(30139 products available)

A fine grinder is a powerful machine that breaks down tough, dry, and hard materials into fine powders and granules. It plays a vital role in many industries, depending on the essential final product required. It performs an extreme reduction in the overall size of substances through cutting, sealing, and crushing. Fine grinders contain heavy-duty blades and rollers that can efficiently grind food, rubber, plastic, spices, cement, etc., into fine material. The sort of fine grinder used typically varies according to the industry.

Some examples include:

The specifications of fine grinders vary depending on the kind and unit of the product.

Maintenance requirements will depend upon the type of fine grinder.

The application scenarios of fine grinders are diverse, covering a wide range of industrial and agricultural fields.

Milling wheat to make flour

Fine grinders play an essential role in food processing. For example, wheat is first crushed into small pieces by fine grinders before being further processed into flour by other grinders. Fine grinders offer precise crushing, meeting demands for high-quality end products.

Refining minerals and ores

In the mineral processing industry, fine grinders are used to refine minerals and ores, such as talc powder crushing. Fine grinders can enhance the liberation of valuable minerals, making subsequent separation processes more effective.

Processing spices and powder

Fine grinders are widely used in agricultural and food industries to process spices, coffee beans, cocoa, and other products into fine powders for flavoring and further processing.

Chemical production

Fine grinders are extensively utilized in chemical production, such as talc powder grinder machines, which can reduce chemicals into fine powder for use or make additives to enhance products' performance.

Milling raw materials for paints and coatings

In the paint and coating industry, fine grinders are employed to process pigments, fillers, and other raw materials, achieving uniform dispersion and fine milling to enhance the quality and durability of coatings and paints.

Sand and gravel aggregate processing

Gravel processing in the construction industry often requires fine grinders to produce fine aggregates such as sand used in concrete and mortar.

Material of construction

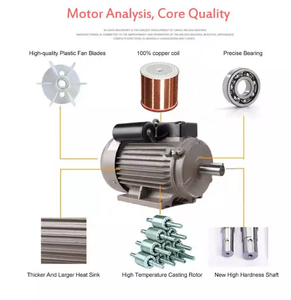

Food-grade stainless steel, mild steel, cast iron, and aluminum are acceptable materials for making a fine food grinder machine. However, only food-grade stainless steel is appropriate for making fine grinder machines for the pharmaceutical and chemical industries. Because, in those industries, there's a need for exceptionally sturdy machinery that will last a long time. In those cases, iron, aluminum, or even cast iron are unsuitable materials since they cannot withstand the considerable grinding pressure. Also, they will wear out quickly, which fine grinders in those industries cannot.

The energy source it uses

Electric Fine grinders are very popular, but there's a wide variety of electric fine grinders, ranging from those that run on 220 volts down to those that can run on as little as 12 volts. The higher voltage electric grinders are powerful, and their fine grinding speed is higher. However, that doesn't mean lower-voltage grinders won't fine grind food effectively. They will; it will just take a little longer. Battery-powered fine grinders are similar to low-voltage grinders in that they can run on 12 volts, making them suitable for use with a car battery.

Grind size options

A coffee grinder machine has variable settings to fine crush coffee beans, ranging from coarse to fine powder. Similar to this, other food matter have their own unique fine grinder requirements. Some machines let users choose the grinder size when grinding peanuts, rice, flour, and even coffee.

Brand reputation

A big brand electric fine food grinder will probably have more customer reviews than an unknown brand. There are advantages to working with well-known brands, such as easier replacement of parts. It's critical to ask questions about the unit's history before making a purchase when working with an unknown brand. This includes finding out anything about the suppliers' reputation. One must ensure that they possess the electrical and mechanical skills needed to resolve any problems that may arise over time.

Pricing

When determining the price of a fine powder grinder, both sides must consider the advantages and benefits the model offers. Offer the list of features and specifications so retailers can compare them with others. In addition to its features, the machine's age also affects its value. Because older machines won't be able to match the energy efficiency of modern ones. Fine grinders play a crucial role in increasing food product yield, lowering energy costs, and streamlining production lines.

Q1: What is the capacity of a fine grinder?

A1: Fine grinders are available in different capacities and are suitable for various applications. The capacity of the grinder depends on factors such as the motor power, final particle size, and material being ground. Fine grinders with small capacities, ideal for home use, can grind 1-4 kg of material per hour. For commercial use, fine grinders can grind anywhere from 50 kg per hour to several tonnes. Industrial fine grinders have the highest capacity and can grind up to 5000 kg of material per hour.

Q2: Which industries use fine grinders?

A2: Fine grinders are used in several industries for various applications. The grinder is an essential part of the food processing industry. It is used to mill spices and reduce the size of grains. Fine grinders are also used in the chemical industry to mill products such as pesticides, titanium dioxide, carbon, and more. In the mining industry, the grinder is used to break up ore in order to extract precious minerals and metals like gold and copper.

Q3: What are the safety features of fine grinders?

A3: Modern fine grinders have several safety features to ensure the safety of the operator and prevent damage. Overload sensors are fitted to grinding units to shut down the motor if it is experiencing excessive load in order to prevent damage. Furthermore, because fine grinders are big and heavy machines, they are usually mounted on a sturdy base and platform to prevent any accidental tip over.