used:304 stainless steel is resistant to rust and corrosion and is commonly used for grates that are not exposed to harsh conditions.316 stainless steel is more durable and resistant to corrosion because it has molybdenum added to its composition. It is often used in grates that are near saltwater or have high humidity.430 stainless steel is less expensive but still offers good strength and resistance to rust. It is often used in residential or light-duty applications.

Aluminum Grates

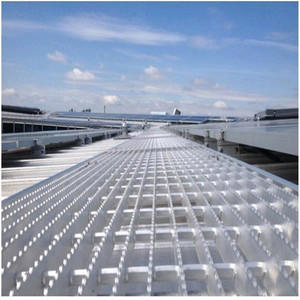

These grates are made from aluminum, a lightweight and non-rust metal. Aluminum grates are popular because they do not rust and are easy to move and install. They are used in places like swimming pool decks, where people walk a lot, and the grates allow water to drain easily. Aluminum grates come in two main types: extruded and stamped. Extruded aluminum grates are made by pushing aluminum through a mold to create strong, rigid bars with spaces between them. Stamped aluminum grates are made by cutting patterns out of flat pieces of aluminum to create grates with different designs that are also lightweight.

Wrought Iron Grates

Wrought iron grates are made from a type of iron that is shaped with very little carbon in it. This makes the grates look attractive because they have detailed and decorative patterns. Wrought iron grates are used in places where style is more important than weight because they can rust more easily and need maintenance to keep them looking good.

Metal grates are used in various applications, from industrial and commercial to residential and decorative. Some of their main functions include:

Walkable surface

Metal grates create walkable surfaces in various applications, including walkways, platforms, and catwalks. They offer safe and durable surfaces for pedestrian and vehicle traffic.

Load bearing

Metal grates are used in applications that require load-bearing capabilities, such as industrial flooring, heavy-duty shelving, and storage racks. They can support significant weights and loads.

Drainage

Metal grates are used in drainage systems to cover and protect drains, allowing water to flow through while preventing debris from clogging the drain. Examples include trench drains and channel drains.

Ventilation

Metal grates are used in HVAC systems to provide air circulation, cover vents and registers, and allow for the passage of air in and out of rooms. They are essential for proper ventilation and air flow.

Light transmission

Metal grates are used in applications that require light transmission, such as walkable skylights and light wells. They allow natural light to pass through while providing a safe walking surface.

Fire resistance

Some metal grates are fire-resistant and are used in applications that require fire safety, such as commercial kitchens, industrial facilities, and fire escape routes. They can help prevent the spread of fire.

Security

Metal grates are used in security applications to provide access control, cover windows and doors, and prevent unauthorized entry. They are essential for perimeter security and crime prevention.

Metal grates offer numerous features that enhance their performance and functionality in various applications. These include:

Durability and strength

Metal grates are durable and strong, making them suitable for heavy-duty applications. They can withstand wear, corrosion, impact, and weather elements.

Lightweight

Some metal grates, such as aluminum grates, are lightweight. This makes them easy to handle and install while maintaining strength and durability.

Slip resistance

Metal grates have slip-resistant surfaces that provide traction and prevent slips and falls in high-traffic areas and wet conditions.

Customization

Metal grates can be customized to different sizes, shapes, designs, and finishes to meet specific application requirements and aesthetic preferences. This includes welded steel grating and aluminum floor mats.

Metal grates serve various industries and applications due to their durable and functional features. Here are some common scenarios applicable for wholesale metal grates:

When choosing a metal grate for a specific application, several factors need to be considered. These include:

Load capacity and strength

Consider the load capacity of the metal grates. This refers to the weight that can be supported without bending or breaking. Look at the specifications to see the strength ratings. Higher ratings mean they can support heavier loads. Applications with high loads require metal grates with high load capacity.

Slip resistance

Slip resistance is an important safety feature for many applications. Some metal grates are more slippery than others, especially when wet or oily. Look for grates with slip-resistant features or textures. These have a better grip and reduce the risk of accidents.

Durability and corrosion resistance

Consider the durability of the metal grate. This includes the ability to withstand wear, impact, and environmental conditions without deteriorating. Some metal types offer higher durability, like stainless steel. Consider also the corrosion resistance. This is the ability to withstand rust or corrosion from moisture, chemicals, or extreme temperatures. It is important in harsh environments.

Weight

Determine if the weight of the metal grates is important. Some applications prefer lightweight materials that are easy to handle and install. Others need heavier options for strength and stability. Consider the project requirements and constraints.

Maintenance requirements

All metal grates need some form of maintenance to keep them in good condition. Consider the maintenance requirements. Some need regular cleaning and inspection while others need simple maintenance. Choose the one that fits the available resources and budget.

Aesthetic appearance

The aesthetic appearance is the visual appeal of the metal grates. This includes the design, style, and finish. Some applications prioritize function over aesthetics. Others need a metal grate that complements the surrounding decor.

Environmental factors

Environmental factors are the conditions in which the metal grates will be used. These include temperature, humidity, exposure to chemicals, and UV radiation. Extreme temperatures or high humidity require metal grates that can withstand those conditions. If they will be exposed to chemicals or UV radiation, choose the ones with higher corrosion resistance.

Q1: How are metal grates maintained?

A1: Metal grates are easy to maintain. Users should regularly clean them to remove debris and dirt. They can use a hose, pressure washer, and soap to clean the heavy duty metal grate. Users should also inspect the grates for damages and signs of rust. They should do touch-up painting if the grate is galvanized or aluminum to prevent rust.

Q2: Can metal grates be customized?

A2: Yes, metal grates can be customized. Various manufacturers offer metal grate customization. Users can send designs, specifications, and size requests to the manufacturers. They can choose the metal used for the grate and select the finishing options.

Q3: Are metal grates safe to walk on?

A3: Yes, metal grates are safe to walk on. They are durable and strong enough to support foot traffic. However, users should choose quality grates that are well-engineered and constructed from strong metals.

Q4: Do metal grates rust?

A4: Some metal grates can rust, especially those made from iron and steel. However, they are resistant to corrosion and rust due to aluminum's lightweight and durable nature. Users can also prevent rust by properly maintaining and cleaning the grates.

Q5: What are the common applications of metal grates?

A5: Metal grates are used in different applications. They are used in industrial areas, factories, and commercial spaces. Metal grates are also used in residential areas, outdoor spaces, and landscapes. They offer versatile uses and applications.

The keyword "metal grate material" has shown a notable average monthly web search volume of 8,100, with significant fluctuations over the past year. The web search volume experienced a 23% increase in the last three months and maintained the same percentage growth over the past twelve months.

Analyzing the monthly data reveals a pattern of varying interest in metal grate material. The web search volume dipped to 5,400 in January 2024 but rebounded to 8,100 by February and maintained stability through April. A peak occurred in July 2024 with 9,900 web searches, suggesting a seasonal increase, followed by a return to the average monthly volume in the subsequent months.

This trend indicates a cyclic interest in metal grate materials, possibly influenced by seasonal construction activities or real estate developments. The data highlights specific months where interest surges, potentially aligning with industry-specific demands or promotional campaigns within the construction and real estate sectors.