(798 products available)

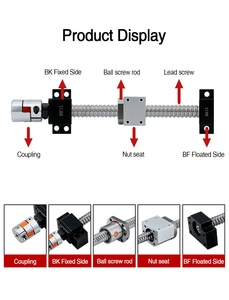

A lead screw is a type of screw used to convert rotational motion into linear motion, commonly used in power screws, machine tools, CNC thread, lathes, and milling machines, among other applications. They are manufactured to move objects, in which case the screw will move when rotated. A left-hand lead screw is the opposite case, where it moves counterclockwise.

As per its types, the left-hand lead screw is mainly divided into 4 categories, as explained below:

Lead screws are supposed to last for a long time. So users must know the appropriate methods to maintain them. Knowing the maintenance tips can help to choose the right lubrication. Also, the maintenance tips can tell the users which cleaning method to use and why some areas wear out faster than others. Neglecting the screw's care will result in uneven or jerky movements, a noisy mechanism, and, eventually, faster damage.

Using a vacuum to remove dust and debris from the screw is the best cleaning method. A brush attachment with soft bristles can help clean the screw thread without damaging it or taking off the lubricant. The brush will ensure that no dust is pushed into the threads. The user can remove large debris or caked dust. However, if the dust is too much and a brush is required for cleaning, it is better to take out the lead screw and clean it while it is off the device.

Dust, dirt, and debris are the biggest enemies of a lead screw support the left hand thread. Users should avoid dirt buildup by regularly using a vacuum to remove small particles. Lubrication is essential for reducing wear and tear and prolonging the lead screw's life. The type and amount of lubrication to use will depend on the application of the lead screw. Oil-based lubricants are ideal when there is a heavy load or fast speed. Grease is a better option for lead screws with low speed and light loads. Regardless of the type, users should ensure that the lubricant can withstand exposure to heat from friction. The lubricant should also repel dust and dirt to prevent any buildup around it.

The most parts of a lead screw require lubrication except for the threads that connect to the nut. Lubricate the housing, rod/stem, and bushings. On the other hand, the threads need to remain dry because dirt can quickly accumulate on them, and cleaning them regularly can be difficult. However, the lead screw will require lubrication from time to time. The nut also requires lubrication on its inner threads.

Some areas may require more lubrication because of constant friction. Users should pay attention to areas that rub against each other and apply grease regularly. They should also inspect the mechanism and wipe out the debris before applying fresh grease. There is usually a wear pattern on the lead screw and nut. The load-bearing areas usually develop a wear pattern. Users should wipe out the debris in the load-bearing areas and inspect them for even wear. If there are signs of uneven wear, it may be an indication that the thread requires lubrication or there is damage, and inspection is necessary.

Robotic joints and vehicles:

Left-hand lead screws are employed in robotic joints where robots need to twist or rotate in different directions. They are also used in left-hand threaded joints. In such scenarios, left-hand lead screws are combined with right-hand lead screws, as is typical in most robotic applications. This combination may be useful for creating a ropes system. A ropes system employs guide pulleys that change the direction of the ropes. Here, both right-and left-hand lead screws work together to convert the motor rotation into linear movement for moving the pulley wheels and the ropes.

3D printers:

Typically, 3D printers depend on screws for their vertical movement. Some G 3D printers may use left-hand lead screws on their Z-axis to achieve vertical movement of the print bed or axis.

Actuators and vices:

For vices that require precise linear motion and high compression, a lock grab employs a left-hand screw thread for securing objects, but usually, right ones. An actuator is a device or motor used to achieve movement and control in a system. The SV or linear screw actuator design employs a screw thread mechanism for achieving linear motion. Left-hand lead threads are common in many SV linear screw actuator designs.

Separator machines:

The columator or separation machine uses a left-hand threaded screw in its mechanism. As the name suggests, the machine is designed to separate or diffuse substances, such as particles or fluids, in different directions. Left-hand threaded screws offer support, stability, and movement for the separating actions.

Right hand and left hand lead screws are designed to move in opposite directions when rotated. In order to choose the correct type of lead screw for a particular application, one must consider the following factors.

Load and force requirements

The application’s load and force requirements must be determined, including the weight of the item to be moved and whether it will require additional turning or pulling force. Once the load and force requirements are known, the shaft’s diameter and length can be chosen to ensure that it can support the required load without bending or breaking. The thread count and positioning also need to be considered so that enough force can be generated to move the load.

Speed and acceleration

Determine the speed and acceleration needed to move the load in the application. Once the speed and acceleration are known, the nut and thread design should be chosen based on the desired speed. Higher speeds require a greater thread count, and faster acceleration requires a larger diameter nut to generate the necessary torque.

Guidance system

The appropriate guidance system should be picked based on the application’s support and alignment needs. For example, in applications with high radial loads, a linear bearing may be needed for guidance. Alternatively, a lead screw and pillow block setup could be a suitable low-cost option for simpler applications.

Environmental factors

Consider the environmental aspects of the application, such as the presence of dust or debris, corrosive materials, or high-temperature conditions. Select a lead screw material and coating that can withstand the environment, like stainless steel for corrosive settings or a self-lubricating nylon nut for dusty environments.

By carefully examining these elements, the right type of left hand screw thread can be chosen for specific mechanistic needs, ensuring effective and reliable performance.

Q1: Why does the lead screw's direction matter?

A1: The direction of the rotation matching the movement of the intended part is vital for correct assembly, working, and mechanical design.

Q2: Are left hand lead screws more expensive than righties?

A2: In general, left hand lead screws are slightly more expensive because they are produced in lower quantities. The price difference is usually not large enough to affect ordering for wholesale.

Q3: Can all nut designs work with left hand lead threads?

A3: No, the nut must have a thread profile that matches the left hand lead screw. In this case, the thread shall be cut to conform to the left handed lead screw making it to work effectively.

Q4: Are any specific lubricants needed for left hand lead screws?

A4: No, any suitable lubricant for steel lead screws can be used. It is important to choose the right lubricant to enhance and prolong the lifespan of the lead screw.