Introduction to GK Motors

The GK motor is a pivotal component in various machinery, especially within the automotive, aerospace, and manufacturing industries. Designed for efficiency and reliability, GK motors deliver high performance while ensuring energy conservation. Their advanced engineering and technology make them a preferred choice for professionals and businesses aiming to optimize productivity and reduce operational costs.

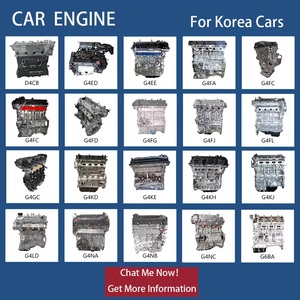

Types of GK Motors

GK motors are available in several types, catering to different functionalities and industry requirements. Here are some prevalent types:

- DC GK Motors: Known for their ease of speed control, DC motors are widely used in automotive applications.

- AC GK Motors: AC motors are ideal for applications requiring constant speed and high efficiency. They are commonly found in industrial machines.

- Stepper GK Motors: These motors provide precise control over position and are used in robotics and automation systems.

- Servo GK Motors: Offering feedback control systems, servo motors are tailored for high-performance applications requiring precise control of angular position.

Advantages and Features of GK Motors

Choosing a GK motor has several benefits, supported by its key features and functionalities:

- High Efficiency: GK motors are designed to minimize energy consumption while maximizing output, which is crucial in reducing operating costs.

- Durability: Constructed from high-quality materials, GK motors are resistant to wear and tear, ensuring longevity and reliability.

- Versatility: Available in various specifications and configurations, GK motors can be tailored to fit multiple applications across different industries.

- Low Maintenance: GK motors require minimal upkeep, allowing businesses to focus more on production rather than service interruptions.

- Enhanced Performance: With advanced technology, GK motors provide improved torque and speed performance, which is essential for fast-paced production lines.

Applications of GK Motors

GK motors find extensive applications across numerous sectors, each utilizing the motor's features to achieve efficiency and reliability:

- Automotive Industry: Used in electric vehicles and hybrid systems to optimize power management.

- Aerospace: Essential in aircraft systems for precise movement and operation of various components.

- Manufacturing: Integral in conveyor systems and machinery for assembly lines to enhance productivity.

- Robotics: Typically employed in robot joints and robotic arms where precision and control are paramount.

- Home Appliances: Utilized in devices like washing machines and air conditioners for efficient performance.