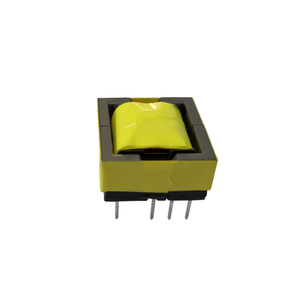

Introduction to EFD Bobbin

The EFD bobbin is a crucial component in a range of industrial applications, particularly in the textile, embroidery, and thread industries. It serves as a vital part of sewing machines and embroidery setups, ensuring smooth and efficient thread handling. Designed for optimal performance, the EFD bobbin minimizes thread tangling and breakage, thus enhancing the overall efficiency of sewing operations.

Types of EFD Bobbin

EFD bobbins come in various types, each designed to cater to specific machinery and applications. Understanding these types can help you choose the right bobbin for your needs.

- Standard EFD Bobbins: These are the most commonly used bobbins, compatible with a wide range of sewing machines.

- Heavy-Duty EFD Bobbins: Made from durable materials, these bobbins are designed for industrial applications where high thread tension is required.

- Pre-wound EFD Bobbins: Perfect for bulk sewing operations, these bobbins come preloaded with thread, reducing setup time significantly.

- Specialty EFD Bobbins: These include bobbins designed for specific functions, such as embroidery or quilting, featuring unique design elements for maximum performance.

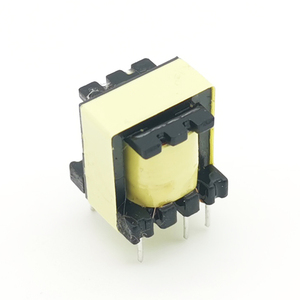

Function and Features of EFD Bobbin

The EFD bobbin plays a crucial role in the functionality of sewing machines, having several key features that enhance its performance:

- Thread Storage: EFD bobbins are designed to hold various types of threads securely, preventing tangling and loosening.

- Precision Winding: Each bobbin is engineered to ensure that the thread is wound evenly, which helps in maintaining consistent tension during sewing.

- Durable Materials: Constructed from high-quality plastics or metals, EFD bobbins are built to withstand the rigors of frequent use and support high-speed sewing operations.

- Compatibility: The designs of EFD bobbins make them compatible with a wide range of sewing machines, enhancing their versatility across different platforms.

Applications of EFD Bobbin

The versatility of EFD bobbins allows them to be used in a multitude of applications. Below are some of the primary areas where EFD bobbins excel:

- Textile Manufacturing: EFD bobbins are essential in textile mills, where they support the mass production of fabrics and garments.

- Embroidery: These bobbins are crucial for embroidery machines, allowing for intricate designs with varied thread colors.

- Quilting: In quilting, EFD bobbins aid in the layering and stitching processes, providing a sturdy foundation for excellent results.

- Crafting: Hobbyists and professionals alike utilize EFD bobbins for various crafting projects, ensuring the best quality stitching.

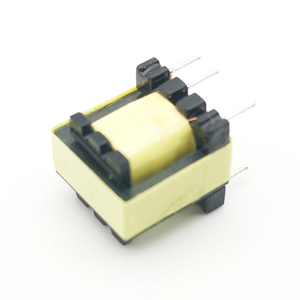

Advantages of Using EFD Bobbin

The adoption of EFD bobbins brings several advantages to both industrial and personal sewing tasks:

- Increased Efficiency: Reduced threading issues and tangles mean less downtime during projects.

- Consistent Quality: The precision design ensures uniform tension and even stitching, leading to high-quality outcomes.

- Cost-Effective: With durable construction, EFD bobbins tend to have a longer lifespan than conventional options, resulting in savings over time.

- Wide Availability: The popularity and compatibility of EFD bobbins mean they are readily available, making replacements and purchases convenient.