Introduction to FRP Moulded Machines

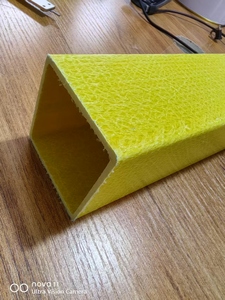

FRP moulded machines are advanced pieces of industrial equipment designed for the efficient production of fibre-reinforced polymer (FRP) components. These machines utilize innovative moulding techniques that combine excellent mechanical properties and corrosion resistance, making them ideal for a wide range of applications, particularly in industries such as automotive, aerospace, and construction. The growing demand for lightweight, durable materials in modern manufacturing processes has propelled the importance and relevance of FRP moulded machines.

Types of FRP Moulded Machines

FRP moulded machines come in various types, each tailored to meet specific production needs:

- Compression Moulding Machines: Optimized for bulk moulding, these machines apply heat and pressure to shape FRP materials. They are ideal for producing large, simple parts.

- Injection Moulding Machines: These machines inject resin into a mould to create intricate shapes, suitable for larger production runs with complex geometries.

- Vacuum Moulding Machines: Utilizing vacuum pressure, these machines ensure a thorough impregnation of fibres with resin, enhancing component strength.

- Hand Lay-Up Moulding Systems: A manual, labour-intensive process where workers lay down layers of resin and glass fibre in a mould, ideal for custom projects.

Applications of FRP Moulded Machines

The applications of FRP moulded machines are vast and versatile, supporting various industries with their engineered solutions:

- Aerospace: Used to manufacture lightweight structural components that improve fuel efficiency and performance.

- Automotive: Important in the production of body panels and interior components, reducing overall vehicle weight.

- Construction: Employed to create durable and weather-resistant elements such as pipes, panels, and architectural features.

- Marine: Essential for building hulls and other components that require corrosion resistance in saltwater environments.

- Electrical and Electronics: Used for producing insulating materials and housings for various electronic devices.

Advantages of Using FRP Moulded Machines

The advantages of FRP moulded machines make them a preferred choice in many manufacturing scenarios:

- Weight Reduction: FRP materials are considerably lighter than metals, contributing to lower shipping costs and increased energy efficiency.

- Corrosion Resistance: FRP components are highly resistant to chemical degradation, significantly extending the lifespan of products.

- Design Flexibility: The versatility of moulding methods allows for complex shapes and designs that can meet various aesthetic and functional requirements.

- Cost-Effectiveness: Although initial costs may be higher, the durability and reduced maintenance of FRP components lead to long-term savings.

- Reduced Labour Costs: Many FRP moulded machines automate elements of the production process, leading to less manual labour and quicker turnaround times.