(80 products available)

The IOL hook, a surgical tool for cataract surgery, is used to place intraocular lenses (IOLs) in the eye. There are different kinds of IOL hooks, like the traditional and the advanced ones. Each kind has different features and benefits that help eye surgeons do their job well.

IOL hooks are surgical tools used to implant intraocular lenses. They come in various designs to meet the needs of different eye surgeons and procedures. Different IOL hooks are used for different IOL implantation techniques. Their diverse designs help make sure the IOLs are implanted accurately and securely in patients with different eye conditions.

Standard IOL Hook

Standard IOL hooks are shaped like a J and have a tiny loop at the end. These loops grab the IOL and help place it in the eye. They are strong and precise, making them perfect for everyday lens implantation.

Micro IOL Hook

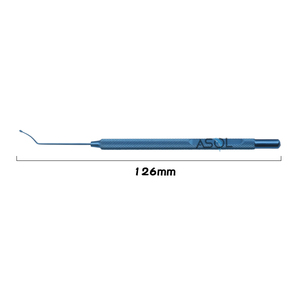

Micro IOL hooks are smaller than standard ones. They are about 5 mm long and have fine tips. These hooks can be used with tiny lenses or in situations where space is limited. They allow surgeons to act accurately in delicate eye operations.

Optical IOL Hook

Optical IOL hooks have curved tips that fit well on the lenses. These hooks reduce the chance of damage during surgery. They help surgeons grip the IOL firmly and place it correctly in the eye.

Multifocal IOL Hook

Multifocal IOL hooks are designed for complex multifocal lenses, which allow people to see well at different distances. These hooks are made to handle and insert these complicated IOLs, ensuring they are placed correctly and work well for the patient.

Adjustable IOL Hook

Adjustable IOL hooks can change their shape. They help with IOLs that change focus using light. These hooks are useful for placing these special lenses in the eye. They allow surgeons to adjust the grip on the lens as needed during surgery.

Anti-Static IOL Hook

Anti-static IOL hooks are designed to reduce static electricity. Static can cause IOLs to stick together or move unexpectedly. Anti-static hooks help prevent this problem, making it safer to handle and implant lenses.

Cataract Surgery

IOL hooks are essential in cataract surgery when the natural lens is replaced with an intraocular lens. The hooks help to insert and position the IOL lens correctly so that it functions well and does not cause damage to the eye. The hooks secure the IOL during the operation, ensuring it is placed where it should be in the eye. This makes them an important part of cataract surgery since they assist in the optimal placement of lenses for patients with cataracts.

Glaucoma Surgery

In surgeries to treat glaucoma, IOL hooks may be used to position drainage devices or shunts within the eye. These devices help lower eye pressure by allowing excess fluid to drain out. Using IOL hooks during glaucoma surgery ensures that drainage devices are accurately implanted and properly work to reduce eye pressure. This is important for the success of glaucoma procedures because it keeps the drainage devices from being wrongly placed, which could cause them not to work correctly or harm the eye.

Trauma Repair

When the eye has been injured and there is damage to its structures, IOL hooks can assist in fixing it. Hooks may be used to stabilize damaged lenses, secure artificial lenses or assist in reattaching retinal tissues. During such traumatic cases where precision is vital for healing, IOL hooks help surgeons carefully repair inner ocular injuries and restore vision. The use of these tools in trauma repair surgeries demonstrates their importance when dealing with complex eye injuries that require careful handling.

Research and Development

IOL hooks are also used in laboratory settings and during research activities related to developing new intraocular lenses or surgical techniques. Scientists can manipulate lens models using these tools while testing them on eye samples. In such a case, IOL hooks support researchers in studying how different lens designs might behave when implanted in real eyes. Their role in research highlights the versatility of IOL hooks, which aid the advancement of knowledge about improving eye surgery methods.

Material Selection:

Choose IOL hooks made of high-quality materials like medical-grade stainless steel or polymers. These materials provide the necessary strength, flexibility, and biocompatibility for safe implantation and manipulation within the eye. For example, polymer IOL hooks can have properties like reduced friction for smoother lens handling or the ability to change shape with temperature to adapt to different eye structures.

Design Considerations:

Design IOL hooks with features such as a tapered or smooth tip to facilitate gentle insertion and minimize trauma to the eye. Incorporate ergonomics into the handle design, such as curved or textured surfaces, to improve the surgeon's grip and reduce hand fatigue during lengthy procedures. Adding a stop feature near the hook's tip can help prevent unintended advancement of the hook and improve control.

Functionality Testing:

Evaluate the performance of IOL hooks through laboratory testing, such as measuring the forces required for smooth lens manipulation or the durability of the hook during repeated insertions and withdrawals. Perform benchmarks on the hook's ability to slip or catch on rough surfaces to ensure reliability in delicate surgical environments. Consider conducting user testing by soliciting feedback from ophthalmic surgeons on the hook's usability, visibility in the surgical field, and overall satisfaction.

Regulatory Compliance:

Obtain the necessary approvals from regulatory bodies, such as the U.S. Food and Drug Administration (FDA) or the European Medicines Agency (EMA), before bringing the IOL hook to market. This may involve providing data on the hook's safety and effectiveness, manufacturing processes, and quality control measures. Also, engage with the regulatory agencies early in the product development process to understand the requirements for medical device approval and ensure compliance.

Manufacturing Considerations:

Establish a reliable manufacturing process that can produce IOL hooks with consistent quality and precision. Implement strict quality control measures, such as inspection of material properties, dimensional accuracy of hook features, and verification of surface finish. Consider using advanced manufacturing techniques, such as laser cutting or micro-molding, to achieve intricate designs and fine details on the hooks. Ensure that the manufacturing environment meets cleanliness standards to minimize the risk of contamination of the surgical instruments.

Q1: What is an IOL hook used for?

A1: IOL hooks are utilized during cataract surgery to implant intraocular lenses (IOLs) into the eye.

Q2: How many IOL hooks are there?

A2: There are various kinds of IOL hooks, such as silicone hooks, malleable hooks, rigid hooks, micro hooks, and lighted hooks.

Q3: What are the benefits of using IOL hooks?

A3: The advantages of using IOL hooks include improved precision in lens placement, minimal trauma to ocular tissues, and enhanced visibility of the surgical field.

Q4: What material is usually used to make IOL hooks?

A4: Most IOL hooks are made from high-quality materials like stainless steel and plastics that ensure they are strong enough to be used in delicate eye surgeries.

Q5: How can one ensure the quality of IOL hooks?

A5: To ensure the quality of IOL hooks, one should look for products that meet international standards and have certifications such as CE and ISO.