(458 products available)

Ready to Ship

Ready to Ship

The mastic membrane is a liquid waterproofing material that forms a watertight barrier when applied to a substrate. It comes in two main types:

Polymer-modified bitumen mastic membranes are used in various construction projects. They include the following specifications:

Maintenance of the mastic membrane is crucial for ensuring long-term performance and preventing premature failures. Here are some maintenance tips:

Structural waterproofing:

Mastic membranes are widely used for structural waterproofing, protecting critical structures like basements, foundations, and decks from water infiltration. They can be applied to various substrate surfaces, including concrete, masonry, and metal.

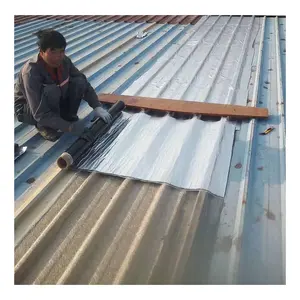

Roofing membranes:

Mastic membranes serve as roofing membranes, providing waterproofing and protection to roofs in commercial, industrial, and residential buildings. They can be used in different roofing systems, such as built-up roofs (BUR), modified bitumen roofs, and single-ply roofing.

Traffic coating:

Mastic membranes are used as traffic coatings to provide waterproofing and protection to surfaces subjected to pedestrian or vehicular traffic. They are commonly used on parking decks, floors, walkways, and terraces.

Wet areas:

Mastic membranes are suitable for waterproofing wet areas, such as bathrooms, kitchens, balconies, and terraces. They create a waterproof barrier, preventing water leakage and protecting underlying structures.

Detailing and joint sealing:

Mastic membranes are used for detailing and joint sealing in waterproofing applications. They can be used to seal joints, cracks, andREGION_OTHERDETAILS openings, providing additional waterproofing integrity in vulnerable areas.

Wind-driven rain and water scour:

Mastic membranes offer effective protection against wind-driven rain and water scour. They create a durable waterproof barrier, preventing water penetration in high-exposure areas, such as coastal regions or locations prone to heavy rainfall.

Green and solar roofs:

Mastic membranes play a crucial role in green and solar roof systems. They provide waterproofing protection for the structural elements of the roof while allowing for sustainable design practices and energy-efficient solutions.

Application requirements:

Business buyers need to understand the specific application requirements for using the mastic membrane. Consider factors like surface type, climate conditions, and performance needs. Select a mastic membrane that is compatible with the substrate and can meet the particular performance demands of the application area.

Quality and standards:

Choose mastic membrane materials manufactured according to recognized quality standards. Check product certifications and ensure they adhere to specified quality and performance criteria. Select reputable brand products to ensure the quality and reliability of the mastic membrane.

Cost-effectiveness:

When purchasing a mastic membrane, consider its cost-effectiveness. Compare prices among different brands and specifications while considering the membrane's quality, performance, and service life. Choose a mastic membrane that offers good value for money to ensure business profitability.

Supply and service:

When purchasing mastic membranes in bulk, buyers need to consider the supplier's ability to provide stable product supply. Choose suppliers who can ensure timely delivery and adequate product supply. Additionally, consider the technical support and after-sales service offered by the supplier. Select suppliers who provide comprehensive technical assistance and responsive after-sales support to ensure prompt resolution of any issues that may arise during use.

Sustainability:

Opt for mastic membranes that are produced sustainably and have environmentally friendly properties. Consider factors such as recyclable materials and low VOC emissions to minimize the environmental impact of business operations and enhance corporate social responsibility.

Q1: How long can mastic membranes last?

A1: Mastic membranes can last 10-15 years, depending on factors like climate, maintenance, and membrane quality.

Q2: Can mastic membranes be repaired if damaged?

A2: Minor damages to mastic membranes can be repaired using patch kits. However, if the damage is extensive, it may be necessary to consider membrane replacement.

Q3: Do mastic membranes affect building energy efficiency?

A3: Mastic membranes play a crucial role in enhancing a building's energy efficiency by preventing air and water infiltration. Their implementation can result in significant reductions in energy consumption.

Q4: What is the difference between mastic membranes and other types of membranes?

A4: Mastic membranes differ from liquid-applied and sheet membranes. They are durable, resistant to UV rays, and ideal for pool and intensive foot traffic areas.