(8682 products available)

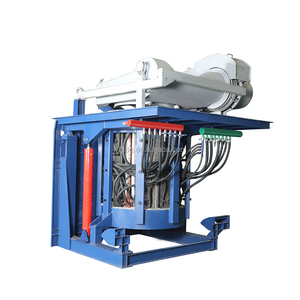

An electric resistance furnace, also known as an electric arc furnace, is essential to any foundry. Its function is to melt metal using electricity as its main power source. An electric resistance heating furnace can come in various shapes and sizes, each catering to a specific industry or requirement. With technological advancements, induction electric furnaces now possess the capability to melt down aluminum at rates of up to 10000kg per hour.

The specifications of industrial electric resistance heating furnaces for sale vary depending on the specific type and purpose of the furnace, as well as the manufacturer's design. Several key specifications need to be noted to help business buyers understand the details of the electric resistance furnace.

Generally speaking, the performance parameters of electric resistance heating furnaces will vary according to the exact type (such as box-type electric resistance heating furnaces, which are usually used for annealing, quenching, universal use, etc.), and the purpose (for example, the electric resistance heating furnaces for metallurgy are more significant, and the one for the machinery industry are wider) also the specific application fields. Businesses need to choose electric heating resistance furnaces according to their particular production needs and technical requirements.

Regular maintenance helps ensure safety, reliability, and operational efficiency. Here are some general maintenance suggestions:

Industrial electric furnaces are used in various industries and fields. Some of the common use areas are as follows:

Metallurgical Industry:

Industrial electric resistance furnaces are mainly used for smelting and refining non-ferrous metals, iron and alloys. According to the industrial electric furnace suppliers, about 80% of induction electric furnaces are used for steel melting and other metals.

Metal Heat Treatment:

Heat treatment mainly includes tempering, quenching, normalizing, annealing and carburizing. An electric resistance furnace is used to heat the metal at a very high temperature so that it changes its structure and increases its durability. About 20% of electric furnaces are used for the heat treatment of metals. This is a very common but also vital use of electric resistance furnaces in industrial settings.

Ceramics and Glass Industry:

An electric resistance heating element furnace can help in the production of ceramic and glass products. The materials are usually fragile and difficult to work with. The use of industrial electric resistance furnaces allows for these materials to be heated carefully or to molten states. Once cooled, they will solidify and become durable and sturdy.

Construction Industry:

The construction industry also uses electric resistance furnaces to produce steel, aluminum and other alloys. These materials are used as the foundation in the manufacture of windows, frames, doors and other building materials.

Jewelry and Watch Making:

Jewelry and watch making require high-precision work. By using electric resistance furnaces, workers can create small intricate parts and pieces. These will have the strength to stand the test of time.

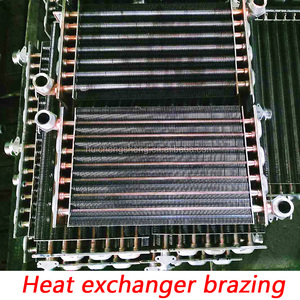

Automotive and Aerospace Industries:

Industrial electric resistance furnaces are used in the automotive and aerospace fields to make critical alloys and components. Induction and resistance heating are the mainstream technologies in the automotive industry for welding, heat treatment and forming.

Choosing an electric resistance furnace requires understanding the purpose, specifications, and features of the available options.

Application requirements analysis

Users should first analyze their application requirements. Consider the types of materials to be processed, their sizes, weights, and temperature requirements. Also, think about the heating methods and atmospheres of the processes. By a thorough analysis, users can determine the suitable industrial electric resistance furnace types for their applications.

Furnace types

Users can choose suitable industrial electric resistance furnace types according to their application needs. For example, a box furnace or furnace with a workbench may be preferred for heat treatment. An induction furnace may be suitable for smelting and casting an electric arc for welding.

Specifications

Users should pay attention to the specifications of the furnace. The volume and capacity of the furnace should meet the production needs. The temperature range and heating rate should reach the required processing temperatures and speeds. The energy efficiency of the furnace is also crucial. Higher energy efficiency can save operating costs for businesses.

Additional features

In addition to the above, users can consider further functions of the furnace, such as the atmosphere control. Some industrial electric resistance furnaces offer the ability to control the processing atmosphere, which is essential for particular reactions and transformations. Furthermore, users may be interested in the accessibility and maintainability of the equipment. Easy maintenance and cleaning can improve production efficiency and equipment uptime.

Safety and environmental standards

Users should select industrial electric resistance furnaces complying with safety and environmental standards. These furnaces can protect operators from various hazards, such as high temperatures, toxic gas emissions, and electrical hazards. Moreover, environmental monitoring devices can reduce the environmental impact of the industrial site.

Q: What are the three basic components of an electric furnace?

A: The three basic components of an electric resistance heating furnace are the heat generation system, heat transfer system, and insulated storage system.

Q: How do users determine the size of an electric arc furnace?

A: Electric arc furnace size can be determined by the plant capacity in tons, the chemical composition of the electric resistance furnace materials to be handled, including their size and purity, the desired power input per ton of material, the voltage requirement of the electrical supply system, and the installation requirements, including site constraints and safety regulations.

Q: What is the future of electric resistance furnaces in the industry?

A: The use of electric resistance heating furnaces is likely to increase in the future, given the global decentralization of electricity supply and increasing demand for high-precision control systems. Additionally, the role of electric resistance heat-generating furnaces in supplying the industry's critical needs is likely to support rapid market expansion.