(8894 products available)

An electronic automatic counting machine can count various items, including coins, beans, bullets, cotton swabs, etc. Different models may adopt distinct technologies to achieve automatic counting.

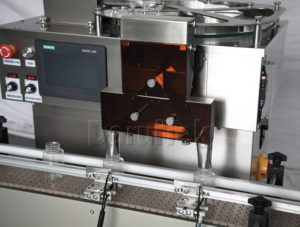

Optical sensor-based counters

Optical sensor-based counters use light beams and sensors to detect and count objects as they pass through a specific point or area. For example, a counting machine may install a series of light beams and sensors along a conveyor belt. When an item interrupts a light beam, the sensor detects it, registering the interruption as a counted item. This kind of counting method offers a high-speed count, making it appropriate for use in environments where items move rapidly.

Video-based automatic counting

This method uses video analysis and image recognition software to electronically count objects. For instance, a counting machine may utilize a video camera to capture a live video stream of a scene. Image recognition software then analyzes each frame and recognizes individual objects within the images, counting them accordingly. This technique offers flexibility and can be applicable in various settings, such as retail stores, public places, or event venues. It can also provide detailed information about object characteristics in addition to simple counts.

Mechanical counter

A mechanical counter automatically counts items using gears and levers. Mechanical counters are straightforward and reliable. When an counted item passes through the machine, it exerts force on a lever, which moves the gear to rotate and advance the count.

Tally counter

An electronic tally counter is a simple device used to count discrete events or objects. Tally counters typically have a display that shows the counted number and a push button to increase the count. Electronic tally counters can be handheld or fixed in place. The fixed automatic tally counter allows for hands-free counting; for example, in a counting machine, it may be possible to count each object by pressing the tally button with the counted objects.

The following are some core specifications of automatic counting machines.

Regular maintenance of an automatic counting machine is crucial to ensure its operational efficiency. Routine maintenance allows the device to function at peak performance while prolonging its lifespan. Set maintenance and care programs at frequent intervals to avoid breakdowns or costly repairs. Follow the manufacturer's maintenance instructions, and perform the following routine checks:

Electronic automatic counting machines are used in industries for different purposes as listed below.

Food Packaging:

Food factories or packing companies that deal with produce like fruits, veggies, nuts, snacks, and meat use counting devices to make sure each bag or box has the right amount of items. By doing this, they're ensuring that the packages are consistent, and employees can track the counts efficiently and accurately, which helps with customer satisfaction and quality control.

Pharmaceuticals:

In the business of making medicine, it's really important to count out pills and tablets precisely, especially when putting them into bottles. Automatic counting machines come into play here to help make sure that each bottle has got exactly the right number of pills in it, which is essential for both compliance with regulations and keeping customers happy. Using these machines reduces the chances of making mistakes and speeds up the process of packaging.

Currency Management:

In the world of banking, cash handling services, and ATMs, it's crucial to have a precise count of bills and notes. However, counting money by hand isn't efficient or error-free. That's where electronic automatic counting machines for counting bills and notes come in handy. These machines help in efficiently and accurately counting currency notes, whether they're brand new or old and worn out, saving time and reducing mistakes compared to manual counting.

Industrial Parts:

In big factories and assembly lines, small components and parts are produced in high volumes. Electronic counting devices are used to track and count precisely these tiny pieces, ensuring that the right amounts are delivered to the assembly lines. This helps keeping production flowing smoothly with no interruptions, which is essential for efficient manufacturing processes.

Electronics Manufacturing:

When making electronic products like mobile phones, computers, and other gadgets, it's important to have small parts like chips, resistors, and capacitors counted accurately while they're being used in the production process. Automatic counting machines play a crucial part in this by ensuring that these tiny components are counted precisely as they're needed, helping to streamline assembly and maintain high product quality.

When deciding whether to purchase a button counting machine or an industrial counting machine for one's business, it is advisable to consider the following parameters.

Data Requirement

Businesses have different electronic counting requirements. Therefore, it is essential to invest in a counting machine that suits their specific needs. Take time to evaluate the type of items the machine is to count and the desired level of detail and accuracy. Further, consider the amount of data that is to be processed and whether this data requires frequent update.

For example, a coin counting machine will obviously work for a scenario where a business is only counting coins. However, in a situation where a business counts different items, an industrial counting machine would work better.

Capacity and Speed

When purchasing a counting machine, ensure that its capacity and speed align with the counting needs of the business. Take time to consider the volume of items counted regularly and the processing speed required to maintain operational efficiency.

Technology and Features

Different counting machines have distinct technologies and features. Choose a machine that has the preferred technology and features. This will ensure it has the functions required to streamline the counting process.

Budget Considerations

Automatic counting machines come in different price ranges. Therefore, when considering to purchase one, it is advisable to set a budget and consider the potential return on investment. While some may have a lower acquisition cost, it is important to also consider their efficiency and the counting errors they can cause.

Q1: How does an electronic counting machine work?

A1: The working principle of the electronic counting machine varies depending on the specific type. Typically, it has a sensor system that detects items, followed by a data processing unit that records the detected items' numbers, and finally, a display showing the counted number.

Q2: What are the benefits of using an electronic counting machine in industrial and commercial settings?

A2: First, an electronic counting machine improves counting precision and efficiency. It can automatically count items instead of manual counting, which reduces the likelihood of errors. Second, the data processing and statistical functions of electronic counting machines can provide detailed information and analysis for businesses. Third, electronic counting machines are typically easy to use and operate, requiring only simple training to master.

Q3: Can an electronic counting machine be integrated with other systems, such as inventory management software?

A3: Many modern electronic counting machines support system integration. They can be connected to other software or systems through network protocols or application interfaces, facilitating data sharing and collaboration between different systems.

Q4: What kind of maintenance does an electronic counting machine require?

A4: Regular dust cleaning is vital to avoid data processing errors caused by excess dust. Also, routine inspections ensure all components function correctly and address any potential issues. Additionally, updating the software periodically will enhance the counting machine's performance and stability.