(879 products available)

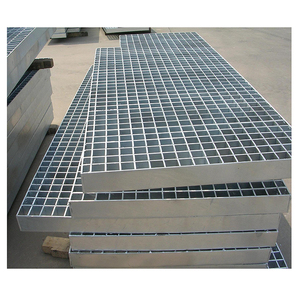

Steel grating is a popular load-bearing platform used in various industries. They are used in construction walkways, platforms, and other applications. Steel grating is a grid-like structure that allows light, air, and water to pass through. It is made up of longitudinal bearing bars and cross bars. They are widely used in industrial and commercial applications due to their durability, strength, and corrosion resistance. HDG steel gratings are hot-dip galvanized after fabrication to provide enhanced rust and corrosion resistance. Here are the different types:

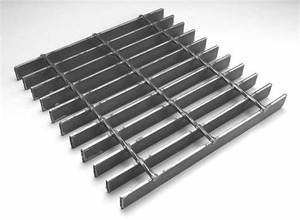

Bar Grating: This steel grating is constructed with parallel bars. It is available in various designs, such as welded, press-locked, or swage-locked. Bar steel grating is used in heavy-duty industrial applications. They offer excellent strength and ventilation. The design of this steel grating allows easy passage of light, air, and liquids while providing a robust walking surface.

Expanded Metal Grating: This steel grating is made from metal sheets. The sheets are cut and stretched to form a diamond-shaped pattern. This expanded metal grating is lightweight and offers high strength. They are used in applications that require drainage, airflow, and visibility. Examples include walkways, stair treads, and platforms.

Perforated Metal Grating: This type of steel grating is made from metal sheets. The sheets are punched with patterns of holes to create a grid-like structure. This grating is lightweight and offers high strength and rigidity. They are also slip-resistant. Perforated metal grating is used in applications that require light transmission, ventilation, and aesthetic appeal.

Fiberglass Reinforced Plastic (FRP) Grating: This steel grating is constructed with fiberglass composite materials. They are formed through pultrusion. This process involves creating continuous profiles of high-strength fiberglass reinforced with plastic. FRP grating is lightweight, anti-corrosive, and non-conductive. They are used in environments with high humidity and corrosive chemicals.

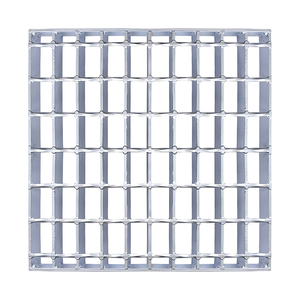

Rectangular and Square Grating: This type of steel grating is constructed with flat bearing and cross bars. They provide a modern aesthetic look. Rectangular and square gratings are lightweight and have high strength. They are used in pedestrian areas, driveways, and light industrial applications.

Steel grating has several applications in various industries, and its features offer practical solutions to different needs. Some functions include:

Walkways and Platforms

Steel grating provides safe and durable pedestrian walkways and industrial platforms. Their design allows easy drainage of water and debris, minimizing slip hazards and reducing maintenance efforts.

Flooring

They are widely used in industrial and commercial flooring applications, including factories, warehouses, parking garages, and commercial buildings. Steel floor grates offer high load-bearing capacity and excellent ventilation, making them suitable for high-traffic areas and environments where airflow and drainage are essential.

Cover for drains

Steel grates can be used as drain covers to protect people from falling into drains and prevent debris from clogging drainage systems. They allow water to flow freely while supporting heavy traffic above.

Heavy duty steel grating:

This type of steel grating is used for applications that require high strength and load-bearing capacity. It is commonly used in industrial environments, such as steel mills, foundries, and heavy machinery areas. This grating can handle heavy loads, wear and tear, and harsh conditions.

Decoration:

Steel grating can also be used for decorative purposes, such as in outdoor spaces, garden furniture, and architectural elements. Decorative steel grating adds an aesthetic appeal to functional properties, providing visual interest while maintaining strength and durability.

Benefits of Steel Grating

Steel grating offers several advantages that make it suitable for various applications in different industries. Some of these benefits include:

High load capacity: Steel grating is designed to withstand heavy loads and high traffic. It is ideal for applications in industrial environments and commercial settings.

Durability: Steel grating is made of steel, a material known for its durability and longevity. Steel grating can last for many years before requiring replacement or extensive maintenance.

Slip resistance: Steel grating surfaces are designed to be slip-resistant, ensuring the safety of pedestrians and workers in high-traffic and hazardous environments.

Ventilation: The open-grid structure of steel grating allows for air circulation, water flow, and light penetration. This is particularly beneficial in applications where ventilation and drainage are essential.

Low maintenance: Steel grating requires minimal maintenance due to its durable and corrosion-resistant properties. This can help reduce long-term maintenance costs and efforts.

Customizable: Steel grating can be manufactured in various sizes, shapes, and bar configurations to meet specific design requirements and load-bearing capacity.

Hdg steel gratings are utilized in various industries and applications, providing solutions for safety, visibility, and functionality. Here are some common usage scenarios:

Walkways and Pedestrian Paths

Hdg steel gratings are often used in walkways and pedestrian paths in industrial and commercial settings. They offer slip-resistant surfaces, ensuring the safety of pedestrians even in wet or oily conditions. The open-grid design allows for water runoff and reduces the risk of slipping.

Parking Decks

These steel plates are used in parking deck flooring systems. The grating allows drainage of water and chemicals, preventing pooling and reducing slip hazards. They also resist the corrosive effects of de-icing salts and chemicals used in winter maintenance.

Machine Platforms and Bases

Machine platforms and bases are constructed with hdg steel gratings. This is because they provide strong and stable support for heavy machinery. Their load-bearing capacity ensures the safe operation of machines. Additionally, the gratings allow airflow and reduce heat buildup in operating machines.

Bridges and Drain Covers

Hdg steel gratings are used in the construction of footbridges and vehicle bridges. They reduce the overall weight of the structure while maintaining strength and stability. Steel gratings improve visibility, making it safer for pedestrians and vehicles.

Additionally, they are used as drain covers. The steel construction supports heavy traffic loads and ensures safe access to drainage systems. The open-grid design prevents drain blockage by debris and facilitates water flow.

Rooftop Applications

Steel gratings are used for rooftop walkways, HVAC covers, and roof gardens. The lightweight nature of steel grating reduces structural load. The drainage properties of the gratings prevent water accumulation and potential damage to the rooftop. Additionally, they offer safe maintenance access and reduce slip hazards.

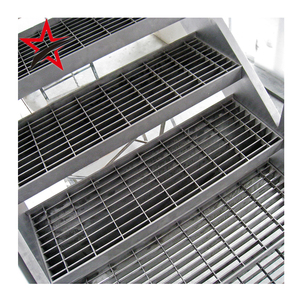

Stairs and Ramps

Hdg steel gratings are ideal for constructing stairs and ramps in industrial settings. They provide slip-resistant surfaces for safe navigation in high-traffic areas. The gratings facilitate light penetration and improve visibility. Additionally, they allow for natural ventilation and reduce wind resistance.

Choosing the right steel grating involves considering various factors to ensure it meets the intended application requirements. Here are some factors that wholesalers should consider when purchasing steel grating:

Understand the Application Requirements

Wholesalers should determine the specific requirements of their clients' applications. This includes load-bearing capacity, environmental conditions, and safety requirements. Steel grating used in walkways and platforms is ideal for high-traffic areas. On the other hand, steel grating used in drainage covers should be corrosion-resistant.

Consider Load-Bearing Capacity

Each type of steel grating has a different load-bearing capacity. Therefore, it is important to closely look at the specifications and select the one that meets the application requirements. Consider factors such as the spacing between support beams and the expected load per square meter.

Evaluate Environmental Conditions

Environmental conditions greatly influence the performance and durability of steel grating. For applications in corrosive environments, opt for galvanized or stainless steel grating. Such a type of grating offers the best protection against rust and corrosion. In high-temperature environments, choose a grating material with a high melting point.

Check Slip Resistance

Safety is a significant concern in most applications. Therefore, choose a slip-resistant steel grating to ensure optimum safety. Look for features such as serrated surfaces or welded non-slip bars. These features increase traction and reduce the risk of slipping, especially in wet or oily conditions.

Assess Ease of Installation and Maintenance

Choose a steel grating that is easy to install and maintain. Consider the welding and bolting options available. Also, consider the maintenance requirements over the steel grating lifespan. Furthermore, look for a grating type that is easy to clean and resistant to damage.

Customization Options

Some applications require customized solutions. Therefore, it is important to check the available customization options when purchasing steel grating. This includes custom sizes, finishes, and load-bearing patterns.

Certifications and Quality Standards

Ensure that the steel grating supplier adheres to the required quality standards and certifications. This guarantees the quality and performance of the products.

Q1: How is galvanized steel grating maintained?

A1: Galvanized steel grating requires minimal maintenance. Regular cleaning to remove debris and inspection for any signs of wear or corrosion is usually sufficient. In harsh environments, additional galvanizing may be considered to ensure longevity.

Q2: Can grating be customized?

A2: Yes, steel bar grating can be customized. Manufacturers offer various options for bar spacing, thickness, and overall dimensions. Some also provide choices for grating finishes, such as galvanization or powder coating.

Q3: What are the non-slip features of galvanized steel grating?

A3: Steel grating provides excellent slip resistance due to the open surface that allows water, oil, or other liquids to drain. Non-slip bars are also available, featuring a textured surface or raised patterns for enhanced traction in high-slip areas.

Q4: Is galvanized steel grating easy to install?

A4: Yes, galvanized steel grating is generally easy to install. It is lightweight and comes in prefabricated sections that can be secured using clips, bolts, or welding, depending on the application and design requirements.

Q5: What industries commonly use galvanized steel grating?