(28044 products available)

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

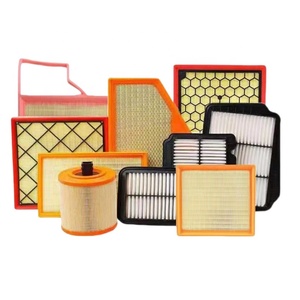

Engine Air Filters

Like other air filters, the Japan air filter also comprises fabrics, foam, and screen filter types. The Engine Air Filter removes dirt and debris from the air before it goes into the engine. Japan automotive air filters are known for their durability and high quality. For instance, Sakura filters, a well-known brand in Japan, produces filters with strength and performance in mind, and they are made from high-quality raw materials and have high dirt removal efficiency. They are also used for a long time. Engine air filters enhance performance and fuel efficiency.

Cabin Air Filters

Cabin air filters purify the air that goes into the car cabins. They trap dust, pollen, and other pollutants, ensuring passengers breathe clean air. Japan filters are widely used in automobiles because they can filter out even the smallest particles. This adds extra comfort and safety.

Oil Filters

Oil filters remove contaminants from the engine oil, ensuring proper lubrication. Some of the high-quality oil filters made in Japan include Denso filters and Sakura filters. With the removal of the debris from the oil, there is less wear and tear of the engine parts, therefore, giving japanese oil filter users an assured extension of engine life. They assure optimal performance and a reduction in harmful emissions.

Fuel Filters

Fuel filters eliminate impurities from gasoline or diesel before reaching the engine. Japanese fuel filters are recognized for precision and reliability. They ensure only clean fuel enters the engine, boosting performance and preventing damage. This is because dirty fuel can cause clogs and other detrimental effects.

Transmission Filters

Transmission filters remove contaminants from the transmission fluid, protecting vital components. This way, people who use japanese transmission filters benefit from enhanced filtration that ensures smooth gear shifts and prolongs the lifespan of their vehicles. Filters made in Japan are great for safeguarding the transmission system and reducing the risk of costly repairs.

Sakura Filters

Sakura filters are renowned for producing high-quality air filters. It has over 50 years of automotive experience and sources raw materials locally and internationally to manufacture filters.

Denso filters

Denso is another trusted japanese air filter brand that offers a wide range of air filters, including engine, cabin, oil, and fuel filters. The filters are built with advanced technology, and attention to detail assures their commitment to quality and reliability.

Aisin

Aisin is another famous name among air filter manufacturers in Japan. They leverage their extensive automotive expertise to manufacture filters that enhance vehicle performance.

Automotive Industry

Japan air filters are a preferred choice for many auto manufacturers. They are used in new cars and aftermarket replacements due to their durability and quality.

Commercial Vehicles

Air filters are used in trucks, buses, and other heavy machinery made in Japan to improve them and reduce maintenance costs.

Manufacturing and Heavy Machinery

Cabin air filters are used in construction, mining, and agricultural equipment made in Japan to protect operators and ensure an optimal working environment.

Motorcycles and Recreational Vehicles

Air filters are employed in bikes, RVs, and marine engines to ensure peak performance in all recreational activities.

When stocking air filters for customers, it is important to consider several factors. First, one must know the filter type preferred by ones customers and the materials used to make them. The customers' vehicles' make, model, and year should also be considered.

Then one should ensure that the filters to buy have OEM numbers corresponding to the stock numbers of the automobile manufacturers to ensure proper installation and guarantee vehicle manufacturers' retention of warranty.

Another important factor to consider is the pricing of the filters. One should get the best deal but ensure that the quality is not compromised. However, if the target market is professional mechanics, then one should stock the products that manufacturers use and those that offer superior performance, including high-efficiency variants for off-road or heavy-duty applications.

One should also stock disposable filters for customers who like to do single vehicle maintenance and replace it only. However, for environmentally conscious clients or those who prefer long-term solutions, quality reusable air filters that can be cleaned and re-oiled should be catered for.

Traditionally, air filters in Japan, made of paper, were small in size and had a high airflow. One can get ones customers who are interested in such products and stock sufficient quantities to satisfy the market demands. One should also stay informed about new filter technologies, such as those with pleated designs or incorporating advanced materials like activated carbon, to cater to customers seeking improved filtration efficiency.

Finally, one should consider logistical factors like lead times, shipping costs, and minimum order quantities to ensure timely restocking. By carefully considering these factors, one can build a profitable and customer-focused inventory of air filters.

Filter Media

Japan air filters use filter media, which is the primary dust capturing material, traditionally made of paper. Some recent ones are also made of synthetic materials, which are more environmentally friendly. Besides, they have high dust trapping efficiency. OEM paper air filters are made from high-quality filter paper bytrained and employing advanced technology by careful selection of the material and the manufacturing process. These materials ensure the filter traps as much dirt as possible while allowing the right amount of air to pass through.

Foam Filters

Foam filters consist of layers of foam and are used where high filtration efficiency is required, such as in off-road vehicles. They can be cleaned and reused, making them a practical choice for many users. The foam is chosen for its ability to capture large particles while still allowing good airflow.

Screens and Metal Mesh Filters

Metal mesh filters have strands of wire or metal brought together to form a mesh. Like foam, they can be washed and reused, providing a long-lasting solution for users. These are often used in industrial applications or heavy-duty vehicles, where durability is key. The screens are manufactured using strong and sturdy materials to prevent breakage and provide long service life.

Pleated Design

Many air filters use a pleated design to increase the surface area of the filter media. This allows more dirt to be trapped without restricting airflow. The pleats are carefully shaped and positioned to ensure optimal performance. Pleated filters are preferred where space is a concern or higher filtration efficiency is required.

Cabin Filters with Activated Carbon

Filters are made with activated carbon similar to those that filter out harmful gases, smoke, and bad odors in car cabins. These filters have a layer of activated carbon between or on top of the filter media layers. The carbon absorbs pollutants, improving the air quality inside the vehicle. Japanese manufacturers using durable charcoal materials for filtration guarantee effectiveness and a longer life for cabin air filters.

Sealing and Frame Construction

Japanese air filters are known for their strong frames and sealing methods, ensuring a snug fit within the housing. This prevents unfiltered air from bypassing the filter. The frames are constructed from robust materials, ensuring longevity and easy installation. Advanced sealing techniques, like polyurethane or rubber gaskets, enhance compatibility and reduce leaks, contributing to better engine protection.

Increased Engine Protection

Just like any other air filter, a Japan air filter protects the engine from harmful particles such as dust, pollen, and debris, preventing mechanical breakdown. For example, oil filters made in Japan have high filtration efficiency. They can remove contaminants and impurities from oil, preventing them from circulating and causing wear to engine parts. This ensures that only clean oil lubricates the engine. This prolongs the lifespan of the engine, and users do not need to worry about expensive repairs or replacements.

Improved Fuel Efficiency

Cabin air filters that are clean allow for better air intake into the engine, improving the process of combustion. When air filters are clean, the amount of fuel that needs to be consumed to achieve maximum work ability is reduced. In newer cars, airfilters can improve fuel efficiency by close to 10%. When combustion is efficient, there is no wasting of fuel, hence maximum exploitation of every dollar spent on fuel.

Enhanced Air Quality

Most japanese cabin air filters have activated charcoal in them, which purifies the air brought into the vehicle by the air conditioner and heater. This minimizes irritants such as pollen, allergens, and harmful fumes, hence cleaning the air, which is good for everyone's health. Using air filters that are regularly maintained helps occupants breathe easier and reduces the risk of respiratory problems. This is more beneficial to those with allergies or asthma.

Reduction of Emissions

By filtering out impurities and ensuring that only clean air enters the engine, air filters contribute to more complete fuel combustion. With more complete combustion, emissions of harmful pollutants like carbon monoxide, nitrogen oxides, and particulate matter are reduced. This is very important for the environment and even for the users of the vehicles, since less emission means cleaner air to breathe and less risk of contributing to air pollution.

Lower Maintenance Costs

In China, a transmission filter is expensive to replace, and it's lifetime is very long, especially when it's quality and made from strong materials like metal mesh or paper, and it can withstand high pressure and flow rate. By keeping contaminants out of critical engine parts, air filters reduce wear and tear on components. This means fewer repairs and longer intervals between mandatory maintenance. Overall, air filters pay for themselves by preventing costly repairs and making vehicle maintenance more manageable.

Regular replacement not only improves air quality but also boosts engine performance and fuel efficiency, hence saving the occupant benefits. Air filters in Japanese cars should be replaced or cleaned at least every 12,000 to 15,000 kilometers or annually. However, the replacement period can vary depending on driving conditions, such as dust, humidity, or heavy traffic, which increase the need for more frequent changes of air filters. It's always good to check the owner's manual for specific recommendations based on the vehicle's needs.

There are, indeed, reusable air filters that can be cleaned and re-oiled, making them a lifetime product. The reusable air filters allow drivers to clean and reinstall them several times, making them a cost-effective and environmentally friendly option. However, an efficient, high-quality disposable filter should not have its performance compromised by a reusable filter.

The durability of Japanese air filters comes from the quality materials they are manufactured with, such as synthetic fibers, metal mesh, and foam, which are resistant to wear, can handle various environmental conditions, and support heavy filtration. Filters like Denso filters have been invented and manufactured employing advanced technology, techniques, and skills that guarantee their durability. Moreover, stringent quality control processes ensure that only the best filters reach the market, enhancing their reputation for durability.