(209843 products available)

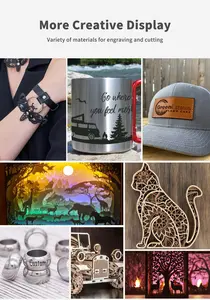

Laser machines for home are categorized based on the type of laser they employ. Such machines have become quite handy for various home-based tasks, from crafting to engraving and cutting.

CO2 Laser Machines

Commonly used in engraving and cutting, the CO2 laser machines use carbon dioxide as the laser gas. CO2 lasers cut materials like wood, acrylic, and glass and are famous for their precision. Their applicability in diverse material cutting makes them a mainstay in the home workshop, especially for handicrafts and modeling.

Fiber Laser Machines

Fiber laser machines use a solid-state laser that produces a highly concentrated beam, often for metal engraving and cutting. Because of their efficiency, these machines are perfect for homeowners dealing with metal crafts or auto parts. This machine ranks higher as a metal engraver compared to the CO2 laser machine.

Diode Laser Machines

These lasers are among the most frequent entry-point home laser machines. Typically, these machines are suited for engraving and are especially handy for beginners. Some high-powered diode lasers can even cut thin materials. However, for robust tasks, users may need to consider different laser machines.

YAG Laser Machines

Home users rarely use these machines; however, they are categorized under industrial-grade machines. Great for engraving and marking, the YAG machines utilize a rod-shaped crystal as the laser medium. These machines are still common for specific high-end home tasks.

Various industries employ laser machines for cutting and engraving purposes. The precision and flexibility of lasers make them an important tool for numerous tasks.

Manufacturing Industry

In the modern manufacturing industry, laser technology is crucial. Laser machines assist in the accurate cutting and shaping of materials such as metals and plastics. As the need to create detailed machinery parts or equipment increases, lasers help meet that demand due to their accuracy.

Automotive Industry

Many manufacturers in the automotive industry use laser machines for welding and cutting car components. Since lasers have great precision, they can handle complex designs or intricate patterns that play a role in improving the automobile's aesthetics and functionality. Lasers efficiently create detailed dashboard parts or light covers with minimal errors.

Aerospace Industry

The aerospace industry employs laser machines to enhance safety and performance. Laser cutting helps create light yet strong components to reduce the aircraft's weight. Lasers can also work on complicated materials that are hard to cut by many other means. These attributes make them a standard tool for manufacturing aircraft parts.

Jewelry and Watchmaking

The jewelry and watchmaking industries often use laser machines for engraving intricate designs on watches and other jewelry pieces. The accuracy of lasers permits minute details that enhance products' elegance and sophistication. Lasers are equally efficient when working with delicate materials like gold, silver, and gemstones.

Electronics Manufacturing

In electronics manufacturing, laser machines are used to mark products for scanning or engraving logos and other identification information. Additionally, lasers help cut PCBs (printed circuit boards) or other parts connected to electronic equipment. With the ever-growing demand for precise high-tech gear, laser machines will remain important in this industry.

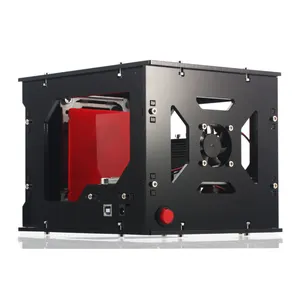

Before purchasing a laser machine for home, knowing the important features and product specifications is vital. Key attributes partially define the machine's operational efficiency, versatility, and ease of use.

Laser Types

LASIK surgical induction machines are mainly of three types: CO2, fiber, and diode. CO2 lasers serve best for engraving and cutting non-metal materials like wood and acrylic. Fiber lasers offer great efficiency in engraving and cutting metal items. Home users mainly go for diode lasers since they tend to be the more accessible option of the three.

Laser Power

The power of a laser influences its efficiency in engraving or cutting a particular material. A laser machine with a power output of 40-60 watts is ideal for home use and general light projects. However, for more industrial-style projects, go for higher power output machines.

Working Area

The working area, also known as the bed size, refers to the space available to the laser to carry out its activity. A large work area is appropriate for those intending to carry out large-scale projects. For laser novices or those with small jobs, a machine with a small working area will suffice.

Software Compatibility

Most laser machines utilize specific software for operation. These laser machines are usually compatible with design programs like Adobe Illustrator or CorelDRAW. While some machines come with standard software packages, others allow the user to employ various applications for better results.

Safety Features

Numerous safety features are vital for operating a home laser machine. Look out for devices like lid safety switches or optical sensors that detect the presence of materials on the machine bed. These features assist in preventing mishaps and promote safer operation.

Various elements have to be considered when engaging in a home laser machine business. These aspects influence market entry, profitability, and business sustainability.

Market Demand

The desire among hobbyists and professionals drives the demand for home laser machines. Many consumers currently prefer personalized items and detailed handicrafts, which laser machines effectively create. As a result of the growing interest in DIY projects, the market for these machines expands, creating a new opportunity for businesses.

Initial Investment

The initial investment for a laser machine can be a little high, depending on the type of machine a buyer chooses. While beginner-friendly machines with a lower watt count are more affordable, laser-cutters and engravers with industrial-grade performance are costly. Business owners should clearly understand financing options and the long-term benefits before investing in a home laser machine.

Business Models

A few business strategies could be useful for companies planning to enter this market. These machines promote the establishment of service-based businesses that offer engraving and cutting services to local customers. Another model is to manufacture and sell the machines directly to interested consumers. Companies can also provide design templates or related materials to support the enthusiasts engaging in laser cutting at home.

Marketing Strategies

To attract customers, companies must apply efficient promotion strategies. They could show off the many creations made utilizing the laser machines on social media platforms like Instagram and Pinterest. Offering reductions or showcasing the competitive advantages of their machines can further convince prospective customers. Companies can also promote their machines at trade exhibits or fairs focusing on crafts and technology.

Customer Support

Providing great customer service becomes essential for customer satisfaction and loyalty. Companies should ensure their customers access installation advice and a responsive helpdesk. Additionally, offering online how-to videos and a forum for machine owners to connect could enhance the consumer experience.

There are a few factors that one must consider when purchasing a laser machine. These factors directly impact how well the machine performs key laser functions, such as cutting and engraving.

Laser type

When it comes to home use, CO2, diode, and fiber machines are great options. CO2 laser machines handle most non-metal materials such as wood, leather, and acrylic. Buyers interested in metal engraving or cutting should consider appointing a fiber laser machine. A diode laser machine is suitable for novices because of its relatively affordable price and ease of use.

Power

Power is a crucial consideration because it determines how well the machine can cut or engrave. A machine with a 40-60 watt power output will suffice for general home use, such as crafting. A higher watt count is necessary for industrial work or thicker materials. For expert advice, refer to a laser machine power rating guide.

Bed size

Bed size determines the project scope the machine can handle. For crafters with small-scale projects, a machine with a small work area will suffice. Large machines are ideal for users intending to take on larger tasks. A laser machine with a large working area enables users to realize more without having to change setups constantly.

Software

Appropriate software ensures smooth operations. Many machines utilize user-friendly software for program design, such as LightBurn. A few machines are compatible with widely used design programs like CorelDRAW and Adobe Illustrator. Buyers should ascertain the software options before purchase, especially if they use specific design tools.

Budget

Budget is an important consideration for what type of laser engraving machine to buy. The price varies based on the type of laser and the machine power. While acquiring a laser machine requires a reasonable budget, one must evaluate the machine's prospective performance and features. These factors determine how well it meets the user's needs.

A1. CO2 and diode machines are best for home use because of their effectiveness in cutting and engraving. These machines efficiently process materials such as wood.

A2. People use laser machines at home for crafting, engraving personalized items, creating jewelry, and architectural models.

A3. A stronger laser machine can cut through materials like acrylic and wood that are about one inch thick.

A4. Homes ensure safety by including safety switches on the machine lid and by utilizing a laser machine with a smoke and fume extractor.

A5. It is important to have a sufficiently ventilated area with an electric source and appropriate fume handling for the optimal operating setup.