Introduction to Grinding Cocoa Machinery

Grinding cocoa machinery is essential in the chocolate production and cocoa processing industries. These specialized machines facilitate the transformation of cocoa beans into a fine paste or powder, known as cocoa mass, which is a critical ingredient for creating delicious chocolate products. Understanding the nuances of grinding cocoa machinery helps businesses optimize production, enhance product quality, and meet consumer demands effectively.

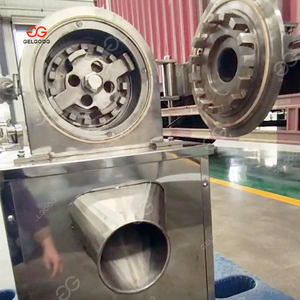

Types of Grinding Cocoa Machinery

There are various types of grinding cocoa machinery available, each suited for specific processing needs and production scales:

- Ball Mills: These machines use heavy balls to grind cocoa beans and achieve a fine consistency, ideal for large-scale production.

- Colloid Mills: Highly efficient for making smooth cocoa pastes and butter, colloid mills utilize shear forces to create a uniform texture.

- Grinders: Often used for smaller batches, these machines offer versatility and control over the grind size.

- Refiners: Essential for producing chocolate with the desired smoothness, refiners finely grind cocoa liquor in multiple passes.

Applications of Grinding Cocoa Machinery

Grinding cocoa machinery serves numerous applications within the food production sector. Here are some of the primary uses:

- Chocolate Manufacturing: Essential for producing chocolate liquor, cocoa butter, and cocoa powder as raw materials.

- Cocoa Butter Extraction: Used to separate cocoa butter from cocoa solids, a vital component for both confectionery and cosmetic industries.

- Snack Production: Enables the production of cocoa-based snacks, enhancing flavor and nutritional value.

- Cocoa Powder Creation: Housed in the final stage of the processing line to produce fine cocoa powder for baking, beverages, and more.

Features and Advantages of Grinding Cocoa Machinery

The grinding cocoa machinery comes equipped with various features that enhance processing efficiency and product quality:

- Precision Controls: Many machines offer adjustable settings for particle size, allowing for tailored textures based on specific product requirements.

- High Efficiency: Advanced grinding technology significantly reduces processing time and energy consumption.

- Durable Construction: Built to withstand rigorous use in industrial settings, leading to reduced maintenance costs and downtime.

- Automated Features: Modern machinery often includes automation capabilities, streamlining operations and minimizing labor costs.

- Food Safety Compliance: Designed with food-grade materials to meet safety regulations, ensuring the quality of the final product.

How to Choose Grinding Cocoa Machinery

Selecting the right grinding cocoa machinery is crucial for achieving optimal production outcomes. Consider the following aspects when making your choice:

- Production Volume: Assess your production needs to determine the capacity required; larger operations may benefit from high-capacity ball mills.

- Texture Requirements: Identify the desired consistency for your cocoa product—fine powders may require more advanced refining options.

- Budget: Evaluate your financial resources to find machines that offer the best balance between quality and cost.

- Maintenance and Support: Choose machinery from reputable suppliers who provide comprehensive support and spare parts availability.

- Technology Features: Consider modern innovations such as automation, control systems, and energy efficiency when selecting machinery.