(971 products available)

Grinder UL is an electric device used to grind food ingredients in the kitchen. It is certified by Underwriters Laboratories (UL) for safety standards. There are several types of UL grinders based on their working mechanisms and usage. Each type of grinder serves a different purpose and is suitable for various kitchen needs.

Hammer mill grinder

The hammer mill UL grinder is a widely used machine. It consists of many thick blades or hammers attached to a rotating shaft within a drum. The hammers repeatedly hit the material until it becomes small enough to pass through a screen at the bottom of the drum. This type of UL grinder is suitable for grinding spices, herbs, and grains. It is fast and efficient but may produce heat and noise.

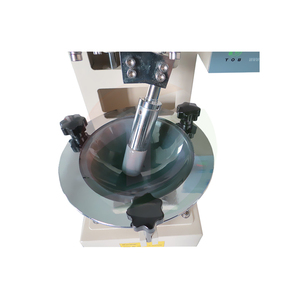

Bowl cutter grinder

A bowl cutter UL grinder consists of rotating blades and a stationary bowl. The blades chop and slice food into small pieces and are often used for meat, vegetables, and fish. This grinder gives a coarse texture and is suitable for making sausages, meatballs, or vegetable patties.

Beverage grinder

As the name suggests, the beverage grinder is used for grinding and crushing different types of beverages. These can include coffee beans, ice for drinks, and fruits for making shakes. These types of UL grinders are usually small in size and can be kept in the kitchen or even in the dining area.

Ball mill grinder

A ball mill UL grinder consists of a cylindrical shell containing balls that tumble and grind the material. It is used for powders, paints, and cement. The ball mill produces a uniform particle size and is suitable for materials that must not be heated during grinding.

Edge runner grinder

The edge runner UL grinder consists of two heavy rollers that move along the edge of a circular stone bed. This grinder is used for grinding large quantities of materials. It can grind wet and dry materials and is mainly used in the pharmaceutical industry.

Conical mill grinder

The conical mill UL grinder consists of a cone-shaped revolving screen. It can grind and classify materials simultaneously. It is widely used in the food, chemical, and pharmaceutical industries due to its low noise and dust generation.

The design of UL (Underwriters Laboratories) grinders is crucial to ensure safety, performance, and user satisfaction. They are made with safety standards and regulations set by UL, a nationally recognized testing laboratory. This section will explain the design aspects of UL grinders, focusing on safety, performance, ergonomics, aesthetics, and materials.

Safety Considerations:

The UL grinder is designed with many safety features to reduce the risk of accidents and injuries. They include overload protection, which stops the motor from running if it is overloaded, and anti-restart protection, which stops the grinder from accidentally starting up when plugging in. Also, they have cooling systems that prevent motors from overheating and casing designs that protect users from getting contact with moving parts.

Performance Aspects:

Designing UL grinders also consider performance aspects. These include powerful motors that can provide high torque for effective grinding and durable blades or grinding wheels for efficient material removal. Battery capacity and runtime are important for cordless UL grinders, ensuring they can work continuously without frequent recharges.

Ergonomics and Usability:

To ensure user comfort and reduce fatigue during extended use, UL grinder design incorporates ergonomics and usability. They have comfortable handles that provide a firm grip and control. Also, they are designed to be lightweight and balanced. Some UL grinders have features such as variable speed control, allowing users to adjust the tool's speed according to their needs, and indicators that show the battery status so users know how much power is left.

Aesthetic and Material Selection:

The appearance of UL grinders is influenced by the aesthetic and material selection. They can be finished with materials such as durable plastics or metal alloys, ensuring they are resistant to wear and tear, dust, and moisture. Also, UL grinders are designed to be visually pleasing, often incorporating sleek lines and harmonious color schemes that match modern tool aesthetics.

Metal Fabrication:

In metal fabrication shops, UL-rated die electric grinders are used to shape and finish metal parts. They are used to smooth weld seams, sharpen tools, and create complex metalwork designs.

Aerospace Industry:

The aerospace industry uses UL-rated pneumatic grinders for aircraft components. The grinders provide precise machining of engine parts, reduction of aircraft manufacturing materials, and polishing of flight surface hardware.

Automotive Industry:

UL pneumatic grinders are widely used in automotive assembly plants. They are used to grind cylinder heads, finish brake discs, and shape car body parts. The reliability and safety of the grinders are critical to maintaining a fast production line.

Construction Industry:

Construction sites use UL-rated wall electric grinders to finish walls. The wall grinder's ability to grind, sand, and polish wall surfaces improves the quality of finishing in buildings.

Masonry Work:

Masons use wall grinders to shape stones and bricks. The wall grinder can be used to create interlocking patterns in stonework or to shape bricks for specific wall designs.

Woodworking:

UL-rated die electric grinders are used to carve and shape wood. Electric grinders can create intricate designs, smooth out rough spots, or shape wood into desired forms in furniture making and art carving.

Repair and Maintenance:

UL-rated pneumatic grinders are used in repair and maintenance tasks across industries. They can restore worn-out tools, sharpen cutting equipment, and repair damaged machine parts. The versatility of the grinders makes them valuable for maintenance technicians who need to repair equipment in the field.

Medical Equipment Manufacturing:

The medical equipment manufacturing industry uses UL-rated pneumatic grinders to produce surgical instruments. The grinders provide precise machining to meet the stringent quality standards required for medical device manufacturing.

To choose the right UL grinder for specific needs, it is important to consider the following key factors:

Applications and Materials:

It is important to consider the specific applications and materials that will be processed using the UL grinder. What is the desired particle size reduction? What type of materials need to be ground? What is the hardness, moisture content, and abrasiveness of those materials? Considering these factors will help determine which UL grinder is appropriate for the applications and materials.

Grinding Mechanism and Features:

Different UL grinders use different grinding mechanisms. It is important to choose the one that best fits the grinding needs. For example, some UL grinders use blades for fast size reduction, while others use burrs for fine powder production. Looking at the special features, like the variable speed settings, safety features, and ease of use, can help identify the grinder with the necessary mechanisms and features for the specific requirements.

Capacity and Efficiency:

It is important to determine the required capacity and efficiency of the grinder. What is the desired output? What is the volume of material that needs to be processed within a given time? Choosing a UL grinder with sufficient capacity for the needs will ensure efficient operation. It is also important to consider the efficiency of the grinder to reduce energy consumption and increase productivity.

Size and Footprint:

Considering the available space for installing the UL grinder is important. How big is the grinder? What is the size and footprint? Choosing a UL grinder that fits within the space constraints without compromising performance is important.

Noise Level:

Some UL grinders can be noisy during operation, which may not be acceptable in certain environments. Considering the noise level produced by the grinder is important. If noise is a concern, choosing a UL grinder with noise-reduction features or low decibel ratings will ensure a quieter operation.

Ease of Operation and Maintenance:

Looking for user-friendly controls and easily accessible components for cleaning and maintenance is important. It ensures that the UL grinder is easy to operate and maintain.

Safety Standards and Certifications:

Ensuring that the UL grinder meets the necessary safety standards and certifications is important. Choosing grinders with safety features, such as emergency stop buttons, guards, and overload protection, will ensure safe operation.

Q1: What safety features should be considered when buying a UL grinder?

A1: Look for grinders with anti-re-start switches, wheel guards, and emergency stop buttons to ensure safe operation.

Q2: What is the expected lifespan of a UL grinder?

A2: With regular maintenance and proper usage, UL metal grinders can last many years, while heavy-duty models may have shorter lifespans.

Q3: Can worn grinding wheels be replaced on UL grinders?

A3: Yes, worn wheels can be replaced, but make sure the new ones match the grinder's specifications.

Q4: Are there any trends in the design of UL grinders?

A4: Users want grinders that are smaller and more powerful, with better ergonomics and connectivity features.

Q5: What are the benefits of investing in a premium UL grinder?

A5: Premium grinders offer better performance, durability, and safety features, which justify the higher cost for many users.