(67 products available)

Fabric notchers are tools that are primarily used in the garment industry to cut notches in the fabric. The notches are useful when marking the fabric for the shape of the pattern pieces. There are many ways to create notches in the fabric, and fabric notchers cut either V-shaped or U-shaped notches in the fabric. They are often used in conjunction with the uncut fabric to identify the problem areas.

Usually, fabric notching machines are used when cutting curves or angular shapes. They are particularly useful when cutting notches in layered fabrics. They assist in streamlining the sewing process, helping to reduce the garment construction time, and can improve the accuracy of the final product.

Manual fabric notcher

A manual fabric notcher is typically a handheld device used to cut notches into the fabric. The tool helps the user to produce 'V' shaped cuts which are referred to as notches. The manual notchers usually have a cutting blade with a guard and a handle.

When using this notcher, the fabric is usually placed under the cutting blade in such a way that the area is to be notched is directly over the blade. The operator then holds the handle and presses it down so that the fabric is cut. Once done, the fabric can be removed to reveal the notch.

The manual fabric notcher is easy to use and allows the operator to cut several notches in various shapes and sizes. It can also be used to cut other materials besides fabric. The downside to it is that it is not used in sewing applications where precision is paramount. It can also be used in applications where there are not too many fabrics to be notched.

Electric fabric notcher

This type of fabric notcher is power-operated and is fast becoming a preferred choice in the garment industry. This is because it is more ideal for high-volume production due to its efficiency and speed. Like its manual counterpart, the electric notcher can be used to cut notches in other materials besides fabric. It can also cut in a variety of shapes and sizes, and what is more, the accuracy of the cutting is improved.

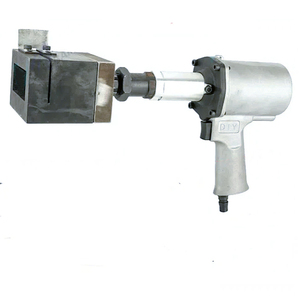

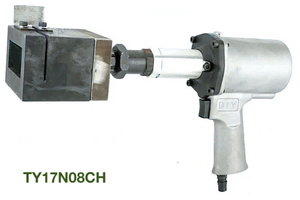

Electric notchers are made of electrically powered blades that cut through the fabric when the triggers are pulled. The downside of this notcher is that it requires some electrical hook up or battery power.

Automated fabric notcher

Perhaps the most advanced type of fabric notcher is the automated fabric notcher. This fabric notcher does not require any human intervention to operate. This type of notcher is integrated into computer-aided manufacturing (CAM) systems in the garment industry, such as cutting tables or automated lay cutters.

It is important to note that the automated notcher usually has a preset cutting pattern which is usually very intricate and complex. Once the fabric is laid out, the material will be cut in a specified pattern. Precision is a major benefit of this fabric notcher, as it creates identical notches every single time.

The downside to an automated fabric notcher is that it is a costly investment if the demand for notches in the fabric is not high.

Cutting Length:

Most fabric notchers are designed with varied cutting lengths to suit varied fabric cutting needs. The cutting length affects the notching size and number.

Cutting Depth:

Cutting/Notching depth refers to the maximum depth of the notch/cut that can be achieved. The cutting depth varies to ensure different aspects of notches are attained.

Cutting Thickness:

The cutting thickness refers to the maximum thickness of the material that can be notched. It varies depending on the fabric notcher machine type.

Cutting Blade:

The fabric notcher is equipped with a cutting blade made of diverse materials so that it can achieve various sorts of cuts. Some are electric-powered, while others are not.

Power Source:

A fabric notcher can be powered by a variety of sources. Electric fabric notchers, for instance, require power supply, while hydraulic ones use hydraulic power.

Inspect and clean:

Regularly examine the fabric notcher for any symptoms of wear or damage. Look at the blade for any bends, breaks, or dullness. If it needs cleaning, replace it.

Lubrication:

Every couple of weeks, oil the moving components of the fabric notcher to keep it running smoothly. This reduces friction, prevents frequent repairs, and ensures it runs efficiently.

Storage:

When not in use, keep the notcher in a cool and dry place to avoid any unexpected damages and prolong its lifespan.

The uses of fabric notcher are numerous. In pattern making, it is a vital tool in sewing to get accurate cuts on the fabric when creating patterns. Doing so helps create notches that show where seams should meet or indicate curves and angles within the design.

A fabric notcher is also essential in reducing errors during garment construction. By using fabric notchers as guides when cutting other materials like leather or paper, one can achieve similar accuracy and precision as with fabric cutting itself.

When sewing multiple layers of lightweight or slippery fabrics together, notching can be used to create a sewing guide. The notches will provide a reference for lining up the pieces and minimizing shifting during the stitching process.

In upholstery, it is crucial when trying to fit fabric around curves or irregular shapes. Notching allows for better draping and more straightforward manipulation of the material without compromising the final product's appearance.

Notchers come in different sizes depending on the type of fabric cutting machine they are meant to be used with. Electric notchers are standard because they produce cleaner cuts faster than manual ones, but all machines must have accurate notch placement to ensure notched patterns' notched lines correlate correctly.

Using a fabric notcher has several advantages, including accurate cutting, time-saving, and professional-looking results. Notching your fabrics can also help reduce fraying and make it easier to align seams when sewing curves or corners.

Choosing the right fabric notcher for retail or business use involves several critical factors and requirements that need to be taken into consideration.

Scale of Operation

The first thing to consider while buying a fabric notcher is to know if it is used for small-scale, larger-scale, or industrial-scale marking operations. This will tell customers what type or sizes of notcher to use and if it should be manual, semic-automated, or fully automated.

Nipping System

Various types of fabric notchers have been made available, each with its distinct fabric nipping system. It is very important to choose the fabric notcher based on the fabric nipping system used. Ensure the notcher fabric can effectively cut the types of fabrics used, providing clean and accurate notches. Buyers should choose based on how efficient the fabric nipping system is; this includes speed, precision, and ease of use.

The Accuracy of Cuts

A fabric notcher's primary purpose is to make precise notches for alignment, sewing, and cutting purposes. When choosing fabric notchers, asegur that it can offer clients highly accurate and precise cutting capabilities. The accuracy and precision level of fabric notcher cutting can affect the quality of the clients' garment production.

Size and Weight

Buyers should choose fabric notches that are of a suitable size and weight for their intended use. If they require a portable notcher, they should look for compact and lightweight models that allow them to move the notcher in and out of different locations, thereby permitting it to be used for various applications. If they require a stationary notcher, they should look for models that are of a suitable size and weight to be adequately serviced for their use. This will ensure that their production demands are met efficiently, and the notcher can cater to their garment production needs effectively.

Cost of Notchers

A fabric notcher's cost is the price the customer has to pay to buy the notcher, which is influenced by many things, including its model, brand, type, size, and other specific features. When making purchasing decisions, buyers should choose fabric notchers that fall within their budget constraints.

Q1: What are some limitations of fabric notchers?

A1: Fabric notcher machines may not be suitable for extremely thick fabrics, delicate materials that could get damaged, or complex shapes and curves that require high precision. Also, when using a fabric notcher, users must exercise caution to avoid dangerous and mishandling accidents.

Q2: Do fabric notchers have other uses apart from notching?

A2: Some fabric notchers may also trim, grade, or notch seams, eliminating the need for several machines.

Q3: Can a fabric notcher be used on leather?

A3: Leather can be used with a fabric notcher, but it depends on the material's thickness. Additionally, the leather must have a notching suitability characteristic. Fabric notchers are primarily intended for use on fabrics and similar materials.

Q4: Does a fabric notcher affect the garment's integrity?

A4: The garment's integrity can be affected if the notches are not carefully sewn over or if they are not appropriately adjusted. However, when the fabric notcher is used appropriately, the garment can be preserved.

Q5: How many notches can a fabric notcher make in an hour?

A5: The number of notches a fabric notcher can make in one hour depends on the buyer's notcher model, fabric type, notching complexity, and operator skill level. Electricity-powered notchers can make thousands of notches per hour, unlike manually operated machines.