Introduction to Laser Cutting Machines for Iron

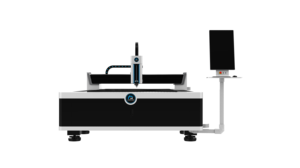

Laser cutting machines for iron represent a revolutionary advancement in the metal processing industry. These powerful tools utilize high-intensity laser beams to cut through iron with precision and speed, making them an essential piece of equipment for various manufacturing sectors. From intricate designs to heavy-duty applications, laser cutting technology offers unmatched efficiency and accuracy, transforming the way businesses approach metal fabrication.

Types of Laser Cutting Machines for Iron

- CO2 Laser Cutting Machines:

- Utilize carbon dioxide as a laser medium, ideal for cutting thin sheets of iron.

- Offer high cutting speed and are known for their cost-effectiveness.

- Fiber Laser Cutting Machines:

- Employ fiber optics to generate lasers, making them suitable for thick iron sections.

- Provide superior energy efficiency and faster processing capabilities.

- Nd:YAG Laser Cutting Machines:

- Use a solid-state laser, ideal for precise and complex metal cutting tasks.

- Commonly used in specialized applications such as engraving or when high-quality finishes are needed.

Applications of Laser Cutting Machines for Iron

- Manufacturing: Used extensively for producing parts, assemblies, and components in sectors like automotive and aerospace.

- Construction: Key in creating structural elements, intricate designs for ornamental applications, and custom building solutions.

- Art and Design: Artists and designers use laser-cut iron to create stunning installations, signage, and art pieces.

- Jewelry Making: Allows for delicate and customizable pieces, offering precision that is difficult to achieve through traditional methods.

Features and Advantages of Laser Cutting Machines for Iron

- High Precision:

- Laser cutting offers superior accuracy, enabling complex cuts with minimal tolerances.

- Results in clean edges and reduced need for finishing processes.

- Speed:

- Laser machines can cut through iron materials quickly, enhancing overall productivity.

- Allows for faster turnarounds on projects due to reduced downtime.

- Flexibility:

- Capable of cutting a wide range of iron thicknesses and designs with ease.

- Customizable settings to accommodate various production needs.

- Minimal Material Waste:

- Laser cutting produces less scrap compared to traditional cutting methods.

- Efficient use of materials contributes to cost savings and sustainability.

How to Choose a Laser Cutting Machine for Iron

- Assess Material Thickness:

- Determine the thickness of iron you intend to cut to select a machine with appropriate power specifications.

- Consider Cutting Speed:

- Evaluate the speed requirements of your projects to ensure the machine can meet your production goals.

- Review Operational Costs:

- Analyze the energy efficiency and maintenance costs associated with the machine type you choose.

- Manufacturer Reputation:

- Research manufacturers for product quality, service support, and warranty options.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4