(23603 products available)

Fiberboards are engineered wood panels made from wood fibers. These boards can be easily customized, and they are used in various applications. Some are as follows:

MDF is a versatile material used in cabinets, furniture, and interior trim. These fiberboards are made from wood fibers obtained by breaking down hardwood or softwood. The fibers are combined with a resin binder and then heated under pressure to create a dense, smooth board. MDF is preferred for woodworking since it can be easily painted, cut, and glued. It is also an economical alternative to solid wood due to its consistent quality and lack of knots or grain patterns.

MDF is available in various grades, such as standard, moisture-resistant, and fire retardant. It is also available with different surface finishes, from raw to veneer-faced or melamine-coated. MDF is used in the construction of cabinetry, furniture, shelving, and interior trim like baseboards and crown molding.

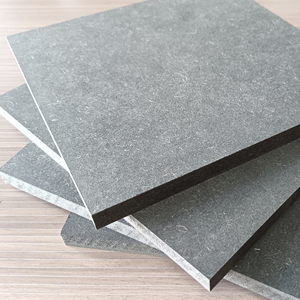

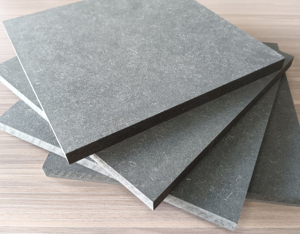

HDF is similar to MDF, but its fibers are pressed to a higher density. It is made from refined wood fibers and a resin binder that are subjected to high temperature and pressure. The resulting board is dense and uniform, with a smooth surface. HDF is typically used in applications where strength and durability are important. For example, it is used for underlayment under flooring materials like hardwood, laminate, and vinyl. Its smooth surface also allows for the direct application of finished flooring materials without the need for an additional substrate.

LDF is a type of fiberboard that is more malleable and flexible than its high-density counterpart. It is made from wood fibers that are combined with a wax emulsion and resin binder. The mixture is then pressed to form boards at a lower pressure than that used for MDF or HDF. LDF is used to make curved or molded parts in furniture, speaker enclosures, and products that require a more flexible material. It is available in different thicknesses and can be easily machined, shaped, and sanded.

OSB is another type of engineered wood board, but it is made by compressing strands of wood in specific orientations with a resin binder. These strands are usually mixed with wax and a resin binder, then pressed and heated to form a panel. OSB is used in structural and non-structural applications. It is a popular alternative to plywood due to its strength, dimensional stability, and cost-effectiveness. OSB can be used for sheathing, subfloors, and roofing. It is available in different grades and finishes, including smooth, textured, and tongue-and-groove edges.

Fiberboards are versatile and have many features suitable for different applications. Here are some of the features and functions of fiberboard:

Fiberboards can be cut into different shapes and sizes. The boards can be cut into custom shapes to fit into different applications. They are used in the packaging industry to manufacture custom inserts that hold products firmly during shipping.

Fiberboard can be finished with different materials to improve its appearance. Paint, laminate, and veneers are commonly used to coat fiberboard. The decorative finishes enhance the appearance of furniture, cabinets, and flooring.

Fiberboard absorbs sound waves, reducing noise in buildings. The boards are used to manufacture acoustic panels and ceiling tiles. Acoustic panels made of fiberboards are used in recording studios and theaters to enhance sound quality.

Fiberboards have good thermal and sound insulation. The boards are used to insulate walls, floors, and roofs in residential and commercial buildings. The insulation reduces heat loss in buildings during cold weather.

Fiberboards are engineered to resist moisture. Moisture-resistant fiberboards are used in areas with high humidity, such as kitchens and bathrooms. They are also used to manufacture baseboards and window trims.

Fiberboards are made from recycled wood fibers. The boards can be recycled at the end of their useful life, reducing environmental pollution. They are biodegradable and do not release toxins when they decompose.

Despite their lightweight, fiberboards are strong and durable. They are used as a backing material for countertops, flooring, and cabinets. The high strength provides structural support and prevents damage from impacts.

Fiberboards have uniform density and thickness. The boards are used to manufacture doors, shelves, and furniture. They provide a smooth surface that can be painted or laminated.

Fiberboards are easy to cut and shape using woodworking tools. The boards can be cut, drilled, and sanded to fit into different applications. They are used to manufacture speaker boxes, toys, and picture frames.

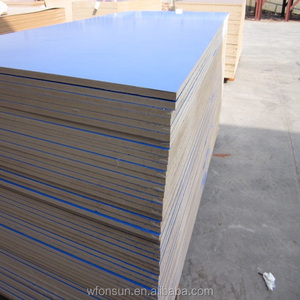

Fiberboards have an extensive range of applications in various industries. Here are some common usage scenarios of fiberboard:

Building houses and renovating them require fiberboards. They are used for making floors, walls, and ceilings. They are also used in roofing and underlayment, providing a strong and stable base for finished flooring.

One popular application of fiberboard is the production of furniture and cabinets. It is an excellent choice for furniture, shelving, and cabinetry in homes and commercial spaces. Fiberboard is usually painted, veneered, or laminated to create visually appealing pieces.

Fiberboard has great versatility, making it suitable for use in doors and windows. It can be used to manufacture door frames, window sills, and other structural components. It can also be used to make door panels.

Fiberboard is often used as an acoustic panel and insulation in soundproofing applications. It helps to reduce noise transmission between spaces by absorbing sound waves. It is also used as a thermal insulator in walls and ceilings, helping to conserve energy by providing heat retention.

Fiberboard is a popular choice for artists and craftsmen. It is commonly used as a base for painting, drawing, and mixed media art. It can also be cut, shaped, and decorated for various craft projects.

Fiberboard is used in various parts of automobiles and transportation products. It is used to make trim components, headliners, and under-hood applications. It is also used in the construction of trailers and truck bodies.

Due to its rigidity and robustness, fiberboard is used in industrial packaging. It is used to make pallets, crates, and boxes for shipping and storage. These packaging materials provide protection to products during handling and transportation.

Fiberboard is a common material for creating point-of-sale displays. It is used to make signs, stands, and product display units. Its versatility allows for customization to suit various retail and promotional needs.

When choosing the right fiberboard for any project, there are several factors to consider. The first is the intended use of the fiberboard. Different types of fiberboards are suitable for different applications. For example, hardboards are perfect for construction projects, while MDF boards are ideal for furniture making.

The next thing to check is the density of MDF wood. The density affects the strength and ease of shaping the board, so it is important to make sure it is correct. As a general rule, higher density fiberboards are stronger and more flexible.

Consider the environment in which the fiberboard will be used. If the area is exposed to moisture, it is better to choose a water-resistant fiberboard. This will prevent the fiberboard from rotting or losing its shape over time. Check the specifications of the board to see if it can withstand moisture.

Another essential factor to take into account is the finishing options. This is important because it can save a lot of time and money when working with the fiberboard. Check if the board comes with a pre-finished surface or if it needs to be painted or laminated. Pre-finished boards allow for quick installation and provide a professional look.

It is also important to check the size and thickness of the fiberboard. Make sure they are suitable for the project. Pay attention to the quality of the board, the brand, the warranty, and the reviews left by other customers. This will help to get a good idea of the fiberboard and make the right choice.

Choosing the right fiberboard may take some time, but it is worth it. Working with a quality board will make any project easier and ensure a great result.

Q1: What type of fiberboard is better?

A1: The answer to this question is not that simple. It depends on the project and the budget. For example, if someone is looking for high-quality boards, MDF boards are a good option. On the other hand, if someone is looking for something that is moisture resistant, then VLB or HDF board will be a good choice.

Q2: Are fiberboards environmentally friendly?

A2: Yes, fiberboards are environmentally friendly. This is because they are made from recycled wood fibers. Additionally, they are biodegradable, which means they do not release harmful chemicals into the atmosphere.

Q3: Do fiberboards have a high maintenance cost?

A3: No, fiberboards do not have a high maintenance cost. They are durable and long-lasting, which means they do not require a lot of maintenance.

Q4: Can someone paint fiberboards?

A4: Yes, fiberboards can be painted. However, it is important to prepare the surface before painting. The user can use sandpaper to smooth out the surface so that the paint can adhere easily.

Q5: How can someone clean fiberboard?

A5: To clean the fiberboard, use a damp cloth and mild detergent. Harsh chemicals can damage the fiberboard. Wipe off any excess water to prevent the fiberboard from absorbing moisture. Always make sure the fiberboard is dry.

Additionally, for specific applications, fiber cement board is an excellent option for areas requiring enhanced durability and moisture resistance, such as in bathrooms and kitchens.