(2266 products available)

Hay rakes are agricultural tools used to gather and organize dried grass or hay into windrows for easy harvesting. Various types of hay rakes are designed to gather hay efficiently without damaging the crops.

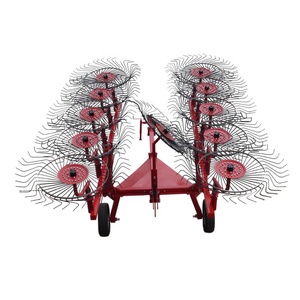

Wheel Hay Rake:

A wheel hay rake consists of a frame and a series of curved wheels with lightweight rims. As the rake is pulled through the field, the wheels rotate and scoop up the hay, forming windrows. Wheel hay rakes are gentle on the crop but may leave some scattered debris.

Stacker Rake:

Stacker rakes are designed to gather hay into stacks instead of windrows. They have a similar setup to a wheel hay rake but typically have more wheels and closer spacing between them. Stacker rakes also have a curved, tall frame. The additional wheels and curve allows the rake to gather the hay vertically into a stack. This type of hay rake is suitable for crops like alfalfa or clover that are grown in small, tight fields. Stacker rakes can also be modified to gather crops that are grown on larger fields by adding a gatherer apron that goes underneath the gatherer and pulls the crop up into the stack.

Disc Hay Rake:

Disc hay rakes have several small, scooping discs mounted on a frame. The discs rotate and scoop up the hay as the rake is pulled forward, depositing the hay into windrows. Disc hay rakes are more versatile and suitable for various soil and crop conditions.

Rotary Tedders:

A rotary tedder is different from a hay rake. It fluffs and turns the hay to speed up the drying process. Rotary tedders have a series of lightly curved arms that throw and spread out the hay. One or more spinning bowls usually hold the arms. Teether arms can be made of metal or plastic, and the number of arms and bowls varies according to the size of the teether.

These are typical scenarios to use a hay rake during grass and hay harvesting.

Sparse grasslands and open terrain

In areas with sparse vegetation and open terrain, many fields remain uncultivated. They may have low grass cover that requires frequent raking to keep the ground bare for the next planting. The open terrain makes it easy to rake more extensive areas without obstacles. Using a hay rake can increase the amount of grass harvested in these locations.

High humidity

In locations where it is usually hot and humid, grass grows faster than average. There is a need to rake hay more often to dry the grass thoroughly before storing it as hay. Storing damp grass as hay can lead to mold developing in the barn. Using a hay rake prevents this from occurring, even though the weather is not ideal for drying grass.

Mild weather

In temperate regions with pleasant climatic conditions and fertile soils, the annual hay yield can be higher than average. Because grass grows quickly, more frequent hay raking is required to keep up with the high volume of grass. At least two to three rounds of hay raking are possible on the same field each season. This increases efficiency and the amount of storage space needed for hay.

Dry weather and low humidity

In dry regions where humidity is always low, grass fails to grow at the expected rate. The amount of time and money spent on hay raking must be limited to avoid excessive expenses in these areas. Grass does not grow fast enough to justify frequent raking. Hay rakes are useful when needed rather than on a set schedule.

Frequent grass cutting

For farms where grass must be cut frequently, the grass clippings create a problem. If left on the surface, they will smother the lower grass and prevent it from growing. Hay rakes are needed to move the cut grass off the field to another location to avoid this situation.

When choosing the right hay rake for sale, wholesalers and business buyers should consider various aspects, such as the compatibility of different tractors, the ease of operation, and the potential for growth in the business.

Generally, a standard-sized tractor can work well with an average-sized hay rake. However, low-horsepower tractors may not have the necessary power to operate large rakes efficiently, and small tractors may only be compatible with a smaller rake. Therefore, it's essential to consider the capacity and size of the rakes that will work best with available tractors to avoid compatibility issues.

In addition to compatibility, it's critical to choose a rake that is easy to operate for staff. Complex rakes may require expert operators, which can lead to additional training expenses. Rakes that are easy to adjust and control will save time and money and allow an average employee to operate them safely and efficiently.

Storage is another essential factor to consider. A large hay rake will require more storage space than a small rake. Additionally, larger rakes may need to be stored outside, as they may not fit in any available storage areas. To protect stored equipment from the elements, tarpaulins and other covers must purchase, adding to the overall costs.

Growing demand for hay and potential income from customers looking for consistent and good-quality hay can be another good reason to invest in a more extensive and more efficient hay rake that can handle the increased production required to meet these demands. However, customers looking for consistent and high-quality hay will be more critical, and proper storage, fuel costs, and equipment wear and tear must consider when determining the potential for growth in the business.

Additionally, businesses should consider whether they have the staff needed to operate larger and more complex equipment. If not, it may be worth investing in simpler and smaller equipment that will be easy to operate and not require additional staff training.

Q1: How can users determine the proper horsepower requirement for a tractor to work with a hay rake?

A1: Users can consult the rake's manual to find the required horsepower. Also, they can consider the width of the rake, the type of grass, and the ground conditions. Typically, one horsepower per drawn acre is enough.

Q2: What are some signs that it is time to replace the teeth on a hay rake?

A2: Users should look for excessive wear, noticeable bending, cracking, or chipping. Also, if the teeth can no longer maintain proper ground engagement or flaring, it is time to replace them.

Q3: Can a hay rake handle wet grass or salvaging a flooded field's recovery?

A3: Yes, a rake can handle wet grass but may cause minor bruising, which is acceptable. It is better to salvage a flooded field than leave it un-hayed. Using the rake early, before the grass matures, may help improve later recovery.

Q4: Can a hay rake work without a hydraulic system?

A4: Yes, it is possible to work with a rake that does not have a hydraulic system. One can use a manual crank system to adjust the height and width of the rake.

Q5: Does a hay rake require any special tools for daily maintenance and minor adjustments?

A5: Yes, the rake may need tools like wrenches, pliers, and lubricating oil. The specific requirements will depend on the type and model of the rake.