(30799 products available)

Ignition ceramics are materials used in igniters or ignition systems. They can be ceramic insulators or substrates that help generate heat or spark to start combustion. Various ignition ceramics are used in igniters, each with unique properties and advantages. Here are some common ignition ceramics types:

Alumina ceramics

Alumina ceramic igniters are among the most common and widely used ignition ceramics. They are known for their excellent electrical insulation properties and high-temperature resistance. Alumina igniters are often used in gas burners, industrial furnaces, and other applications requiring reliable ignition.

Zirconia ceramics

Zirconia ceramics igniters have higher toughness and thermal shock resistance than alumina ceramics. They are suitable for applications with rapid temperature changes or high mechanical stress. Zirconia igniters are commonly used in gas turbines, aerospace engines, and other demanding environments.

Silicon carbide ceramics

Silicon carbide (SiC) ceramics igniters have high thermal conductivity, hardness, and wear resistance. SiC ceramics are suitable for high-temperature and corrosive environments. They are often used in coal gasification, biomass gasifiers, and other clean energy technologies.

Piezoelectric ceramics

Piezoelectric ceramics igniters use the piezoelectric effect of ceramics to convert mechanical energy into electrical energy. It creates a high-voltage spark to ignite. This type of igniter does not need electricity and has high reliability and safety. Piezoelectric ceramics are commonly used in gas stoves, camping stoves, and fireworks igniters.

High-temperature ceramics

High-temperature ceramics igniters are designed for extreme environments where traditional ceramics may not withstand. These igniters use materials such as mullite, silicon nitride, or composite ceramics to improve oxidation resistance, thermal stability, and mechanical strength. They are often used in aerospace, defense, and high-temperature industrial processes.

General Design Considerations:

When designing ignition ceramics, the following factors are considered:

Performance Requirements: Ignition ceramics are designed to meet specific performance requirements, such as fast and reliable ignition, high temperature resistance, and chemical stability. These requirements guide the selection of materials, shapes, and surface features.

Material Selection: The choice of materials for ignition ceramics depends on factors such as temperature range, compatibility with fuels or gases, and mechanical strength. Common materials include alumina, zirconia, and silicon nitride ceramics, which offer good thermal and chemical resistance.

Manufacturing Processes: The design of ignition ceramics considers the manufacturing processes used to make them. These processes may involve shaping ceramic powders, drying, and firing them at high temperatures to achieve the desired properties. Designing for manufacturability ensures cost-effectiveness and production efficiency.

Aesthetics and Ergonomics:

Aesthetics: While performance is critical, the visual appearance of ignition ceramics can also be considered. This may involve selecting colors, surface textures, and finishes that enhance the product's overall look.

Ergonomics: The design of ignition ceramics takes into account user comfort and ease of use. This includes designing shapes that are easy to handle, operate, and maintain, ensuring the product is user-friendly.

Design Elements:

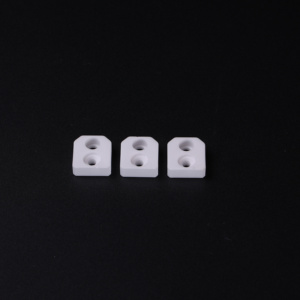

Shapes and Structures: Ignition ceramics can have various shapes, such as cylindrical, disc-like, or complex geometric forms. These shapes are designed to fit specific ignition system requirements.

Surface Features: The surface of ignition ceramics may have special features, such as microstructured textures or coatings, to enhance ignition performance and catalyst activity.

Electrical Connections: Some ignition ceramics require electrical connections, which are designed to be convenient and reliable to ensure proper operation of the ignition system.

Ignition ceramics have many applications in different industries. Their ability to withstand high temperatures, corrosion resistance, and durability make them very useful in many industrial processes and commercial applications.

Industrial applications

Ignition ceramics are used in industrial applications. They are used to make furnace linings, kiln components, and heat exchangers. Ignition ceramics are used to make spark plugs for internal combustion engines in automotive and aerospace industries. They are also used to make gas turbine blades, engine components, and combustion chamber linings. Ignition ceramics are used as insulators in sensors and electronic devices. They enable accurate temperature and pressure measurements in automotive engines, industrial processes, and aerospace systems. In oil and gas exploration, ignition ceramics are used to make drill bits, well logging tools, and downhole equipment. The ignition ceramics can withstand harsh conditions and high temperatures in deep underground.

Catalytic converters

Ignition ceramics are used in catalytic converters for automotive and industrial applications. The ceramic materials provide a substrate for catalytic activity, helping to convert harmful emissions into harmless gases. This application is crucial for reducing air pollution and meeting emission standards.

Medical devices

Ignition ceramics are used in several medical devices and applications. Ceramic materials are biocompatible, which means they can safely interact with biological tissues. This property makes ignition ceramics suitable for implants, such as dental crowns and joint replacements. Ceramics can bond with bone tissue, providing a stable and durable solution for repairing or replacing damaged body parts.

Electrical insulation

Ignition ceramics are used as electrical insulators in high-voltage applications. Ceramics can withstand high electric fields and prevent short circuits, making them suitable for power transmission, transformers, and other electrical equipment.

Environmental applications

Ignition ceramics are used in environmental applications. They are used in waste treatment, air pollution control, and water purification systems. Ignition ceramics can provide corrosion-resistant liners for hazardous waste storage tanks and containers. They can also be used to make filters and membranes for water treatment.

Wholesale buyers need to consider these factors when choosing ignition ceramics for their target market.

Market Demand and Application Trends

Study the target market to determine the demand for ignition ceramics. What are the popular materials, designs, and applications? What do customers want? Focus on trends that will drive future sales.

Performance and Quality Standards

Select ignition ceramics that meet industry standards. They should have good strength, thermal shock resistance, and chemical stability. Choose high-quality ceramics from reputable suppliers. They will have a good reputation and increase customer trust.

Compliance with Regulations

Be aware of safety and environmental regulations for ignition ceramics. Comply with local and international standards. Choose ceramics that do not have harmful substances. They should be safe for customers and the environment.

Supply Chain and Logistics Considerations

Evaluate the supply chain for ignition ceramics. Choose suppliers who can deliver the products on time. Ensure they have the capacity to meet demand. Consider the packaging and shipping. Ensure the ceramics will not break during transportation.

Cost and Pricing Strategy

Calculate the cost of ignition ceramics, including production and transportation costs. Then, set a retail price that will be profitable. Also, consider discounts for bulk orders. Maintain a balance between cost and quality.

Collaboration with Suppliers

Work closely with suppliers of ignition ceramics. Share market insights with them. Then, collaborate to develop products that meet customer needs. Ask them to help with product education and marketing support.

Q1: What are the benefits of using ignition ceramics in energy applications?

A1: Ignition ceramics provide excellent corrosion resistance, thermal management, and reliability, which lead to enhanced performance and longevity in energy applications.

Q2: How can ignition ceramics improve battery technologies?

A2: Ignition ceramics can improve battery technologies by using them as solid-state electrolytes, separators, and electrode additives to increase conductivity, stabilize interfaces, and improve energy density.

Q3: What is the role of ignition ceramics in catalyst systems?

A3: Ignition ceramics are used in catalyst systems to serve as supports for catalysts, enhancing their mechanical strength, thermal stability, and resistance to poisoning and sintering.

Q4: What are some characteristics of ignition ceramic coatings?

A4: Ignition ceramic coatings offer superior wear resistance, thermal insulation, and protection against corrosion and oxidation, thus extending the life of coated components and improving their performance.

Q5: How do ignition ceramics contribute to the development of renewable energy technologies?

A5: Ignition ceramics play a vital role in renewable energy technologies by offering solutions for solar energy conversion, biomass energy utilization, and hydrogen production, thereby promoting the efficiency and sustainability of renewable energy technologies.