(37267 products available)

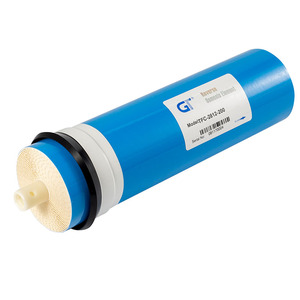

The reverse osmosis process involves pushing molecules through a membrane in RO systems that filters out anything except pure water. Usually, the reverse osmosis membrane types are divided into two main categories based on the material they are made of.

Synthetic Polymers

Two major varieties of synthetic polymers are used in reverse osmosis membranes: thin-film composite (TFC) and polyamide (PA):

Thin-Film Composite Membranes (TFC):

TFC membranes combine multiple layers, each with its own unique properties. The natural polymer cellulose is one of the membrane's construction components. While functioning under high-pressure conditions, TFC membranes achieve high rejection rates for dissolved solids, bacteria, viruses, and other contaminants. These membranes are now being used in the vast majority of modern reverse osmosis water filtration systems.

Polyamide Membranes (PA):

Iceberg RO systems use polyamide (PA) membranes as their selective barrier for reverse osmosis. PA membranes are notable for their thin film and flat sheet construction, which is made up of multiple strands coiled around a central tube. Because of their outstanding chlorine tolerance and performance, PA membranes offer a dependable and effective method of removing impurities from water while allowing clean water to pass through.Synthetic polymers are widely used in reverse osmosis membranes because they can achieve a good balance between water permeability and contaminant rejection. Nevertheless, because changing conditions and demands can have a significant impact on water quality, membrane choice is essential.

Natural Polymers

Natural polymers, notably cellulose acetate, have historically been significant in reverse osmosis membrane technology. Water molecules can pass through the membrane, while bigger molecules like dissolved salts and contaminants are blocked by the arrangement of cellulose acetate molecules. Water purification systems utilized cellulose acetate membranes as their selective barriers as early as the 1970s. Nonetheless, due to their salt rejection capacity and constant water flow, TFCA membranes gained prominence with technological breakthroughs and became nearly universal in contemporary reverse osmosis devices. Nevertheless, some water filtration systems still use cellulose acetate membranes.

The specifications for the reverse osmosis membrane are as follows.

The membrane in RO systems finds application in multiple industries in different usage scenarios, as highlighted below.

Desalination plants

Membrane filters are the core component in reverse osmosis desalination plants. The plants utilize high-pressure water pumps to push seawater through the RO membranes. The membrane separates the seawater into freshwater suitable for human consumption and brine that gets disposed of in the ocean.

Drinking water purification

RO systems with membranes purify unfiltered water to manufacture clean and potable water. The purified water is suitable for drinking directly or serving as an ingredient in food production.

Industrial water treatment

Many manufacturing industries utilize membranes in their water treatment facilities. The membranes filtrate contaminants like minerals and chemicals from the water. As a result, water with the right quality and consistency for industrial processes is produced.

Food and beverage industry

The food and beverage industry employs RO membranes to concentrate liquid food products like fruit juices, remove flavors and smells from water used to manufacture final products, and extract valuable components like lactose and acids.

Microelectronics and semiconductor manufacturing

Microelectronics and semiconductor manufacturing industries need pure water with very low total dissolved solids (TDS) levels. To achieve this, the industries use membranes in reverse osmosis systems to remove contaminants like ions and microorganisms from the water.

When buying RO water filter membranes, buyers should begin by researching different types of reverse osmosis membranes and how they work. Understanding how each membrane works will enable buyers to choose suitable ones for their target customers.

Potential buyers should consider the material used to manufacture the membranes they want to buy. As discussed earlier, RO membranes are manufactured using several materials, each with distinct benefits and applicability. Therefore, buyers should choose the membrane materials that align with their customers' needs and preferences.

Buyers should also consider the specific contaminants the intended users want to remove. Some buyers may want to remove minerals, while others want to remove microorganisms and certain chemicals. To achieve the desired water quality, buyers should select RO membranes specially designed to eliminate specific contaminants.

Additionally, buyers should evaluate the flow rates and water production capacities of the available RO membranes. Different RO membranes have different flow rates and water production capacities. Consideration of this factor will enable buyers to choose membranes that meet their customers' consumption needs.

Moreover, buyers should choose membranes that fit well with existing filtration systems. Buyers should consider the configuration and dimensions of a membrane. They should choose membranes that fit well with their customers' existing water filtration setup to avoid additional costs and complexities associated with retrofitting.

Buyers should also consider the lifespan of the membranes they want to purchase. Some membranes may have shorter lifespans, while others have longer lifespans. If the customers' users regularly replace the membrane filters, buyers will spend more than if they purchased those with longer lifespans. The longevity of the membranes will determine the cost buyers' end users will incur.

Buyers are advised to purchase membranes from reputable manufacturers and suppliers with a proven track record. Such suppliers and manufacturers offer membranes with optimum performance and dependability. Also, buyers should ask the suppliers about installation requirements and technical support to ensure their customers benefit from the membranes they will purchase.

Q: How does a reverse osmosis membrane work?

A: The membrane itself is a thin, semi-permeable layer folded into a plastic, tea-bag-shaped container, and it allows only water molecules to squeeze through while rejecting larger molecules, ions, and particles. Pure water is then collected in the storage tank, and contaminates are left behind in the ro filter.

Q: What elements does the reverse osmosis membrane filter out?

A: The reverse osmosis system can remove contaminants such as fluoride, lead, chlorine, nitrates, sodium, pesticides, sulfide, arsenic, and some pharmaceutical products and chemicals.

Q: How long do RO membranes last?

A: RO membranes generally last 2 to 3 years, but they may last longer with regular maintenance and filter changes. Some high-quality membranes may last up to 5 years.

Q: How can someone tell if the RO membrane is damaged or not working?

A: If contaminants are found in the water, like TDS, or if the water pressure is low, or there is an increase in water waste, then the RO membrane may be damaged. In such cases, it is better to identify the membrane's damage and get it replaced immediately.