(4217 products available)

Granite cutting polishing tools are essential for processing granite into various products or surfaces. These tools include diamond saws, polishers, and various other machines. The following is a detailed description of each tool type:

The primary granite cutting tool is a cutting machine that uses diamond blades. These machines can cut granite into different shapes and sizes, such as straight lines, curves, and profiles. They are usually used in the initial processing of granite, including cutting granite blocks, slabs, and tiles. Common types of granite cutting machines include bridge saws, block cutters, and multi-saws. The bridge saw is the most commonly used granite cutting machine. It uses a fixed bridge to support the diamond blade and move it horizontally to make precise and straight cuts. Multi-saws can cut granite into multiple pieces simultaneously, making them more productive for cutting granite slabs into tiles or strips. The block cutter is usually used to cut granite blocks into smaller pieces, which are then processed by other cutting machines.

The granite polishing machine is used to polish granite surfaces to achieve gloss, smoothness, and beauty. The tool works by applying pressure to the surface of the granite with rotating abrasives, usually diamond abrasives. The granite polishing machine is available in various styles, from small hand-held tools to large automatic polishing lines. Automatic polishing lines are usually used in large-scale production and can polish multiple granite slabs simultaneously. Small hand-held or manual granite polishing machines are usually used for detailed polishing work, such as edge polishing or repairing damaged surfaces.

Granite drills are used to drill holes in granite for installation or other processing purposes. These drills are equipped with diamond drill bits that can cut through the hard surfaces of granite. The drill bits are usually used to create holes of different shapes and sizes, such as round holes, countersunk holes, or through-holes. Granite drills are available in hand-held, stand-alone, or automatic models to meet different processing needs and scales.

The granite milling machine is used to make various designs, shapes, and profiles on the granite surface. The machine uses rotary cutters and multi-edge cutters to cut and shape granite according to specific requirements. The granite milling machine is available in various styles, such as hand-held, automatic, or CNC (computer numerical control). CNC granite milling machines are the most advanced, which can achieve precise and complex milling operations by programming and controlling through the computer system.

Specification

Granite cutting and polishing tools are available in different specifications and features, depending on the specific task requirements. The key specifications are as follows:

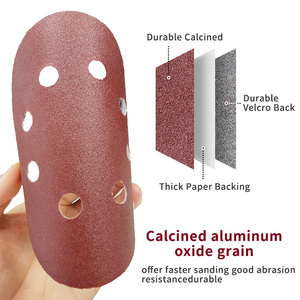

Granite cutting and polishing tools come in various types, such as diamond saw blade, diamond wire saw, diamond cup wheel, and polishing pads. Each tool is designed for a specific task, such as cutting, grinding, or polishing the granite surface.

Granite cutting and polishing tools are typically made of diamond, which is known for its hardness and durability. Diamond tools are capable of cutting and polishing granite with precision and efficiency.

Granite cutting and polishing tools have different designs to meet specific applications. For example, diamond saw blades may vary in tooth count and blade diameter. A higher tooth count can provide smoother cuts, while different blade diameters can be used for cutting different thicknesses of granite.

Some advanced granite cutting and polishing tools may have various features. For example, some diamond saw blades have laser-cut expansion slots to reduce vibration and noise during cutting. Some diamond cup wheels have water holes that can cool the working area and reduce dust. These features can improve efficiency and user experience.

Granite cutting and polishing tools may have different power types, such as electric, pneumatic, or hydraulic. The power types are suitable for different applications and operating environments.

Granite cutting and polishing tools may have accessories, such as cutting guides, water tanks, and tool boxes. Cutting guides can help users make straight and accurate cuts. Water tanks can provide water supply for cooling and lubrication. Tool boxes are convenient for storage and transportation of the tools.

Maintenance

Proper maintenance can extend the service life of granite cutting and polishing tools. Here are some tips for maintenance:

After use, clean the surface of the granite cutting and polishing tool, remove residual granite and abrasive particles, and then dry the surface with a clean cloth.

Granite cutting tools, such as diamond saw blades, need to be regularly sharpened. If the cutting edge becomes dull, it will affect the cutting quality and efficiency. Users can use a dressing stone or diamond dresser to sharpen the tool.

Granite cutting and polishing tools should be stored in a dry and ventilated place to avoid exposure to moisture and corrosive substances. It is also recommended to use protective covers or tool boxes to prevent damage and ensure the tools are securely stored.

For hand-held granite cutting and polishing tools, it is important to check the tightness of fasteners, such as screws and nuts. If the fasteners are loose, please tighten them promptly to ensure safe operation.

For high-power and large granite cutting and polishing machines, they require regular maintenance. This includes checking and changing the lubricating oil, inspecting the electrical system, and cleaning the air filter. Regular maintenance can ensure the performance and safety of the machines.

The granite cutting polishing tool kit has various applications in the construction and stone-working industries. Here are some usage scenarios:

Cutters and grinders help manufacturers create granite slabs, pavers, and tiles of precise dimensions. By using cutting machines, they adjust the granite pieces to various sizes and shapes. Polishing machines give the products a smooth surface and shiny finish. Manufacturers can meet the demand for custom designs as they cut, shape, and polish granite elements for countertops, walls, and floors.

Granite countertop production involves cutting, shaping, and polishing the granite pieces. Cutting machines are used to cut the granite slabs to the desired dimensions. Then, the edges are shaped with grinding tools. After the required shapes are achieved, the countertop is finely polished to give it a smooth and shiny finish. Countertop manufacturers use the granite cutting tool kit to produce high-quality granite countertops.

Architects use cutting and polishing tools to create intricate designs from granite. Cutting machines help them to make precise cuts in the granite material. After cutting, they use polishing machines to smoothen the surface of the granite and give it a glossy finish. Granite is used to make architectural elements like columns, balustrades, and decorative panels.

Granite is a popular material for making monuments and headstones. Monument makers rely on cutting and polishing tools to create beautiful monuments. Cutting machines are used to cut the granite blocks into the desired shape. Then, the surfaces are smoothed and polished to give the monument a beautiful finish. The polishing tool kit gives the granite monuments a smooth and shiny finish that enhances their beauty and longevity.

Repair technicians use cutting and polishing tools to fix damaged granite structures. Cutting machines are used to make the necessary cuts. They use grinding tools to remove the damaged parts of the granite and attain a smooth surface. Polishing machines are used to give the repaired surfaces a new finish. Repair technicians can make granite structures look new by using the cutting and polishing tools.

Whether for personal use or selling, it is important to consider certain things when buying granite cutting and polishing tools. For business buyers, it is important to be aware of the type of granite to work with. The hardness of the stone is a major determinant of the type of tool to use. For this reason, it is important to purchase a variety of tools to cater to different types of granite. Diamond blades are the most popular polishing tools for cutting granite. When buying diamond blades, it is important to consider the material of the granite and the type of machine to be used. If cutting sandstone, quartz, or other minerals with quartz-like particles, consider getting diamond blades made for cutting stone materials.

It is important to consider the thickness of the granite when buying cutting tools. Thinner blades are suitable for small and delicate projects, while thicker blades are ideal for heavy-duty projects. If cutting thicker granite, it may be necessary to consider tools with higher horsepower to achieve the desired results.

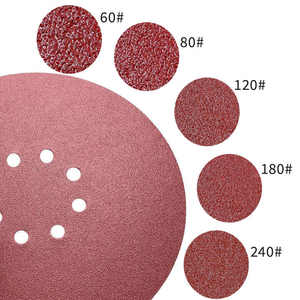

When buying granite polishing tools for resale, it is important to get tools that provide a smooth finish. Buyers are always looking for tools that will give their projects a professional finish. It is also important to get tools that are versatile to use with different granite types. Such tools can be used to cater to the different needs of customers. If buying cutting and polishing tools for personal use, it is important to get tools that are compatible with the machine in use. Also, consider the tools with different grits to achieve the desired finish. Some tools require coolants to function effectively. In such cases, it is important to buy the recommended coolant for safety and performance. Finally, buyers should consider the quality of the tools to ensure they are durable and can withstand regular use.

Q1: What are the benefits of wet cutting tools for granite?

A1: Wet cutting tools have many benefits, such as reducing dust and prolonging the lifespan of the cutting blades.

Q2: What is the difference between resin and metal polishing discs for granite?

A2: Metal polishing discs are generally more aggressive than resin polishing discs. However, resin discs provide a finer finish compared to metal discs.

Q3: What is the process of cutting and polishing granite?

A3: The process of cutting and polishing granite involves several steps, including marking and preparing the granite slab, cutting it to size using the appropriate cutting tool, and then polishing the surface to achieve the desired finish.

Q4: What are the safety precautions when using granite cutting and polishing tools?

A4: Safety is essential when using granite cutting and polishing tools. Always wear appropriate safety gear, such as goggles and ear protection. Familiarize oneself with the specific tool's manual and follow all instructions. Take extra precautions when handling the cutting tool. This may include wearing gloves and using two hands to control it.