(9392 products available)

There are many types of metal floor grating for wholesale. Each type has different applications and unique features. Here are some common types of metal floor gratings:

Steel Bar Grating

Steel bar grating is a metal floor grid made of steel bars. It comes in two styles, namely; close and open web. The close steel bar grating offers a solid walking surface. It is ideal for applications where small debris can fall through the grate. This type of grating is popular in commercial and industrial environments. Open steel bar grating has a grid-like design. This design allows light, air, and water to flow through it. It is also known as drainage and light-weight steel bar grating. This type of grating is mostly used in high-traffic areas such as walkways, factory floors, and parking lots.

Fiberglass Reinforced Grating

Fiberglass reinforced grating is a lightweight grating made of fiberglass. It is non-corrosive and offers electrical insulation. This type of metal floor grating is popular in areas with high moisture levels. They include chemical plants, wastewater treatment facilities, and marine environments.

Aluminum Grating

Aluminum grating is a lightweight metal floor grating. It is resistant to rust and corrosion. This type of grating is popular in applications with aesthetic requirements. It can be finished with powder coating or anodized. Common applications of aluminum grating include airport walkways, drainage covers, and industrial platforms.

Pressed Steel Floor Grating

Pressed steel floor grating is made of steel strips. They are pressed together to form a grating pattern. The steel strips are usually 5mm thick. This makes the grating have a solid and anti-slip surface. This type of metal floor grating is popular in high-traffic areas. It is also easy to install and maintain.

Safety Grating

Safety grating is a metal floor grating with an anti-slip surface. It is ideal for areas where slip and fall accidents can occur. This type of grating is popular in commercial kitchens, swimming pool decks, and industrial spaces.

Metal floor grating is used in various industries for flooring applications. It is commonly used in walkways, platforms, stair treads, parking lots, industrial flooring, trench covers, catwalks, and more.

Metal floor grating is popular among contractors and engineers because of its many features. Some of the features include:

There are different applications and scenarios of metal floor grating to look out for, including:

Walkways and Pedestrian Paths:

Metal grating is used in walkways and pedestrian paths in areas with high traffic. They offer a durable and slip-resistant surface for pedestrians. They are used in constructing walkways in parks, industrial sites, and commercial buildings.

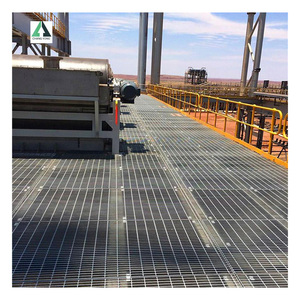

Heavy-Duty Platforms:

Metal floor grates are used in creating industrial platforms because of their strength and stability. They can withstand heavy loads and provide a safe working environment for employees. They also allow light and air to pass through.

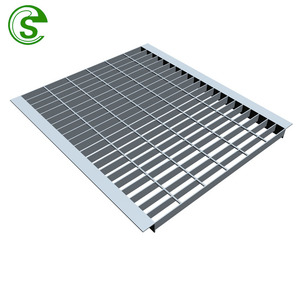

Drainage Areas:

Metal grates are placed over drainage areas to create a strong surface for vehicles and pedestrians. They prevent debris from entering the drainage system and allow water to flow freely.

Factories:

Metal floor grates are used in factories to create walkways and platforms. They allow water and spills to drain easily and prevent slips and falls. They are also used in areas where heavy machinery is operated.

Parking Lots:

Metal grating can be used to construct temporary or permanent parking lots. They distribute the weight of parked cars and allow water to drain through the gaps. This prevents water from pooling and promotes environmental sustainability.

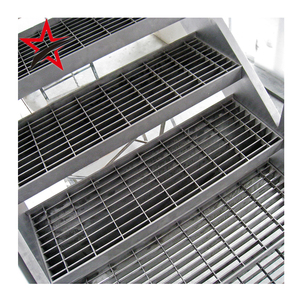

Stairs and Ramps:

Metal floor grates are used in constructing stairs and ramps in industrial settings. They provide a slip-resistant surface and allow light to pass through. They are also immune to harsh weather conditions.

Bridges:

Metal floor grates are used in constructing pedestrian and vehicle bridges. They are lightweight and durable, making them easy to install. They also allow water to pass through and reduce wind resistance.

Marinas and Docks:

Metal grating is used in marinas and docks because they are resistant to corrosion. They provide a slip-resistant surface for boats and ships and allow water to flow freely.

Power Plants:

Metal floor grates are used in power plants to create walkways and platforms. They are immune to chemicals and high temperatures, making them ideal for industrial use.

When choosing a metal floor grating for sale, wholesale buyers should consider several factors. Here are some of them:

Load-bearing capacity

Each application has different load requirements. For example, heavy machinery will exert a more significant pressure than a pedestrian walkway. Manufacturers should select metal floor gratings with high load-bearing capacity. This ensures safety and prevents collapses. Load tests can be done to validate the claims of manufacturers about the load capacity of the gratings.

Slip resistance

Metal floor grating is installed in areas with high moisture levels. As such, it must be slip-resistant to prevent accidents. Slip tests can be performed on various grating styles to determine their slip resistance.

Ventilation and drainage

Metal floor grating is used for industrial applications. It allows air circulation and light penetration. Therefore, buyers must choose a design that provides adequate ventilation and drainage. For example, close-out grating is suitable for areas that need high ventilation. It has small gaps between the bearing bars. On the other hand, welded grating is ideal for drainage. It has large gaps due to the welded intersections.

Corrosion resistance

Metal floor grating is used in different environments. Some environments expose it to harsh chemicals and moisture. Therefore, buyers must select gratings that can withstand such conditions. For example, aluminum and galvanized steel are suitable for corrosive and wet environments.

Compliance and standards

The Occupational Safety and Health Administration (OSHA) governs the use of metal floor grating in industrial applications. It has set some standards and guidelines to ensure the safety of workers. These include load capacity, span limitations, and the quality of materials. Business owners should ensure that the gratings comply with these standards to avoid legal issues and ensure safety.

Aesthetics

Metal grating can be used for architectural applications. In this case, buyers should consider aesthetics. They should choose a style that complements the design of the space. Loop tie grating has an attractive finish, and it is available in different designs.

Q1: What is the lifespan of metal floor grating?

A1: The lifespan of metal floor grating depends on several factors, including the type of metal used, environmental conditions, and maintenance. Galvanized steel grating can last 25 years or more, while aluminum grating has a longer lifespan and requires minimal maintenance.

Q2: Is metal floor grating easy to install?

A2: Installation metal floor grating is relatively straightforward, especially when using prefabricated panels. However, proper installation techniques are essential to ensure the stability and safety of the grating. It is recommended to have a qualified contractor install the grating.

Q3: How can metal floor grating be cleaned and maintained?

A3: Metal floor grating is easy to clean. It can be washed with a high-pressure water jet and cleaned with a wire brush. It requires high maintenance. Periodic inspection and replacement of damaged sections are recommended.

Q4: Can metal floor grating be customized?

A4: Yes, metal floor grating can be customized based on specific requirements. Customization options include material type, bar spacing, panel size, and surface finish. It is recommended to consult with a qualified manufacturer to discuss customization options.

Q5: What are the weight-bearing capabilities of metal floor grating?

A5: The weight-bearing capabilities of metal floor grating depend on factors such as material type, load classification, bar spacing, and support spacing. The load capacity of the grating is determined by the deflection and the maximum allowable stress. It is recommended to consult a structural engineer to determine the load capacity of the grating.

The keyword "metal floor grating" exhibits a notable trend in web search volume with an average monthly search count of 590. Over the past year, there has been a significant three-month increase of 50%, alongside a one-year change of 22%. The detailed monthly data from December 2023 to November 2024 shows fluctuating interest, with peaks in February and November at 880 and 720 web searches respectively, and lows in May, August, September, and October at 480 web searches each.

This keyword's trend demonstrates a pattern of peaks and valleys, which suggests seasonal variations or perhaps market-driven demand spikes. The highest web search volume was recorded in February, followed by a noticeable dip in the subsequent months until another rise in November. This pattern could indicate specific times of the year when construction and real estate projects are more likely to incorporate metal floor grating, possibly aligning with new building projects or renovations in the commercial sector.

Analyzing the reasons behind these fluctuations would require deeper insights into the construction and real estate market activities, including new project initiations, regulatory changes, or economic factors influencing construction budgets and material choices. However, the data clearly shows that despite the overall increase in yearly web searches, the demand for metal floor grating is subject to notable seasonal adjustments.