(145 products available)

There are several types of ER bobbins, each with unique features and applications in the textile industry.

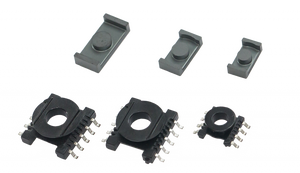

Standard ER Bobbin:

The standard ER bobbin is the most common type of ER bobbin. It is usually made from plastic or metal. Standard bobbins fit various sewing machines, from domestic to industrial use. Bobbin holders and cases are designed to hold standard bobbins securely as the sewing machine works.

Industrial ER Bobbin:

Industrial ER bobbins are usually more prominent than standard bobbins. Use them for industrial and heavy-duty sewing machines. They hold more thread to allow longer uninterrupted sewing. Like standard ER bobbins, industrial bobbins can be made from either plastic or metal.

Plastic ER Bobbin:

As the name implies, plastic ER bobbins are small plastic disks. They are lightweight and easy to handle. Plastic bobbins suit various applications, such as sewing, embroidery, quilting, and more. One notable downside of plastic ER bobbins is that they crack or break faster than other types.

Metal ER Bobbin:

A metal ER bobbin is made of durable metal alloy. This gives it a heavier weight and more thread capacity than plastic bobbins. Metal bobbins last for many years. They are ideal for high-speed sewing machines that have great precision. However, metal bobbins can get slightly damaged over time due to thread wear.

Material:

Er bobbins are made of plastic, wood, or metal. Plastic bobbins suit basic sewing needs. Wood bobbins can give a vintage sewing machine character. Metal bobbins are ideal for heavy-duty sewing machines that use more robust threads and need lasting products.

Size:

Bobbins have different sizes. Small, medium, and large bobbins fit various types of sewing machines. The smaller the bobbin, the less thread it will hold.

Design:

Functional bobbins wind thread tight. Decorative bobbins may have an open design to show colored threads. Designer bobbins are also created to match popular themes.

Clean:

Wipe the er bobbin with a clean cloth to remove the dust build-up. Use a ziplock bag to keep bobbins dust-free. Avoid using soap or cleaning solutions that leave chemical residue.

Keep thread even:

Put thread tension on the bobbin winder when winding new thread. Maintain the same tightness of thread to ensure even wear of the bobbin.

Store:

Store bobbins vertically or in a bobbin holder. Bobbins can get tangled when stored horizontally. Bobbin holders have separate slots for each bobbin.

ER steel bobbins have various usage scenarios in the textile industry and different machine work environments. Here are some of them:

Textile industry:

They are mainly used to hold threads during sewing operations. This applies to both garment industries and the high-fashioned accessory industries where stitching is an integral part of the product. ER bobbins are also used in weaving equipment to hold the threads that will be used to create the fabric.

Sewing machines:

The bobbins are typically housed in a metal case or a plastic bobbin holder. Specific sewing machine models call for particular types and sizes of bobbins. ER bobbins are available in different sizes and materials to accommodate various sewing machines, including industrial, standard, and overlock machines.

Embroidery:

In embroidery, whether on challenging-to-embroider surfaces that require a specific bobbin thread weight, color matching, support woven under the embroidery, or as a backing to help prevent the fabric from tearing, bobbins of finer threads are commonly used. They may also be utilized to hold lighter threads in other embroidery projects. Small, intricately stitched, often brightly colored designs can be more accessible and quicker to produce with the help of bobbin embroidery, which entails sewing designs directly onto the fabric's reverse side.

Quilting:

The quilting process may use bobbins to assist in stitching patterns and completing the quilting processes, especially in free-motion or computerized quilting. Bobin sewing results in stronger, more durable quilts where seams are adequately reinforced, and blocks are securely joined. Bobin sewing helps uniformly distribute the quilt layers and ensures that the back fabric is accurately marked with the intended quilting design.

Leather and heavy-duty materials:

Bigger and heavier metal bobbins are often employed to handle thicker threads and heavier materials in leatherwork and heavy-duty applications, such as canvas and denim. These materials require strong, robust seams and threads that can withstand wear and tear, which heavy-duty metal bobbins are well-suited to provide.

Home sewing:

Home sewing projects often require the use of bobbins, and if they are used up, home sewers will be enticed to buy more.

Whether sewing machine bobbins for sale are going to be used for industrial or domestic purposes, there are a few things to consider when choosing them for resale.

Compatibility with sewing machines:

ER bobbins are designed to suit specific types of sewing machines. When choosing them for resale, it's essential to think about the kind of machines customers may use their sewing bobbins with. Select a range of bobbins that will fit various ER sewing machines.

Quality material:

Sewing machine bobbins are typically made from plastic or metal. ER plastic bobbins for sewing machines are lightweight but may break easily. Metal bobbins are more durable and provide better tension, but they are heavier than plastic ones. Shop owners can choose a variety of materials to sell so their customers can have options to choose from.

Size variety:

As mentioned above, ER sewing machine bobbin sizes differ. When shopping for bobbins to sell, buyers should get a variety of bobbin sizes for different sewing purposes. This ensures customers won't struggle to find bobbins for their specific sewing needs.

Packaging:

Packaging is important when selling sewing machine bobbins. Packaging makes it easy for customers to store their bobbins. It's also easier for customers to identify the type and size of the bobbins. Packaging should be selected carefully when buying bobbins in bulk.

Q1: What are ER bobbins made of?

A1: ER bobbins can be made from several materials, including plastic, steel, aluminum, or ceramic. Each material has advantages that make it ideal for specific types of sewing machines.

Q2: Can ER bobbins fit other bobbin cases?

A2: No, bobbins are manufactured to fit specific bobbin cases. Using improperly fitting bobbins can create tension problems or jamming in the sewing machine.

Q3: Is there a difference between E and D ER bobbings?

A3: Yes, there is a difference. While both are cylindrical, the E style bobbin is longer than the D style bobbin. The E bobbin will fit in certain sewing machine models but not others that require the D model.

Q4: Can unused ER bobbins go bad after a while?

A4: If they are stored in unsuitable conditions, unused ER bobbins can go bad. This will happen if they are exposed to extreme temperatures or humidity or direct sunlight for extended periods. It's best to store them in a dry, cool, and dark place.