(4586 products available)

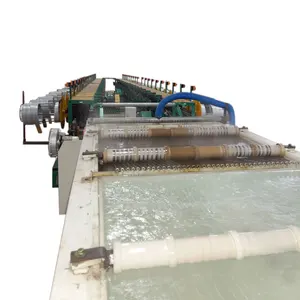

Automatic Electroplating Machines :

An automatic electroplating machine controls the electroplating process using a computer or other programmable devices. With this machine, operators can precisely control various plating parameters, including temperature, voltage, current, pressure, time, plating speed, thickness, and more. Moreover, the machine can automatically adjust these variables according to the preset program to ensure a uniform and stable plating quality on all workpieces. Automatic electroplating machines may also include additional features, such as fault alarms, data storage, remote monitoring, and others, to enhance production efficiency and product quality further.

Brush Electroplating Machine :

A brush electroplating machine is an equipment that uses an electrochemical deposition process to coat metal on a surface using a brush. Electroplating with a brush is a process in which a solution containing metal ions is applied to the surface to be coated by a conductive brush. The process involves applying a voltage that causes the metal ions in the solution to be attracted to and deposited onto the surface, forming a coating. This method allows for selective plating of localized areas, providing the advantage of precise control over the plating process.

v

A vibratory plating machine is a specialized equipment that uses a vibrating motion to promote the uniform deposition of metal on the surface of workpieces. The plating solution is typically held in a bowl or container, which is then vibrated to mix the solution and evenly distribute it over the surface of the item to be plated. This method enables uniform metal deposition, making it suitable for plating small parts or intricate shapes. Vibratory plating machines are commonly used in the electronics, automotive, and jewelry industries, among others.

Hard Chrome Plating Machine:

A hard chrome plating machine is used to deposit chromium metal onto various substrates through an electroplating process, forming a hard and thick chromium layer. This coating machine is widely used in manufacturing industries to enhance the surface hardness and wear resistance of tools, molds, mechanical components, and more, thus prolonging their service life and maintaining their precision.

Nickel Electroplating Machine:

A nickel electroplating machine is a device that electroplates nickel on the surface of objects. The primary purpose of nickel electroplating is to provide a decorative finish or improve the corrosion resistance, wear resistance, and friction property of the substrate. This machine usually consists of a plating tank, power supply, circulation, and filtration system, as well as temperature control and other functions. The plating solution of nickel electroplating is usually nickel sulfate or nickel chloride solution, and the current density and temperature during the electroplating process will affect the coating's structure, properties, and thickness.

Electroplating Machine Size:

Typically, a medium-sized electroplating machine for zinc galvanizing could measure about 3 meters in length, 2 meters in width, and 2.5 meters in height. Larger industrial machines may have containers up to 12 meters in length. Custom sizes are available for specific larger or smaller requirements.

Production Capacity:

An electroplating machine's productivity depends on its size, the pieces being plated, and the plating thickness. A machine with a tank capacity of 1,000 liters might process 200 metal parts per hour if each takes five minutes to plate. The production speed could be increased if each part requires only 2 minutes of plating time.

Power Usage:

This is normally stated in kilowatt-hours (kWh). For example, a small electroplating machine's power consumption could be around 5.5 kW, resulting in monthly consumption of 1,000 kWh. This equals approximately 300,000 kWh annually. A larger industrial machine may consume 20 kW, which is around 6 million kWh annually.

Pump Flow Rate:

Electroplating machines use pumps to circulate the plating solution; the typical flow rate is around 250 liters per minute. The flow may be as high as 1,200 liters per minute, depending on the size of the machine and the capacity of the pump used.

Maintenance of electroplating equipment machines involves regular inspection, repair, and servicing of parts like pumps, tanks, and piping. It ensures safety, product quality, and minimal environmental impact. A maintenance schedule is needed. It should include daily, weekly, monthly, quarterly, half-yearly, and yearly maintenance tasks along with the equipment parts that must be serviced, repaired, or replaced. Create a list of all required tools, equipment, spare parts, and safety gear for every maintenance activity.

Avoid any electrical maintenance without consulting with certified electrical professionals. They will determine whether any parts require repair or replacement, as electroplating equipment has a large amount of electrical wiring and equipment. If any pumps or motors are directly connected to the equipment, they will also inspect those parts.

Adhere to safety standards. It may involve the establishment of lockout/tag-out procedures to ensure employees are safe whenever electroplating machine maintenance occurs. Employees will be protected from unintended equipment startup during maintenance activities. Ensure all chemicals are safely stored so that employees have no risk of access to them. Hazardous waste should be stored according to industry standards to prevent any contaminants from improperly entering the waste stream or the environment.

The application of electroplating machines is vast, especially for industries using machines such as the electroplating machine for metals.

Manufacturing Heavy-Machinery Parts:

In industries where heavy machinery is used, an electroplating machine galvanizes parts like valves, pumps, and bearings to ensure longer-lasting components are used.

Aerospace Industry:

In the aerospace industry, machines are used to coat base materials with a metal layer to ensure light-weighting and enhance corrosion and wear resistance in aircraft components.

Automotive Manufacturing:

In the automotive manufacturing industry, the electroplating machine coats automotive parts like trim, wheels, bumpers, and other exterior and interior components with chrome and other metals to enhance appearance and durability.

Production of Tools and Dies:

Machining and manufacturing industries use electroplating machines to coat cutting tools, dies, and molds with hard, wear-resistant materials to extend their service life and improve their cutting performance.

Producing Decorative and Functional Hardware:

Electroplating machines add a thin layer of metal onto the surface of locks, hinges, and knobs to improve corrosion resistance, conductivity, or to achieve a desired aesthetic appearance.

Electronics Industry:

Electroplating machines add a layer of gold, silver, or other metals onto electronic components, connectors, and circuit boards to enhance conductivity and solderability.

Size:

The size of the electroplating machine galvanizing will impact the amount of zinc that can be applied at one time. Larger machines may be more expensive to operate, but they can provide greater productivity for high-volume manufacturing applications.

Automation:

Some electroplating machines galvanize are fully automated, while others require manual input to control parameters like temperature and coating thickness. Determine how much labor you are able to dedicate to this process and consider whether an automated or semi-automated solution is more appropriate for your facility.

Cost:

The initial purchase price of the machine is an important cost consideration. In addition to the upfront expenditure, also evaluate long-term expenses like maintenance requirements, energy consumption, and any need for machine operator training to fully understand the total lifetime cost of the equipment.

Productivity:

How much production capacity does the electroplating machine deliver? The number of items processed per hour or day will influence your ability to meet manufacturing targets. Ensure the productivity level aligns with your operational needs while taking into account the feasible coating quality and adherence.

Flexibility: Electroplating machines vary in their ability to accommodate different parts shapes and sizes. Some have adjustable jigs and fixtures that allow for the processing of custom components, while others are only designed for specific geometries.

Maintenance:

Investigate the machine's maintenance requirements, including any scheduled service, replacement parts needed, and how user-friendly the equipment is. Consider whether your staff will have the time and expertise to perform routine upkeep of the plating devices.

Warranty:

Machines are often protected by a limited warranty that covers certain parts and issues for a defined period after purchase. Review the warranty terms carefully to understand what components are covered, if onsite service is included, and the length of the protection. This information will give insight into the machine's reliability and help safeguard your investment should repairs be required during the warranty timeline.

Q1: What are types of electroplating machines?

A1: The types of electroplating machines include barrel plating machines, rack plating machines, cathode bucket machines, line electroplating machines, and auto -rack plating machines.

Q2: What are the trends of electroplating machines?

A2: The global electroplating machine market is projected to indicate growth at a stable rate during the forecast period. The market is currently thriving owing to the rising demand from the automotive industry. The machine is used to manufacture essential parts and accessories of different vehicles.

Q3: Who uses electroplating machines?

A3: Several industries use electroplating machines for different applications. The automotive industry is the largest user of the machine. Also, the jewelry manufacturing industry depends on electroplating machines to coat pieces with gold and other precious metals. Moreover, the aerospace industry uses the machine to enhance aircraft components.