Introduction to Machine Laser Technology

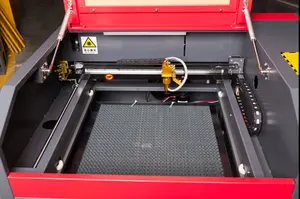

Machine laser technology has revolutionized various industries, offering unparalleled precision and efficiency for cutting, engraving, and marking materials. These advanced tools utilize a concentrated beam of light to achieve highly accurate results, making them indispensable in manufacturing, design, and construction environments. The versatility of machine lasers allows for applications across a broad spectrum, adapting to different materials and project specifications.

Types of Machine Lasers

There are several different types of machine lasers, each catering to specific needs and applications:

- CO2 Lasers: Ideal for cutting and engraving non-metallic materials like wood, acrylic, and leather. They are well-suited for applications requiring intricate designs.

- Fiber Lasers: Perfect for metal processing, these lasers deliver high efficiency and excellent beam quality. They excel in cutting, marking, and welding various metals.

- Diode Lasers: These compact lasers are often used in small-scale applications like engraving and laser pointers. They are energy-efficient and cost-effective for simpler tasks.

- YAG Lasers: Known for their versatility, YAG lasers work well with metals and plastics, making them suitable for more industrial applications.

Function, Features, and Advantages of Machine Lasers

Machine lasers come loaded with features that enhance their functionality, making them essential in today's industrial landscape. Here are decisive advantages:

- Precision and Accuracy: Machine lasers offer exceptional precision, allowing for intricate designs and fine details that are hard to achieve with traditional methods.

- Speed and Efficiency: The rapid processing capability of machine lasers means faster turnaround times for projects, significantly improving productivity.

- Minimal Material Waste: Lasers cut materials with minimal kerf (the width of the cut) resulting in less waste and more cost-efficient production.

- Low Maintenance: Unlike other machines, lasers generally require less maintenance, reducing downtime and operational costs.

Applications of Machine Lasers

The uses of machine lasers span a diverse range of industries, showcasing their adaptability:

- Manufacturing: Used extensively for cutting sheets of metal, engraving product identifiers, and creating intricate designs.

- Signage and Displays: Ideal for creating detailed signs, displays, and promotional materials through cutting and engraving.

- Textiles: Used for cutting fabric and leather with high precision, allowing for unique designs in apparel and upholstery.

- Aerospace and Automotive: Machine lasers are employed for essential processes such as welding and marking in the manufacturing of precision parts.