(17866 products available)

Flex printing machines are the highly used machines for producing posters, hoardings, banners, labels, and many more. They are broadly categorized depending on the process that they use to print. Some commonly known types of flex printing machines include:

These printing machines use liquid inks which are applied to the material using anilox rollers. This type of machine is very much suited for flexo printing on materials like paper and corrugated boards. The ink used in this printing is Liquid in nature and dries off when the boards is run.

These machines utilize ultraviolet (UV) drying inks. The best thing about these inks is that they dry instantaneously when exposed to UV light. The highlight is that UV flexo printing machines are accommodated to produce printed material with better quality, glossy finish, and being moisture resistant.

These machines use inks based on water. These inks are less harmful compared to oil-based inks. Water-based flexo printing machines are an ideal choice for companies working with printing materials and are in need of a less toxic printing process.

This printing machine uses engraved metal or polymer plates to apply ink onto the printing surface. If any machine is very useful in niche label printing, it is the letterpress printing machine.

Flex printing machines are applicable to different kinds of industries and produce numerous types of end products.

Flex printing machines are extensively used in the packaging industry. They produce flexible packaging materials such as plastic bags, pouches, and wraps. The primary reason for this is their ability to print on a diverse range of substrates. It could be plastics, paper, or films. This adds to their versatility. Various packaging materials include food packaging, pharmaceutical packaging, and cosmetic packaging.

The textile industry does not want to be left behind in using flex printing machines. They produce printed fabrics for clothing, home textiles, and accessories. With the help of flex printing, it is possible to attain vibrant designs on fabrics. This makes it a much-preferred option for fashion designers and textile manufacturers. It is worth noting that eco solvent printers are optimal for outdoor use because they rigidly fight elements.

Flex printing machines mark labels and tags. These items are produced in bulk for retail products, packaging, and industrial goods. This printing provides clarity with which it produces detailed labels that bear vital information. Such information could be barcodes, instructions, and branding.

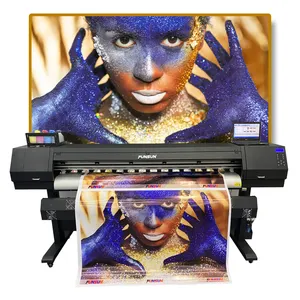

These machines are also used in producing high-quality signage and displays. Vinyl cutting machines are used to create banners, billboards, promotional displays, and point-of-sale materials. They provide the capacity to print large-size graphics with greater accuracy and resolution.

Flex printing machines are also used for printed stationery and promotional products. These could be customized business cards, brochures, promotional giveaways, and much more. This aids companies in presenting themselves with quality printed materials and promoting their business.

To avoid wasting time and money on unwanted products, businesses should focus on the following aspects when buying flex printing machines:

The main purpose a flex printing machine is going to serve should help in determining the materials it is going to print. If the machine is meant to be used for flexible substrates like plastic films, then having a machine with a flexible media feed system is key. On the other hand, if it's going to be used for rigid substrates like boards, a machine with a rigid media feed system is strictly needed.

Printing width is yet another critical factor. It could determine the performance of the production. What this essentially means is that wider printing machines have the capacity to handle larger jobs. They could also print more in a shorter time, thus making them suitable for companies that are into large-size printing. Narrow machines would do just fine for smaller jobs or for businesses that are constantly in need of diverse sizes of prints.

Flex printing machines are designed with different types of ink systems. For instance, water-based ink systems are more environmentally friendly. However, they may not provide as much adhesion on non-porous surfaces like oil-based inks. Solvent-based inks, on the other hand, are better for flexible substrates. It is worth considering the environmental impacts of the inks used in printing press machines.

Printing speed is a key consideration, especially for businesses that require high-volume printing. The speed of flex printing machines usually varies depending on printing width, substrate, and ink system. One key thing to look for is the drying system. This helps to enhance the efficiency of the overall printing process.

The technology of large format printers can significantly affect the quality, usability, and even operating costs. Modern machines are computerized and provide better control and precision in the printing process. They also have user-friendly interfaces for easy operation. Traditional machines, however, might be more reliable in terms of long-term use.

Mandatory maintenance requirements of flex printing machines are important factors to consider. In this case, how frequently the machine needs to be serviced defines its down times. The latter can be very costly for businesses that have high printing requirements. Now again, some flex printing machines come with low maintenance requirements and are also equipped with self-diagnosing.

Of course, cost is also a major factor. One has to consider not only the initial purchase price. Other costs could be operating costs, maintenance costs, and even ink and substrate costs. High-end flex printing machines are likely to come with advanced features. These, in the long run, might prove to be more cost-effective for high-volume printing businesses.

Flex printing machines are expensive and should be cared for through regular maintenance. In this case, some useful maintenance tips to ensure flex printing machines have optimal performance and durability are as follows:

Flex printing machines should be cleaned on a daily basis after use. This will help in avoiding ink sediments from accumulating and messing up the machine. The specific parts that require cleaning are the ink trays, anilox rollers, and plate cylinders. These are just examples of areas most affected by the ink. Cleaning can easily be done using prescribed cleaning solutions. This will ensure any kind of ink residue is removed.

Some of the weekly maintenance tasks include checking and tightening machine components such as belts, screws, and bolts. Other important parts that need attention are the head and nozzles. Weekly maintenance helps to enhance the operational efficiency of the machine. It also reduces the chances of mechanical breakdown.

Proper lubrication is one of the ways of maintaining flex printing machines. Lubrication helps to minimize friction between moving parts and, therefore, wear and tear. This wear and tear is associated with constant motion. Now, what lubricants to use should be sourced from the manufacturer's guide.

For machines that use ink-based systems, operators should always inspect the ink reservoirs. In this case, reservoirs that are low on ink can cause the machine to work harder to pull ink. This, in the long run, is going to affect the internal components of the machine. What this means is that always topping up ink levels is crucial for the machine's health.

This is in regards to machines with ink or solvent circulation systems. Such machines should have their filters changed regularly. Dirty filters can cause blockages, which in turn affects the quality of printing. More critically, it can lead to damage to internal components.

Flex printing machines are best operated under specific temperature and humidity levels. Too much heat or moisture can adversely affect the quality of prints and even the adhesion of inks. Companies that use eco solvent printers should be keen on this aspect as they are meant to enhance the environment.

Modern flex printing machines are computerized. They come with user interfaces operated through software. What this means is that maintenance of this software through regular updates is key. Up-to-date software is important as it offers optimal machine performance. Outdated software might create a loophole that hackers can use to penetrate systems. This will also lead to inferior printing quality.

The best way of ensuring any flex printing machine lasts long and gives its best performance is by following the manufacturer's maintenance guidelines. These guidelines are crafted with information from the original creator of the machine. They have a wealth of experience with their product.

A1. Machine manufacturers have employed themselves to ensure that their products are kind to the planet. In the lineup of flex printing machines, they have come up with a Water-Based Flexo Printing Machine. This is a breakthrough innovation in flex printing machines that reduces pollution by using water instead of solvents.

A2. Flex printing machines use different types of ink. These inks are the Oil-Based Inks and Water-Based Inks. Both these inks are used in flex printing machines and have their advantages and disadvantages. Oil-based inks are better used in jobs that need high durability. On the flip side, water-based inks are more environmentally friendly.

A3. Yes, flex printing machines can be used to print on shirts. With the renowned Flexo-Graphic Printing Machine, businesses can create vibrant and high-quality prints on fabrics. This makes the machine a popular choice among apparel manufacturers.

A4. Flex printing machines do not entail high maintenance. Basically, it needs daily cleanup and weekly inspections and lubrication. Further, thermoregulating components and software updates, coupled with adherence to the manufacturer's guidelines, can enhance the machine's lifespan.