Introduction to Material Handling Systems

Material handling systems are crucial components of modern industrial operations, serving as the backbone for efficiently managing the flow of materials and products through various processes. These systems streamline operations, enhance productivity, and ensure smooth logistics in warehouses, distribution centers, and manufacturing plants.

By integrating technology and innovative design, material handling systems not only minimize manual effort but also reduce the risk of injury, material damage, and inefficient workflows. Understanding the different types, features, and applications of material handling systems is essential for businesses aiming to optimize their operations.

Types of Material Handling Systems

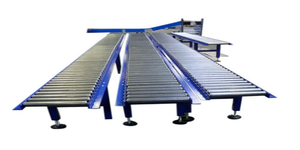

- Conveyors: These systems efficiently move materials from one point to another, reducing manual labor and enhancing speed.

- Automated Storage and Retrieval Systems (AS/RS): Designed for high-density storage, AS/RS automatically store and retrieve materials using specialized machinery.

- Pallet Racking Systems: These systems maximize storage space, providing organized areas for palletized goods.

- Mobile Material Handling Equipment: Includes forklifts, pallet jacks, and towing tractors that enhance the flexibility of material movement.

- Robotic Systems: Emerging technology that automates material handling tasks, improving efficiency and precision.

Function, Feature, and Design of Material Handling Systems

- Function: Material handling systems are designed to store, protect, and control materials. Their main functions include:

- Transporting materials through various stages of production.

- Storing materials in an organized manner.

- Sorting and distributing products as required.

- Features: Notable features of advanced material handling systems are:

- Automation capabilities for increased efficiency.

- Real-time tracking systems to monitor inventory levels.

- Modular design for customized configurations.

- Energy-efficient machines to reduce operational costs.

- Design: The design of material handling systems focuses on:

- Ergonomics to minimize operator strain.

- Durability to withstand heavy usage.

- Safety features to protect workers and materials.

Applications and Advantages of Material Handling Systems

- Applications: Material handling systems are employed across various industries, including:

- Manufacturing: To facilitate production processes.

- Warehousing: For efficient storage and retrieval of goods.

- Retail: To streamline inventory management and logistics.

- Food and Beverage: To handle bulk materials safely and hygienically.

- Advantages: Incorporating a material handling system brings several benefits:

- Increased efficiency and productivity.

- Enhanced safety for workers.

- Lower operational costs through reduced manual labor.

- Improved accuracy in inventory management.

- Flexibility to adapt to changing operational demands.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4