(5 products available)

As a small desktop CNC router, the JD6090L CNC router is easy to use and affordable for both home business owners and hobbyists. This machine suits designing and creating crafts like signage, artwork, and small furniture pieces.

However, mini CNC routers are not the only type available on the market. Here are the four most common types of CNC routers manufactured and supplied worldwide:

JD6090L Mini CNC Router:

This CNC machine is perfect for those who need a bit more room to work. The JD6090L has the same design but a bigger workspace. It also has the same features, including the use of an electric spindle or laser engraving unit. Like its smaller version, this machine is user-friendly, easy to operate, and affordable.

Jewel JDZ-1 CNC Router:

The Jewel router is small, light, and compact in size. It is an ideal machine to engrave rings, bracelets, and other delicate jewelry pieces. The hassle-free operation of this machine allows operators to create beautiful and intricate designs tightly.

JD-7D CNC Router:

This desktop CNC router machine is an affordable entry into the world of 3D carving and engraving for wood, plastic, glass, bamboo, and other soft materials. The user-friendly design makes it perfect for newbies to the craft. Spindles or laser units do the etching, and the software allows effortless operation.

Standard CNC Router:

When it comes to size, this machine is standard and bigger than most models. The working table is set up for large pieces of material to be used in sign-making and for carving and engraving objects like flutes, candlesticks, and other large spindle-turned cylindrical objects. The table in this router can be further extended, so oversized and large sheets of material can also be used. Varying from 1.2m to 2.4m, extensions can be added to lower the cost of an CNC router machine with a small through large production capacity.

The standard CNC router machine usually has a CAD and CAM system so that any required changes around the design process can be done effortlessly and easily.

Rugged CNC Router:

Usually made from aluminum, the rugged standard CNC router machine is sturdy and well-built for durability without compromising its lightweight construction, which allows it to have a high speed of operations. This machine has a dedicated, fully enclosed motor and a simple-to-use, multi-solenoid router interface.

The specification of the JD6090L CNC router machine will tell what it can do. Generally, the specifications will include the dimensions, work area, router motor power and voltage, cutting speed, and materials compatibility.

Users of the JD6090L router should follow some maintenance tips to keep the machine running smoothly. The most important tip is to clean the rail and slide track regularly and apply lubrication. They should wipe off any debris or dust. Then they should apply some lubricant to minimize friction and reduce rail wear.

Second, regularly inspect and tighten the machine parts. The moving components in the JD6090L CNC router include the couplings, motors, belts, carving pipes, and brackets. Check them at least once every 2 weeks, especially if the machine cuts harder materials like wood.

Third, ensure the router's working environment is well-ventilated and dust-free. Locate the machine in a place with strong air flow and away from dust paths. This tip reduces the need for frequent cleaning and keeps the device functioning longer.

Fourth, create a maintenance schedule and stick to it. The schedule should include the regular inspection of replacing parts, lubrication, cleaning, and other support tasks. Finally, calibrate the CNC router every time the user changes material to improve cutting quality. Get the user manual for the recommended calibration steps.

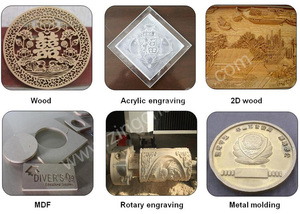

Here are some typical usage scenarios of the JD6090L CNC router machine:

Several factors need to be considered before purchasing the JD6090L CNC router, including:

Factory work demand analysis

First, buyers should make a detailed analysis of their work demand. Make a list of the materials, shapes, and sizes they'll be dealing with. This includes, but isn't limited to, analyzing the level of precision and intricacy required for their projects, as well as the expected workload and operating time.

Compatible material

The JD6090 CNC router can be used on different materials, ranging from wood and foam to metal and glass. However, not every machine in the product line can be used on these materials. For example, a router with a straight shaft will not be able to work on metals like aluminum, copper, etc. A job that involves working with metals will require a machine with a spindle that can work with metal or one with a laser attachment.

Work area and axis travel

Customers will need to consider if the work area and axis travel of the chosen machine will suffice for their projects. Generally, the JD6090 CNC has a large work area, making it possible for large materials to be worked on despite having limited space. The axis also move up to 60 cm and 90 cm, allowing great flexibility for vertical and horizontal movements.

Spindle power

The complexity of a project often depends on the spindle power of the CNC machine. Stronger and more powerful spindles can work on tougher and denser materials, such as hardwoods or metal, at greater speeds.

Precision requirement

The JD6090 CNC router achieves a certain degree of accuracy, with its engraving exceeding 0.05mm. However, each project has different requirements in terms of precision. Hence, buyers must select a machine that meets the project's demands to achieve the desired end result.

Software compatibility

A JD6090 CNC machine must be compatible with the same software as the other machines in the factory. To guarantee a seamless integration and functioning of the entire assembly line, it will be critical to selecting a machine that can be controlled by the same design and operation software as the others are.

Q: What software does a CNC router use?

A: CNC routers are typically programmed using CAD/CAM software. The design is created in CAD and then converted into toolpaths based on the design in CAM software. The toolpaths are then uploaded to the CNC machine for routing.

Q: What materials can a CNC router cut?

A: CNC routers are capable of cutting a range of materials. Common materials include wood, composites, plastic, PVC, foam, aluminum, brass, and acrylic. Each router may have limitations based on its size, power, and tooling.

Q: What is the difference between a CNC router and a CNC machine?

A: A CNC router is a type of CNC machine. CNC (Computer Numerical Control) machines also include CNC mills, lathes, plasma cutters, and laser cutters. CNC machines are controlled by computers to automate cutting and shaping processes precisely.

Q: How thick can a CNC router cut?

A: The cutting thickness capacity of a CNC router mostly depends on its design. While a typical CNC router can cut 4 to 6 inches (100 to 150 mm) thick solid materials like wood and foam, high-precision, high-power CNC routers can cut 10 inches or more of solid materials.