Introduction to Equip FEP

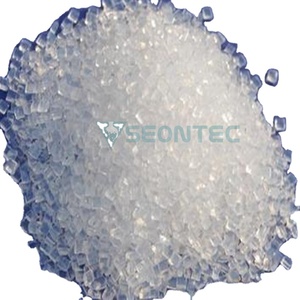

Equip FEP (Fluorinated Ethylene Propylene) represents a unique class of materials that offer exceptional properties for a wide range of industrial applications. Known for its stability and resilience, Equip FEP is a thermoplastic that exhibits remarkable chemical resistance, outstanding thermal properties, and excellent electrical insulation. Whether you're operating in the chemical, food, or medical sectors, Equip FEP is designed to meet the robust demands of modern industry while ensuring safety and efficiency.

Types of Equip FEP

Equip FEP comes in various forms tailored to diverse industrial needs. Understanding these types is crucial for selecting the right material for specific applications:

- Films and Sheets: Thin layers of Equip FEP that are versatile and suitable for coating or lining applications.

- Tubing: Flexible and durable tubing for transporting corrosive materials, maintaining integrity under high temperatures.

- Rod and Bar: Solid shapes ideal for machining into customized components, offering strength and longevity.

- Flanges and Gaskets: Specialized components providing reliable seals in piping systems, preventing leaks in demanding environments.

Applications of Equip FEP

The versatility of Equip FEP makes it suitable for a multitude of applications across different industries, enhancing productivity and safety.

- Chemical Processing: Its chemical resistance allows Equip FEP to be used for reactor linings and hoses in chemical plants.

- Pharmaceutical Manufacturing: Equip FEP is ideal for bio-process applications where cleanliness and high purity standards are mandatory.

- Food Industry: Non-toxic and FDA-approved grades of Equip FEP make it suitable for food processing, ensuring food safety without compromising quality.

- Electrical Insulation: With remarkable dielectric properties, Equip FEP is utilized in various electrical insulating applications, battery technologies, and cable coatings.

Advantages of Equip FEP

Choosing Equip FEP not only enhances the operational efficiency of various processes but also ensures longevity and performance excellence. Some notable advantages include:

- High Thermal Stability: Equip FEP can withstand extreme temperatures without degrading, making it perfect for high-heat environments.

- Exceptional Chemical Resistance: This material withstands a wide range of corrosive chemicals, reducing the risk of premature failure and costly replacements.

- Low Friction Coefficient: Equip FEP surfaces minimize wear and tear while facilitating smooth movement, crucial in mechanical applications.

- Extreme Flexibility: Despite its strength, Equip FEP maintains flexibility, making it easy to handle in various manufacturing processes.

- Easy to Clean: Non-stick properties allow for straightforward cleaning, essential in industries that prioritize hygiene and cleanliness.