(4283 products available)

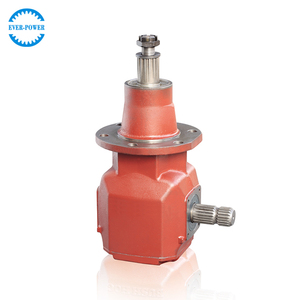

A gearbox agricultural reducer is a critical component used in farming machinery. Its key function is to adjust the speed and torque of the engine power. The changing of these factors enables different job requirements to be met throughout the farm operations. These reducers allow the machinery to perform tasks ranging from plowing to harvesting.

These reducers come in different types. Each of these types is suited to particular tasks and equipment. Here are the various gearbox agricultural reducers:

This type of agricultural gearboxes has teeth set at an angle on two intersecting gears shaped like cones. This angular inclination allows for smooth and quiet power transmission. It also eliminates much of the noise and vibration that other gear types produce. Its smoothness causes it to be preferred in equipment requiring high-speed reduction.

Common uses in agriculture include rotary cutters, mowers, and some tillage equipment. These tasks require a steady and smooth output of power. It is worth mentioning that the spiral bevel gear reducer is ideal for right-angle drive configurations.

The fifth wheel bevel gear reducers can be likened to the spiral bevels. Their main difference is that they use a more robust and durable design. This change is due to the heavy-duty applications they are often subjected to. They also feature a wheel-type component that helps in the absorption of shock loads. Thus, the fifth wheel bevel gear is suited for tough farming operations.

The common harsh agricultural conditions they often found themselves working in include tilling and heavy harvesting machinery. The fifth-wheel gear reducers are tough and efficient at distributing large amounts of power without wear and tear.

These reduce the gears that consist of parallel, flat ridges. The gears are mounted on shafts that are offset from one another. The teeth allow gradual engagement, resulting in silent operation compared to other gear types. This feature makes them ideal for operations that need steady power applications, such as irrigation systems and feed conveyors.

Helical gears are preferred less for high shock applications because of their susceptibility to shock loads. They primarily have a place in medium-duty agricultural equipment.

Planetary gear reducers are made up of three rotating elements. Two of these elements feature gears that mesh with a third central gear, which is the sun gear. They are known for their compact size and high torque capacity. They take up less space while efficiently powering large farming equipment.

Thanks to their design, they evenly distribute the gear load. This evenness allows them to be used in equipment that requires constant high torque. These are some of their common applications in the agriculture industry: electric drives, automatic transmissions, and precise feed mechanisms for drills and planters.

Gearbox agricultural reducers hold a variety of functions in the farming industry. They improve productivity and efficiently help the farm machinery's power be effectively utilized. Here are the various application business buyers can find in the agricultural shock-load reducers:

Gear reducers are used on tillers and plows to prepare the soil for planting. The tilling and plowing over the farming fields is a backbreaking and extremely tedious job. But with gear reducers being applied to the tilling and other soil preparation equipment, the process becomes a walk in the park.

These gears reduce the powerful engine's speed while increasing the torque for tillers and plows. The increased torque makes it possible for the machinery to penetrate hard soils and turn them over. It does this while lowering the rotating power, which could cause the surface to be tilled too finely and at a high speed.

These gears allow the establishment of crops in the best possible way by giving optimal control over soil preparation.

Proper irrigation is the key to healthy crops. Farmers have to ensure moisture is consistently available to their crops. Gear reducers play a huge role in electric and motor-driven pumps used for irrigation systems. They are crucial in providing the necessary reduction ratios that ensure these pumps have the proper torque to operate under the heavy loads of water pumping.

Without this ratio, the pumps would not be able to supply the right amounts of water. The farms' crops would then either go underwater or be given insufficient quantities. Furthermore, these reducers help prevent energy waste. This prevention also helps the pumps operate smoothly. Smooth operations make for better crop yields and lower energy costs for farmers.

Apart from the farming activities, gearboxes are also utilized in the transportation of farm products. Chain reducers can be found in livestock trailers. These trailers are used to transport cattle, sheep, and other animals from one place to another safely. Other basic enclosed gearboxes can also be used in agricultural trucks and other farm vehicles. These trucks are used to carry crops, hay, and other farming products.

They can even be used in external gear drive pumps. Farmers commonly use these pumps to pull water from a lake or river to fill up their trucks so that the transportation process does not run into any hiccups.

The right gear ratio is vital for the working parts of harvesters to operate efficiently. Harvesting equipment comes with complex operations that involve a lot of work. Harvesters need to cut, thresh, and winnow crops, which requires many intricate processes working in harmony.

Gear reducers help achieve this harmony by efficiently transferring the engine power to the various harvester components. Their right ratios correspondingly match each component's speed and torque requirements. This matching allows the harvester to maintain its precision even at high speeds and under heavy loads.

Gear Ratio

The agricultural gear reducers use various gear ratios to perform the various work they are called to do. The gear ratio is simply the ratio of the number of teeth on the driven gear to the number of teeth on the drive gear. A higher ratio means more reduction, which will give the machines more torque to work with.

Power Rating

These reducers are power-rated because they are designed to withstand specific horsepower or kilowatt levels. This power rating normally corresponds to the size and type of agricultural equipment in which the reducer is installed.

Output Torque

The output torque is directly related to the gear ratio. Higher gear ratios will have higher output torque. The torque produced by gear reducers affects the power they transmit to the machinery working on the farm.

SPlines and Shafts

The shafts and splines are designed to easily connect to both the input and output sides of the gear reducer. They ensure compatibility with the drive and driven equipment on the farm.

Installing an agricultural gearbox reducer is vital for the proper functioning of farm machinery. A reducer proportional to the engine power and certain machinery tasks should be chosen first. The farming conditions and the nature of the job the equipment will be doing should be taken into consideration.

The existing gearbox on the tractor or other farming equipment needs to be inspected after getting the right reducer. Any old oil or debris that may have accumulated over time should be cleaned off the equipment's gearbox. The output shaft on tractors and other farm equipment is connected to the gear input of the gearbox reducer.

Then the reducer is securely mounted to the tractor or other farming equipment using the appropriate hardware. After that, the proper oil type and amount are added to the gearbox to facilitate smooth reduction of turns. Finally, the gear ratio is set to the ideal working position. A trial run is performed to ensure everything is adequately working.

Routine maintenance is necessary for these gear reducers to ensure the reduction stays in good working condition. The oil levels should be regularly checked and the oil changed at least every six months or after a specified number of working hours. Old oil should be replaced with new oil because it will no longer have the right lubrication qualities. This situation will cause excessive wear and damage to the gears and bearings.

All the gear reducer parts should be inspected for possible indications of wear and tear whenever the oil is being changed. Cracks, rust, and other kinds of damage are examples of what to look for. Worn-out belts or other equipment parts should be fixed or replaced immediately so that the gearbox can function as it should. While doing this, no further pressure or load should be added to the worn-out parts.

Also, any misaligned or damaged pulleys should be fixed as they can cause further damage to the gear reducers. Farmers should always keep an eye out for unusual noises because they can be indicators of possible problems.

Selecting the right gearbox agricultural reducers for farming clients may seem like an overwhelming task. But having certain key factors in mind will make the process much easier.

The reduction ratio will clearly indicate the load and torque requirements of the gearbox agricultural reducers. A larger ratio means higher torque and lower speed simply because of the mechanical advantage factor. On the other hand, small ratios are fast-moving machines. They have low torque, such as the mower.

A gear that has an extra large ratio is not ideal because it will overload the machine and make the gearbox work harder than it should. Conversely, low ratios are inefficient because they are unable with sufficient torque to get the job done.

The input speed of the farming equipment should be considered when looking at operational speeds. This speed is the rpm of the power source, usually the engine or motor. It is important to ensure that the gearbox reduction ratios correspond to these speeds. If they don't, the farming machines will not operate as efficiently as they should. Some may not even get the job done at all.

A wide variety of housing designs and mounting types for the gearbox reducers are available. They are based on the various farming equipment they will be used on. Therefore, a mounted gearbox reducer grab farmers should has to house a certain machine's mount mean. It will ensure the reducer properly fits and works on the farmers' existing farming equipment.

The gearbox agricultural reducer type is influenced by the farming machinery the farmers use. For instance, planetary gearboxes are mainly used on drills and planters. Meanwhile, farming equipment like electric motors or irrigation pumps uses helical gearboxes.

Farming machinery that requires heavy loads, such as tillage equipment, uses gearbox agricultural reducers with high gear ratios.

Planetary gearboxes are favored for their compact size while still delivering high torque andieft ratios.

No, each farming machinery often has its own unique gearbox agricultural reducer. It is based on the nature of the job it will be doing.

Output torque influences how much power the reducer can transmit. It, therefore, affects the overall performance of the machinery.