(338 products available)

A galvanized webforge grating is a type of steel grating that is used as a flooring surface in industrial and commercial applications. It is made of galvanized steel, which means it has been coated with zinc to protect it from corrosion and rust. This webforge grating is designed to provide a strong, slip-resistant surface for foot traffic and heavy machinery. Below are some common types of galvanized webforge grating:

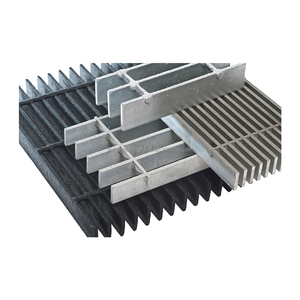

Bar Grating:

This type of galvanized webforge grating is constructed from linear steel bars. These bars are welded together to form a grid pattern. The grid pattern is then welded to crossbars. This creates a platform that can be walked on. The steel bars are spaced closely together. This makes bar grating a popular choice for walkways and catwalks. It is also used for applications that require high levels of airflow and light exposure.

Diamond Plate Grating:

Diamond plate grating is made from steel that has a raised diamond pattern. This pattern is found on the surface of the plate. The raised diamond pattern increases traction. It also makes this type of webforge grating slip resistant. This webforge grating is ideal for areas that experience high levels of foot traffic. It is also suitable for places where safety from slipping is a priority.

Heavy Duty Grating:

As the name suggests, heavy-duty grating is designed to support a lot of weight. It is made from thick steel bars. These bars are configured in a perpendicular pattern. This allows for maximum strength and durability. This type of galvanized grating is used in industrial applications. It is also used in places that experience heavy machinery traffic or large loads.

Fiberglass Reinforced Grating:

Fiberglass reinforced grating is different from other types of galvanized webforge grating. It is not made of steel. Instead, it uses a combination of fiberglass materials. These materials are combined with resins to create a lightweight but strong grating option. This type of grating is resistant to chemicals. It is also resistant to moisture and extreme weather conditions. It is ideal for coastal areas that experience high levels of saltwater exposure.

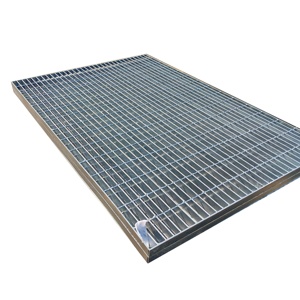

Rectangular Grating:

This webforge grating is characterized by a rectangular cross-bar pattern. The pattern provides a clean and modern look. It is suitable for architectural applications. It is also used in industrial settings that require visual appeal without compromising strength and drainage capabilities.

Galvanized webforge grating has a wide application in different industries, and its features make it popular among industries. Below are the functions of galvanized grating:

Walkway: This galvanized grating is used as walkways in different industries. Since it is galvanized, the steel grating is resistant to rust and can carry a load. It allows for easy and quick movement of people in industrial areas. Also, it is used in public areas like parks, stadiums, and other places.

Platforms: The galvanized webforge grating is used as platforms in different industries. It offers high strength, durability, and excellent corrosion resistance. The platform is ideal for carrying heavy loads and personnel.

Heavy-duty flooring: Heavy-duty flooring requires strong and durable material that can withstand the pressure of foot traffic. The galvanized webforge grating is used as heavy-duty flooring in industrial and commercial areas. It has a high load-bearing capacity and excellent slip resistance.

Drainage: Drainage systems in industrial and commercial areas need durable materials. The drainage system is exposed to water, and rust can damage it. Galvanized webforge grating is used in drainage systems because it offers high strength and corrosion resistance.

Air and light ventilation: Galvanized webforge grating is used in construction and industrial areas to allow air and light to circulate. It is suitable for use in areas that need ventilation and lighting.

Safety barriers: Safety is paramount in industrial and construction areas. Galvanized webforge grating creates safety barriers to protect workers and pedestrians from falling off edges. It can be used as handrails and guardrails.

The features of galvanized webforge grating include:

Corrosion resistance: The galvanized webforge grating is treated with zinc to offer corrosion resistance. This allows it to withstand different weather conditions and environments.

High strength-to-weight ratio: This webforge grating is lightweight but strong. It can carry heavy loads without bending or warping.

Slip resistance: The surface of the galvanized webforge grating is designed to be slip-resistant. It has a pattern or texture that offers traction even in wet or oily conditions.

High load-bearing capacity: This grating is ideal for heavy-duty applications. It can carry different loads ranging from light to heavy-duty loads.

Easy installation: Installing galvanized webforge grating is easy. It can be welded or bolted.

Galvanized grating serves different industries as a reliable flooring solution. It offers safe and secure walking surfaces. Here are the common usage scenarios:

Walkways and Trafficked Aisles

Galvanized grating is used in walkways and high-traffic aisles. The open-grid design allows drainage and prevents slip hazards. It has anti-slip properties that offer secure footing even when wet. The walkways are exposed to harsh weather elements, but the galvanized coating protects the grating from rust. The durable steel grating can withstand heavy foot traffic and industrial carts. It has a high weight-bearing capacity.

Machine Platforms and Workstations

Galvanized grating forms a stable platform for machines and equipment. The platforms allow air circulation and prevent heat buildup. The open-grid structure allows light to pass through and reduces wind pressure. Galvanized grating offers a strong surface for operators and machines. It can be fabricated into different sizes and load ratings. The platforms are usually cleaned regularly. The anti-slip surface and open-grid design make it easy to clean and maintain.

Industrial and Commercial Areas

Steel grating is widely used in factories, manufacturing plants, power stations, and refineries. It provides walkways, platforms, and flooring solutions. The galvanized coating protects it from rust and extends its lifespan. The grating is exposed to high-traffic areas and heavy machinery. It offers a durable and safe surface for walking and working.

Parking Garage

Parking garages experience vehicle movement and harsh weather elements. Galvanized grating forms a strong and durable surface for pedestrian walkways. It allows water runoff and prevents pooling. It also prevents vehicular and pedestrian slip.

Aquatic Facilities

Public pools, spas, and water parks use galvanized grating in high-traffic areas. The grating is exposed to water, air, and UV rays. The open-grid design allows water to flow and prevents slip.

When choosing the right grating for a particular application, consider the following factors:

Load and strength requirements

Consider the loads the galvanized webforge grating will support. Light loads are suitable for walkways and platforms in residential areas. Heavy-duty gratings are necessary for industrial applications, high-traffic areas, and applications with concentrated loads. These applications require strong and durable gratings to ensure safety.

Galvanization and corrosion resistance

Choose galvanized grating to ensure the longevity and durability of the product. The galvanization process provides a protective coating that prevents or minimizes oxidation and rusting. This is important in applications where the grating is exposed to moisture, chemicals, and harsh environments.

Open area and ventilation

The open area of the grating is important in applications where drainage, air circulation, and light transmission are required. High open areas are ideal for applications that require efficient drainage and ventilation. These applications include industrial platforms and walkways.

Slip resistance

Safety is the priority in areas with high foot traffic and where liquids are spilled often. Slip-resistant surfaces ensure the safety of persons walking on the grating. Slip-resistant gratings minimize the chances of slipping and falling, which is important for industrial, commercial, and even residential applications.

Ease of installation and maintenance

Factors such as the grating's weight, cutting and welding requirements, and installation methods should be considered. Lighter gratings are easier to handle and install. Products that require simple installation methods are also preferred. Low-maintenance gratings are cost-effective in the long run.

Aesthetics

This is important for applications in architectural and design projects. The appearance of the grating, its finish, and how it blends into the surrounding environment are all factors that should be considered.

Environmental considerations

Choosing a grating with minimal environmental impacts is important. Consider the life cycle of the grating, which includes the manufacturing process, raw materials used, and how the product is disposed of after its useful life. Select a grating that uses sustainable practices and materials during the manufacturing process.

Q: What is galvanized Webforge grating?

A: Galvanized Webforge grating is a type of flooring grid made from steel bars that form a web-like pattern. It is galvanized, which means it is coated with zinc to prevent rust and corrosion. This makes the grating durable and suitable for use in walkways, platforms, and industrial areas.

Q: What are the applications of galvanized Webforge grating?

A: Galvanized webforge grating is used in different industries, including construction, manufacturing, oil and gas, mining, and infrastructure. It is used in applications such as walkways, drainage covers, platforms, stair treads, and industrial flooring. It is also used in public areas like parks, stadiums, and commercial building entrances.

Q: How is galvanized Webforge grating installed?

A: The installation process depends on the type and layout of the grating. Generally, it involves preparing the support structure, placing the grating sections, and securing them using clips, bolts, or welding. It is recommended to consult the manufacturer's installation guidelines for detailed instructions.

Q: How is galvanized Webforge grating maintained?

A: Maintaining galvanized Webforge grating is simple. It involves regular cleaning to remove debris and dirt. This can be done using a high-pressure water hose or a broom. Inspect the grating periodically for any signs of damage or corrosion and address any issues promptly. If the grating is installed in a high-traffic area, consider more frequent cleaning and inspection.