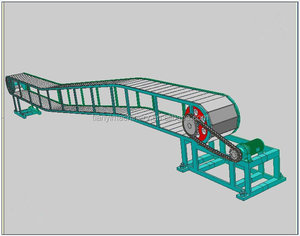

Introduction to Hot Chain Conveyors

A hot chain conveyor is an essential piece of equipment utilized in various industries for the transportation of hot materials. Reliable and efficient, these conveyors are engineered to withstand high temperatures, making them crucial for operations in sectors such as manufacturing, food processing, and metals. Understanding the features and benefits of hot chain conveyors can significantly enhance operational efficiency and safety in any industrial setting.

Types of Hot Chain Conveyors

Hot chain conveyors come in several types, each tailored for specific applications and materials:

- Enclosed Track Hot Chain Conveyors: Ideal for carrying hot items in a contained environment, minimizing exposure to external elements.

- Drag Chain Conveyors: Utilized in industries for moving heavier, bulk materials that need high-temperature resistance.

- Plastic Chain Conveyors: Designed for lighter loads, these conveyors offer flexibility while maintaining durability against heat.

- Slat Chain Conveyors: Suitable for handling hot products that require a robust support structure, commonly seen in food production lines.

Features and Functionality of Hot Chain Conveyors

Hot chain conveyors are packed with features that enhance their functionality and efficiency:

- High-Temperature Resistance: Engineered from materials that endure extreme heat, ensuring longevity and reliability.

- Robust Design: Built with heavy-duty materials that provide strength and durability, minimizing the risk of breakdowns.

- Modular System: Allows for flexible configurations, enabling businesses to adapt to changing production requirements.

- Low Maintenance: Designed for easy upkeep, hot chain conveyors minimize downtime and operational disruption.

- Noise Reduction: Many models incorporate features that reduce operational noise, providing a better working environment.

Applications of Hot Chain Conveyors

Hot chain conveyors find widespread applications across various sectors, demonstrating their versatility:

- Metal Processing: Used for transporting hot metals in foundries and forging facilities, ensuring safe and efficient handling.

- Food & Beverage Industry: Crucial for moving cooked products or items that are heated during the production process, maintaining quality and safety standards.

- Ceramics and Glass Manufacturing: Ideal for conveying items that are processed at high temperatures, offering protection against damage.

- Chemical Industries: Suitable for transporting materials that require elevated temperatures to remain in a liquid state during processing.

Advantages of Hot Chain Conveyors

Hot chain conveyors present numerous advantages that make them a valuable asset across industrial operations:

- Increased Efficiency: Streamlining the movement of hot materials helps to optimize production processes and reduce operational bottlenecks.

- Enhanced Safety: The design and materials used mitigate risks associated with handling hot loads, ensuring safer workplace conditions.

- Cost-Effective Operations: With reduced maintenance needs and prolonged service life, hot chain conveyors are economically beneficial for businesses.

- Improved Product Handling: Their design ensures that products are transported securely, minimizing the chances of damage or loss during transit.