(343 products available)

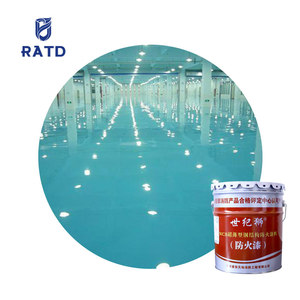

Liquid fireproof paint is available in several types of epoxy flooring, each constructed for different environments and demands. These paints offer insulation against fire and play a crucial role in maintaining the structural integrity of buildings.

This paint swells upon exposure to heat, resulting in a thick insulating layer that traps heat. Therefore, it is used on steel structures to keep the temperature below critical levels. Moreover, it is lightweight, which makes it ideal for construction applications where minimal weight is necessary.

This type of paint is based on cement and provides a hard, sprayable coating that is well-respected for its excellent adhesion to various surfaces. Also, it offers a high level of fire resistance and is ideal for industrial settings. Furthermore, it is used in spaces that may require exposure to chemical agents.

This fireproof paint closely bonds with the substrate to create a solid, sturdy shield against flames. Monolithic coatings are often applied to concrete structures and provide a high level of protection. More importantly, they combine fireproofing with durability, which makes them ideal for heavy-traffic areas.

This paint includes fiberglass strands to boost its strength and insulation properties. They are usually applied in high-risk environments that require an additional level of fire protection. This coating forms a robust layer that can withstand intense heat and mechanical impact.

Available as ready-to-use mixtures, these coatings can be effortlessly and uniformly sprayed onto diverse surfaces. They are suitable for large areas and complex substrates, where manual application might be less efficient. Also, they can be constructed from either intumescent or cementitious materials.

The high demand for liquid fireproof paint comes from the need for safety, durability, and aesthetic value in numerous settings. This versatile product not only aids in fire protection but is also designed for use in commercial, residential, and industrial applications. Below are some of the ways this product helps meet specific needs.

Concrete floor paints used in industrial setups face a barrage of threats daily, including heavy machinery, chemicals, and extreme temperatures. Fireproof paint not only safeguards structural elements by adding a protective layer but also boosts the lifespan of equipment and minimizes fire-related downtime. Additionally, its durability handles high-traffic volumes and adverse conditions without a hitch.

Safety is a top priority in restaurants, hotels, and retail stores. Fireproof paint enhances aesthetics while providing the necessary safety standards. It reduces insurance costs by lowering fire risk, therefore boosting the establishment's overall value. Moreover, many products are available in eco-friendly formulations with low volatile organic compounds (VOCs), making them safer for use in occupied spaces.

Today, homeowners value fireproof paint for its dual protective and aesthetic qualities. It protects vital structural elements like beams and columns while preserving the paint's sleek, polished look. This maintains the home's appeal and resale value. Additionally, many fireproof paints are available in various colors and finishes, enhancing the overall design.

Safety and compliance are critical in this high-risk industry. Fireproof paint protects structures from extreme temperatures while ensuring they meet regulatory standards. Additionally, the paint's resistance to harsh chemicals means that equipment and structures remain sheltered even under the most adverse conditions.

School districts frequently apply fireproof paint to safeguard students and staff. It protects critical infrastructure and reduces liability by lowering the fire risk. Moreover, this paint is usually long-lasting and easy to maintain, which reduces the overall cost over time.

Understanding the specifications and maintenance requirements for liquid fireproof paint guarantees optimal performance and longevity. This paint is a crucial component in fire resistance, ensuring structural integrity and safety across multiple settings. Thus, thorough knowledge of this product will help users get the most out of this investment.

Coating Thickness

The paint's thickness is vital for meeting fire-resistance standards. Typically, these thicknesses range from 15 to 50 mils, depending on the intended level of protection. Ensure that the paint is applied evenly to meet these requirements.

Fire Resistance Rating (FRR)

This rating denotes the duration the paint can endure fire. Ratings may commonly be from 30 minutes to several hours. Select paint with an FRR appropriate for the building's or area's needs.

Temperature Range

Paints are constructed to resist specific temperatures. Typically, these paints protect against up to 1,500°F. Choose a product that serves the unique demands of the environment where it will be applied.

Composition

Liquid fireproof paints contain intumescent materials, cementitious compounds, or a blend of both. Each composition type offers unique benefits. Therefore, understanding them will ensure the right choice is made for distinct applications.

Application Method

Many fireproof paints are constructed for simple application by brushing, rolling, or spraying. However, others may require professional application. Thus, refer to the manufacturer for specific guidelines regarding application.

Regular Inspections

Conduct inspections to identify any signs of wear, damage, or loss of efficacy. Look for chipping, peeling, or discoloration, as these could indicate reduced fire resistance.

Cleaning

The build-up of dirt or debris may compromise the paint's protective qualities. Use a soft brush and mild detergent to clean the surface regularly, as harsh chemicals can damage the paint.

Touch-Ups

As required, perform touch-ups to fix any damage or wear that may have occurred. Ensure that any repair paint used complies with the original paint's specifications to maintain uniformity in protection.

Reapplication

Over time, the efficacy of fireproof paint will eventually decrease. Follow the manufacturer's recommendations regarding reapplication to ensure ongoing compliance with fire safety regulations.

The right liquid fireproof coating is selected according to environmental demands, budgetary considerations, and performance expectations. With the right choices, this paint provides invaluable protection over the years.

It's important to consider the environment in which the paint will be applied. For instance, high-risk areas in the oil and gas sector require paints capable of withstanding extreme temperatures and chemicals. Meanwhile, paints for commercial buildings should have low VOCs so that they do not affect indoor air quality. Understanding environmental factors ensures that the paint chosen meets safety and ecological standards.

Although epoxies may have an effortlessly appealing upfront price, long-term costs are definitely worth considering. Quality paint will often require fewer repairs or replacements. Additionally, it may offer lower insurance premiums due to its ability to improve fire resistance. Weighing these costs helps in making decisions based on total cost of ownership, not just initial investment.

Consider the intensity of the activity or traffic that the painted surface is likely to encounter. Coatings with additional durability and high gloss levels will be better suited for industrial and commercial areas. Conversely, those intended for use in residential settings may require coatings with more aesthetically appealing finishes.

The paint must adhere to local fire regulations and codes. Many fireproof paints come with pre-approved certifications for specific industries. Thus, selecting one of these paints not only simplifies the compliance process, but it also provides a peace of mind.

Many reputable manufacturers back their products with strong warranties. These warranties usually cover paint failure due to poor workmanship or the element the paint was designed to withstand. Additionally, manufacturers who provide technical support are available to answer questions about application or maintenance that may arise down the road. Selecting a paint from a company with a solid warranty and support may add extra confidence in the product's performance and longevity.

A1: The number of coats depends on the paint's specifications and the fire resistance rating (FRR) required. Usually, two to three coats offer the best protection, with each coat building upon the last for enhanced thickness and efficacy. Manufacturers must be consulted for specific recommendations on the number of coats and how to apply them.

A2: Some fireproof paints are constructed to handle outdoor conditions. These paints include weathering agents that guard against UV radiation, moisture, and temperature variations. If the paint is fireproof, it can easily be used outdoors.

A3: Fireproof paint may alter the look of the epoxy flooring if proper precautions are not taken. Many paints are available in various colors, allowing buyers to select one that complements the floor. Additionally, the paint's texture may cause the floor to appear different. However, using a paint application technique that keeps the texture low will assist in keeping the floor as close to its original appearance as possible.

A4: Most fireproof paints are straightforward to apply. It can be brushed, rolled, or sprayed onto surfaces. Nonetheless, some types, like cementitious coatings, require professional installation due to their complexity. Always follow the manufacturer's guidelines for proper application to achieve the best results.

A5: The longevity of fireproof paint is determined by factors such as the environment, level of activity, and paint type. Generally, fireproof paint should be reapplied every 5 to 15 years. However, frequent inspections and maintenance will ensure the paint continues to perform optimally long after the initial application.