(3475 products available)

High-rpm motors for air coolers come in various forms. Each motor type caters to distinct requirements, presenting varied operational attributes. Understanding the various kinds ensures one picks a motor that best fulfills the air cooler's demands for efficiency and functionality. Below are the types of high-rpm motors for air coolers.

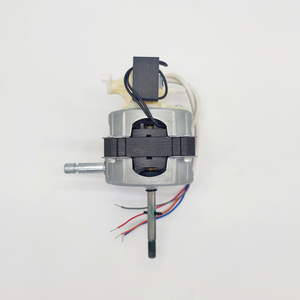

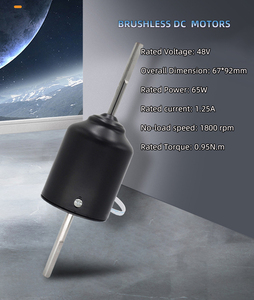

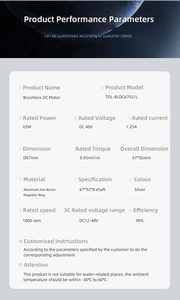

Brushless DC motors have electronic components and merely not mechanical brushes. The absence of brushes lowers friction, promoting efficiency and a longer lifespan. These motors have high rpm and provide variable speed control, crucial for air coolers adapting to different environmental conditions.

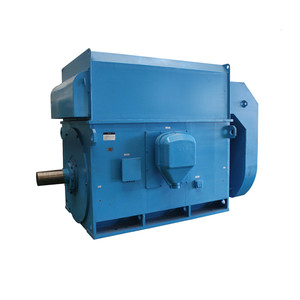

Induction motors, or AC motors, are widely used due to air coolers' robustness and minimal maintenance. These motors operate at high speeds by turning the rotor through electromagnetic induction. Induction motors are better for air coolers in commercial and industrial settings since they provide constant airflow and high performance.

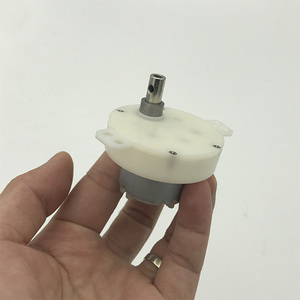

Stepper motors rotate in precise increments or steps. There are high-speed stepper motors that can be utilized in air coolers for precise blower or fan control. These motors give the right airflow patterns, essential for applications requiring varying air speeds.

Brush DC motors utilize mechanical brushes for energy transfer. Although these motors have lower efficiency than brushless motors, they offer simple speed control through voltage variation. Brush DC motors are found in portable or smaller air coolers where compactness and low power consumption are primary concerns.

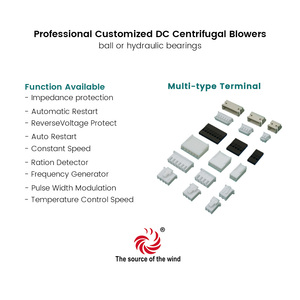

High-rpm fans or motors for air coolers find broad utilizations across numerous sectors. Each sector utilizes the motors' efficiencies and capabilities, thus enhancing cooling solutions to meet specific needs. Below are industry applications of high-rpm motors for air coolers.

High-rpm motors are integral to air coolers in industrial manufacturing. This is especially true in processes needing cooling after welding, casting, or machining. The rapid airflow maintains temperature control to enhance product quality and worker safety.

Highrpm motor air coolers in the automotive realm prevent overheating in vehicles and engine compartments. The electric fans aid in heat dissipation, thus preventing engine failure, improving performance, especially in adverse weather conditions. Therefore, this ensures smooth functioning.

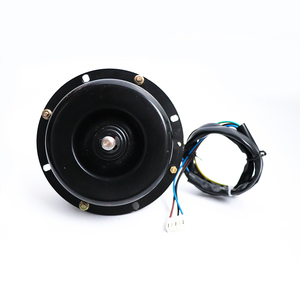

In the electronics field, high-rpm motor coolers dissipate heat from sensitive components like servers, GPUs, and CPUs. Maintaining optimal temperatures boosts system performance and prevents hardware failure. Their compact design ensures appropriate cooling even in limited space.

Air coolers with high-rpm motors for agriculture are used in greenhouses, livestock buildings, and during crop drying to moderate temperatures. This keeps plants and animals in a conducive environment, therefore enhancing optimal growth. It also helps overcome seasonal constraints and boosts production capacity.

In HVAC systems, high-rpm motors for air coolers drive fans and blowers, facilitating air circulation, heat exchange, and temperature regulation in residential, commercial, and industrial establishments. Their efficiency contributes to better energy-saving cooling systems, reducing dependence on electric bills, and enhancing indoor comfort.

A high-rpm motor for air coolers is engineered to provide effective and reliable cooling. Understanding the specifications and features helps evaluate the motor's performance and capacity and its effectiveness in different cooling applications. Below areproduct specifications and features of high RPM motor for air cooler.

High Rotational Speeds

High-RPM motors offer over 3000 RPM, providing efficient airflow and heat dissipation in air coolers. The high speed enables the circulation of air rapidly, improving cooling effectiveness and making it ideal for diverse environments and applications.

Efficiency

High-RPM motors are efficient and minimize energy consumption while providing optimal airflow. Air coolers can operate for longer periods without excessive energy, especially with brushless DC or EC motors, making them cost-effective and environmentally friendly.

Compact Design

High RPM motors generally have a compact design, which makes them easy to install, especially in space-restricted air cooler systems. The small size allows portable air coolers to be lightweight and easy to carry.

Durability

High RPM motors are durable, are IP-rated for dust and water resistance, and can work under harsh conditions of any ambient temperature. These are crucial for outdoor and industrial applications since they endure temperature differentials, humidity, and exposure to elements without losing performance.

Speed Control

The motor enables speed variation, allowing users to adjust cooling levels according to the specific needs. This versatility ensures that air coolers can offer personalized comfort and efficiency across different environments and applications.

Selecting the right highrpm motor for an air cooler requires careful consideration of various factors. These factors impact the motor's performance, efficiency, and compatibility with cooling systems. Below are some key factors to consider when choosing a highrpm motor for air coolers.

Consider the electrical power input that the motor necessitates to operate efficiently. One should assess the existing electrical systems available in their air cooler. It will ensure that the motor complies with the power availability to minimize complications. The power requirements directly affect the motor's performance and energy efficiency.

The specific motor type mainly determines the operational characteristics. Brushless DC motors offer higher efficiency and precise speed control, while AC induction motors provide continual high performance. One should determine the application requirements to select an ideal motor type for air coolers.

Environmental factors like temperature, humidity, and exposure to dust or moisture significantly affect motor performance and longevity. Induction motors are better for industrial settings with high temperatures and dust levels. They are durable and can handle extreme working temperatures without compromising their performance.

Consider the range of the motor's rotational speeds and its system requirements. Higher RPMs give greater airflow and cooling capacity but may cause excessive noise. Opt for motors with variable speed ranges to balance the requirements for optimal cooling without the unnecessary noise.

Assess the cooling needs of the space the motor will cool. In a large area, high RPM motors generate an adequate airflow to ensure desirable temperatures. Conversely, for smaller spaces, lower RPMs will be sufficient to offer the required cooling capability without overdoing it.

A1. High-RPM Motor air coolers use stainless steel, copper, aluminum, and high-grade electrical steel. Aluminum offers strength with a lighter body mass. Electrical steel enhances magnetic efficiency, therefore minimizing energy losses. Cooling fans utilize stainless steel for enhanced corrosion resistance to rudimentary and humid conditions.

A2. The motor diameter varies significantly based on the application and motor type. Small portable air coolers use motors with a diameter of fewer than 4 inches. Larger industrial air coolers use motors with a diameter of over 10 inches. The diameter depends on the required airflow and cooling capacity.

A3. To enhance the lifespan, regularly clean the motor components and check for wear. Proper lubrication reduces friction, and frequent examination for electrical damage and overheating is ideal. Protecting the cooler from extreme environmental conditions will minimize exposure to dust and moisture, thus increasing its longevity.

A4. Yes, high-rpm motors are energy efficient, especially brushless DC and electronically commuted motors. These motors provide effective airflow with minimal energy consumption. Induction motors are designed for efficiency. They maintain optimal cooling with less power reliance.

A5. The standard voltage varies with application and motor type. HighrMP motors used in industrial applications typically require voltages of 230AC. Portable and residential models prefer lower voltage of 12DC to 24DC for simple electrical system integration. The standard voltage ensures optimal motor performance.